process of hemihydrate gypsum Somalia

The group reported that gypsum actually forms in a threestep process: precipitation of nanocrystals of bassanite — or calcium sulfate hemihydrate, with one water molecule for every two calcium sulfate units — followed by the assembly of those crystals into larger aggregates, and finally transformation of the aggregates into gypsumStable calcium sulfate hemihydrate is produced by suspending particulate gypsum in a reaction mixture comprising a water solution of a watersoluble inorganic salt such as a salt of an alkali metal, an alkaline earth metal or ammonium, and at least one of the group consisting of phosphoric acid and watersoluble phosphate salts; and heating the reaction mixture at a temperature and for a period of time sufficient to convert the particulate gypsum to particulate calcium sulfate hemihydrate PROCESS FOR PREPARING GYPSUM HEMIHYDRATE What is claimed is: 1 A method for producing αform gypsum hemihydrate, comprising contacting an exhaust combustion gas containing sulfur dioxide with an absorbent liquid containing at least 10100 mmol of magnesium sulfosuccinate per kg of the absorbent liquid and 5 to 25% by weight of gypsum dihydrate based on the absorbent liquid, subjecting to oxidation with air and to neutralization Process for producing αform gypsum hemihydrate Kureha

Hemihydrate an overview ScienceDirect Topics

25213 Manufacturing of gypsum binders The basic manufacturing operations of gypsum binders are preliminary preparation of the raw gypsum (crashing, drying and fine grinding), thermal treatment and additional grinding when required At each stage of the technological procedures, automatic control should be provided βHemihydrate binder The results showed that as soon as a stable gypsum nucleus is formed, hemihydrate hydration will proceed to its end and all the hemihydrate will become gypsum Once gypsum is present, the rate of the hydration can be slowed down but the process cannot be stoppedCalcium sulphate hemihydrate hydration leading to gypsum The properties of gypsum are influenced by the hydration process and the properties of the hemihydrate The hydration of hemihydrate such as the hydration kinetics and setting has been studied intensively so far , , , , , , , , but the emphasis was always laid on αhemihydrate Therefore topics such as the hydration induced properties, and especially the behavior of the βhemihydrate upon hydration to Microstructure and mechanical properties of βhemihydrate

Dihydrate reaction with gypsum and filter cakes by Prayon

This is a dihydratehemihydrate process During the first reaction stage, a pulp containing dihydrate is formed The amount equivalent to the acid to be produced is filtered The acid is then sent for storage, while the gypsum and the remaining pulp are sent to the conversion tank hemihydrate (872 g/l for βhemihydrate) /1/ The generated gypsum experiences a continuous change due to nucleation and precipitation, the volume fraction reads /2/ w m(0 ) g + + = h w h w n w v v v v w v v ϕ (2) Where φg is the volume fraction of gypsum, m hydration degree, vh/vw the Gypsum hydration: a theoretical and experimental study Looking for a New Process route: Di Attack – Hemi Filtration H 2 SO 4 98% Phosphate Recycled acid Water Hemihydrate Hemi Filtration 28% P 2 O 5 8% SO 3 Conversion Di Attack Filter Steam Hemi Filtration 3236 % P 2 O 5 3% SO 3New Development in Dihydrate Hemihydrate processes:

process of hemihydrate gypsum Somalia

PROCESS FOR PREPARING GYPSUM HEMIHYDRATE Stable calcium sulfate hemihydrate is produced by suspending particulate gypsum in a reaction mixture comprising a water solution of a watersoluble inorganic salt such as a salt of an alkali metal, an alkaline earth metal or ammonium, and at least one of the group consisting of phosphoric acid and watersoluble phosphate salts; and heating the New Development in Dihydrate Hemihydrate processes: The new Prayon DAHF process Tibaut Theys Prayon • Double crystal process • Gypsum seallable • Stacking issue solved • 90% of gypsum sold Dihydrate Process H 2 SO 4 98% Phosphate Recycled acid Water Dihydrate Typical P 2 O 5New Development in Dihydrate Hemihydrate processes: of gypsum has been carried out in water/gypsum suspension After the process of synthesis a product was filtrated and dried To evaluate mechanical properties (compressive strength) of αhemihydrate gypsum, from normal slurry consistence gypsum we have formed 2×2 cm cubes, which was determined by using Vicat apparatusHemihydrate Gypsum from Flue Gas Desulphurization

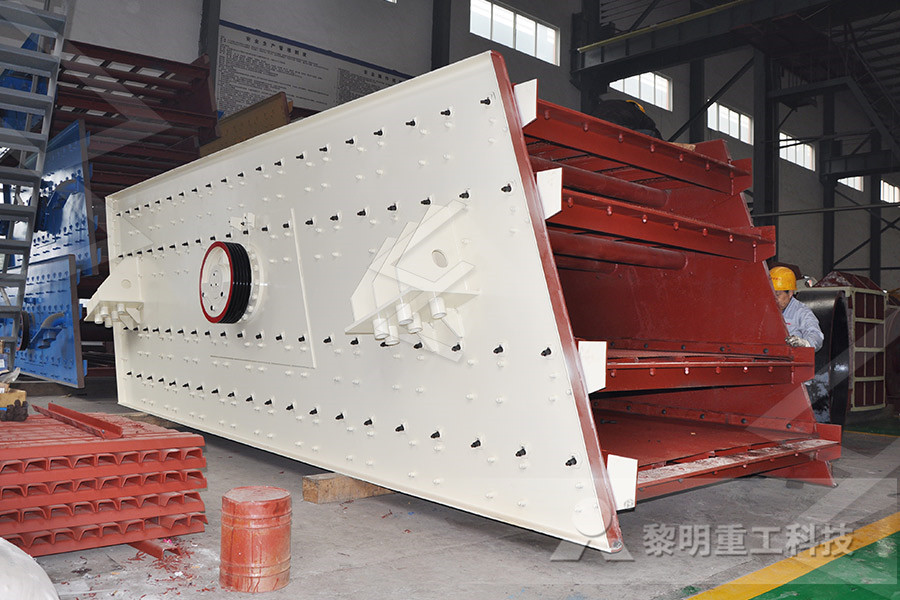

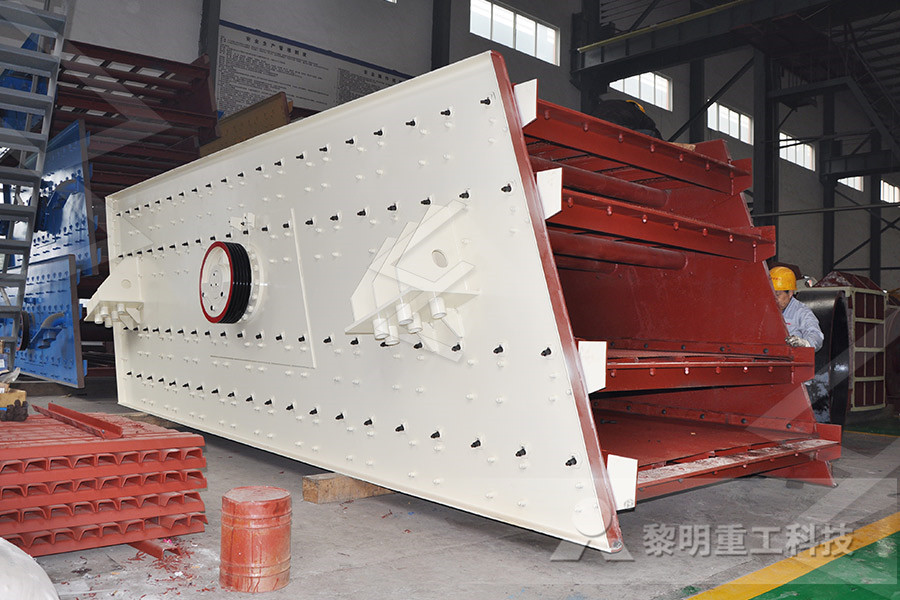

What is Gypsum How Gypsum is Processed MC

Use of Gypsum Gypsum is a widely used industrial material and building material Gypsum (CaSO 4 2H 2 O) can be calcined and grinded to obtain βtype hemihydrate gypsum (2CaSO 4 H 2 O), that is, building gypsum, also known as cooked gypsum or plaster The model gypsum can be obtained when the calcination temperature is 190 °C, and its fineness and whiteness are higher than that of The hydration of calcium sulphate hemihydrate (CaSO 4 05H 2 O) leading to the crystallization of gypsum (calcium sulphate dihydrate – CaSO 4 2H 2 O) has been the subject of several investigations over a long period and a vast amount of data is widely distributed throughout in the literature In this review article an overall picture of the subject is presentedCalcium sulphate hemihydrate hydration leading to The gypsum stone which was created from the hydration process out of αHH is characterized by its higher compressive strength and slower reaction 1 Introduction Calcium sulfate hemihydrate [CaCO 4 ∙ 05H 2 O(s)] can be found naturally in very dry climate regions in Egypt, Australia, Death valley and Kuwait as bassanite, but in the presence Investigation of hydration mechanisms Cement

Preparation of Whitening Dihydrate Gypsum and Short

Using FGD gypsum as the raw material, whitening and large prismatic dihydrate gypsum can be obtained by dissolution‐crystallization and decoloring process with α‐hemihydrate gypsum whiskers prepared in MgSO 4 ‐CaCl 2 ‐H 2 O solution, which can transform into whitening short columnar α‐hemihydrate gypsum process (x = 2, gypsum as the final crystal form) and the nondihydrate process (also known as the hemihydrate process because hemihydrate is involved, although it is not necessarily the final crystal form) The dihydrate process is the earliest developed Gypsum Crystallization during Phosphoric Acid Using FGD gypsum as the raw material, whitening and large prismatic dihydrate gypsum can be obtained by dissolution‐crystallization and decoloring process with α‐hemihydrate gypsum whiskers prepared in MgSO 4 ‐CaCl 2 ‐H 2 O solution, which can transform into whitening short columnar α‐hemihydrate gypsum The effects of aging temperature, pH, dosage of sodium dodecyl sulfonate Preparation of Whitening Dihydrate Gypsum and

Gypsum Flashcards Quizlet

Beta HemihydrateWhite in colorCalcining process: Open Kettle method heated rapidly until water of the crystallization process is driven offProduces a shattered crystalline structure which is porous, rough, and irregular in shapeUsed for the casts that wont be subject to severe handling or abrasive wearLeast complicated processing methodPROCESS FOR PREPARING GYPSUM HEMIHYDRATE Stable calcium sulfate hemihydrate is produced by suspending particulate gypsum in a reaction mixture comprising a water solution of a watersoluble inorganic salt such as a salt of an alkali metal, an alkaline earth metal or ammonium, and at least one of the group consisting of phosphoric acid and watersoluble phosphate salts; and heating the process of hemihydrate gypsum Somaliaof gypsum has been carried out in water/gypsum suspension After the process of synthesis a product was filtrated and dried To evaluate mechanical properties (compressive strength) of αhemihydrate gypsum, from normal slurry consistence gypsum we have formed 2×2 cm cubes, which was determined by using Vicat apparatusHemihydrate Gypsum from Flue Gas Desulphurization

New Development in Dihydrate Hemihydrate processes:

New Development in Dihydrate Hemihydrate processes: The new Prayon DAHF process Tibaut Theys Prayon • Double crystal process • Gypsum seallable • Stacking issue solved • 90% of gypsum sold Dihydrate Process H 2 SO 4 98% Phosphate Recycled acid Water Dihydrate Typical P 2 O 5Alpha Hemihydrate gypsum was prepared through atmospheric pressure salt solution method based on orthogonal experiments The morphology and phase composition of the samples were observed and analyzed by microscope and Xray diffractmeter The major experimental parameters of atmospheric salt solution that prepared alpha half water gypsum were determinedAlpha Hemihydrate Gypsum Preparationed by Without gypsum, hydrated calcium aluminate crystallizes within about 10 min; gypsum retards this process by several hours or even days depending on the gypsum content In the quality control of cement, it is therefore important to know the exact content of the CaSO4 dihydrate or hemihydrateDetermination of Calcium Sulfate Dihydrate and

Gypsum Crystallization during Phosphoric Acid

process (x = 2, gypsum as the final crystal form) and the nondihydrate process (also known as the hemihydrate process because hemihydrate is involved, although it is not necessarily the final crystal form) The dihydrate process is the earliest developed The main component is dihydrate gypsum (CaSO4 2H2O, DH) and the content generally reaches 90% [3], while it contains some impurities such as phosphate, fluoride, organic matters, et al [4,5] The preparation of hemihydrate gypsum (CaSO4 Hemihydrate Phosphogypsum MDPI When gypsum is converted to the hemihydrate, it will leave the reactor vessel In this report the conversion of gypsum to hemihydrate is set as 1, but in reality this of course would not happen If the conversion is 099, it would not be harmful because later on in the process the hemihydrate is converted back into gypsumGypsum boards from waste material: a cost effective

(IUCr) A kinetic and mechanistic study into the

βHemihydrate yields plasters for plasterboard production, pottery and ceramics (Sharpe Cork, 2006), and is produced on a significantly larger scale than αCaSO 4 05H 2 O Despite the great industrial importance of gypsum and its formation through the hydration of hemihydrates, remarkably little is known about this processBeta HemihydrateWhite in colorCalcining process: Open Kettle method heated rapidly until water of the crystallization process is driven offProduces a shattered crystalline structure which is porous, rough, and irregular in shapeUsed for the casts that wont be subject to severe handling or abrasive wearLeast complicated processing methodGypsum Flashcards Quizlet