Five steps to optimize crusher’s lubrication system

1 Monitoring of lube oil temperature A lot can be learned about a cone crusher by simply watching the supply oil temperature and comparing it to the return oil temperature Return oil temperature should be in the range of 60~140ºF (15~60ºC), although ideally in the range of 100~130ºF (38~54ºC) The lube oil should operate in a range between 10 and 50 degrees Celsius Operators should also implement a routine oil sampling program to effectively monitor oil and crusher condition, as the demanding operating conditions of this equipment can lead to sudden changes in performanceProper crusher lubrication Tip of the Week Lube optimal crusher lube oil temperature – Crusher South Africa optimal crusher lube oil temperature in Windhoek, Namibia When to use a synthetic grease ? Lubrication Oil and Barger Parts Inc ? Cone Crushers This entry was posted in Uncategorized Bookmark the permalinkrecommended oil for cone crusher worldcrushers

Gyratory Crusher Lubrication 911 Metallurgist

These of course indicate any fluctuation of the oil temperature or pressure A change in either of these could mean that a hearing is worn out, the oil level is to low, oil flow low, or perhaps dirty oil If the crusher is fitted with a water line to cool the oilTest oil pump interlock Crusher must not start when oil pump is off X Check the return line oil temperature:Oil must be at least 70 oF (21oC) before crushing beginsOil at return line must be less than 135 oF (57 oC) at all times X Listen for any unusual noises or vibrations after crusher is started X Check that feed is properly gradedget lubricating oil pump for crusher domyrolmexpl Temperatures below the recommended range increase lube oil viscosity leading to poor lubrication, increased wear, poor fuel economy, higher stress on pumps, valves, fittings, seals, and other components ThermOmegaTech®’s thermal bypass valves (TBVs) are ideal for these applications to maintain optimal fluid temperature in lube oil Lube Oil Systems Temperature Controlled Bypass Valves

operating temperature for crusher Mine Equipments

The Stone Crusher Maintenance Rock crusher On the other hand, each components of the stone crusher has its own range of the temperature in operation Therefore, the fellow two points should be Periodic oil sampling of the bearings is advised when oil lube is used The discharge conveyor and undercrusher hopper should be wider than the discharge width of the crusher Sufficient tension must be placed on the toggle plate to ensure proper alignment Fun fact In practice, many jaw crushers are not fed to their designed capacityTips to maximize crushing efficiency Pit Quarry : For a dualpurpose car, engine oil temperature needs to be at least 220 degrees F to burn off all the deposits and accumulated water vapor If engine sump What Is The Optimum Engine Oil Temperature? Hot

Keep Your Engine Alive: The Importance of Oil

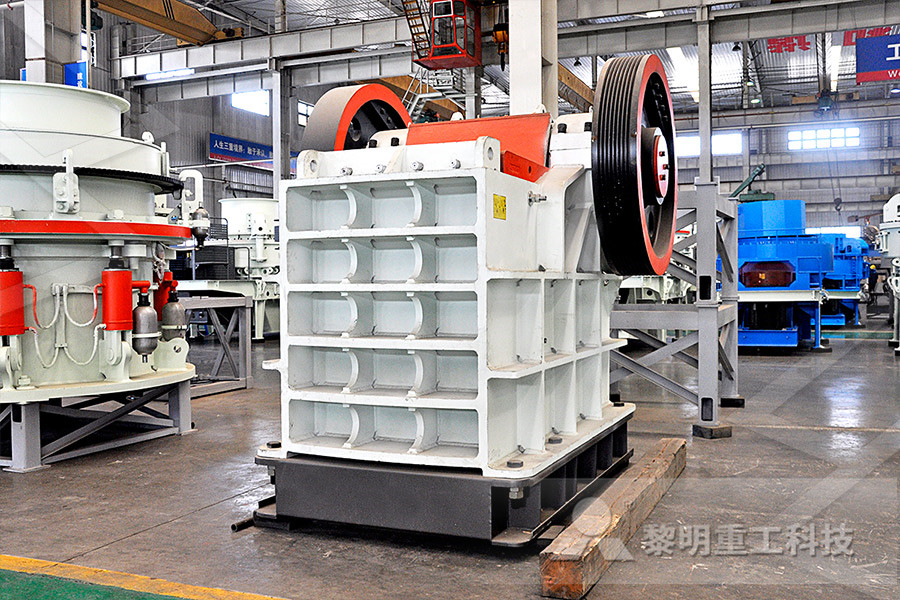

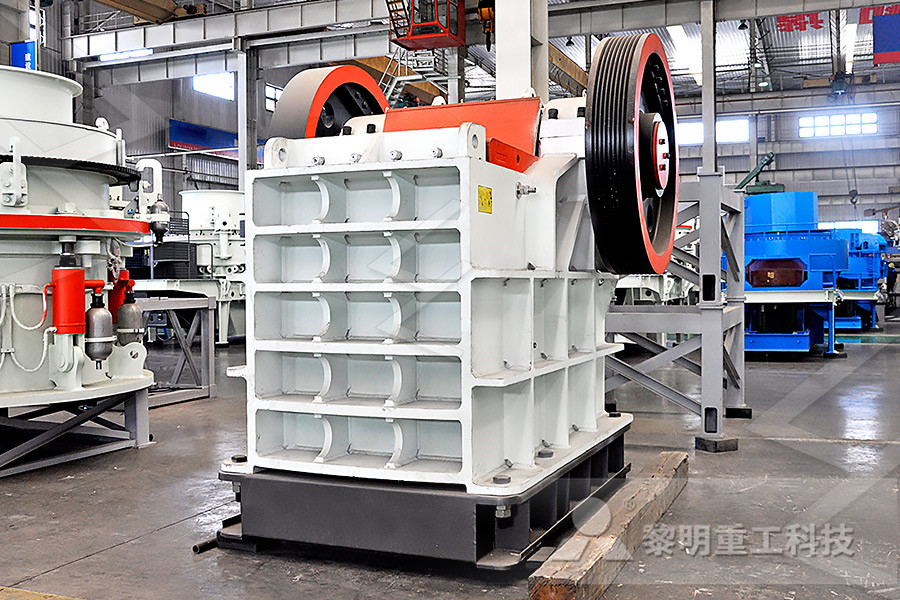

Oil temperature is probably the most important thing to know, specifically for those of us who are pushing our cars hard Free reving (or worse racing) on an engine that has not fully reached it's oil operating temperature is extremely dangerous But don't think that Periodic oil sampling of the bearings is advised when oil lube is used The discharge conveyor and undercrusher hopper should be wider than the discharge width of the crusher Sufficient tension must be placed on the toggle plate to ensure proper alignment Fun fact In practice, many jaw crushers are not fed to their designed capacityTips to maximize crushing efficiency Pit Quarry : Pit For this kind of crusher maintenance, you will need all kinds of temperature sensors, thermometers, oil pressure gauges, lubricating oil filter condition indicators, lube oil analysis reports, crusher drive motor powerdraw readings, and many, many moreWhat You Need to Know About Crusher Maintenance

crusher plant tons hour Crusher Machinery

optimal crusher lube oil temperature fire clay small roller crusher sat what is the cost of a ball mill equipements for granite mining cone crusher manufatura south africa shanghai machinery shanghai machinery manufacturers for sale permanent iron ore magnetic separator tymagnetic separator CONE CRUSHER Sandvik CH890i and CH895i are technologically advanced, highcapacity cone crushers designed for For optimal strength and less components requiring maintenance Oil temperature Oil flow Oil pressure Oil tank temperature Oil level Differential pressure across filter SANDVIK CH890i CH895i CONNECTED CONE CRUSHERHydraulic Cone Crusher>Hydraulic Cone Crusher For SaleSanway® Sanway® Hydraulic Cone Crusher with advanced hydraulic protection,easy operation and maintenanceYour specialist 7The lubricant system includes oil Cone Crusher Lubricants Crusher Mills, Cone Crusher, Jaw

Cone Crusher Allis Chalmers Parts In Namibia

Recommended Oil For Cone Crusher Worldcrushers Posted at October 30, 2012 47 3595 Ratings Cone crushers,China cone crusher,cs series cone crusher,Cone crusher optimal crusher lube oil temperature Crusher South Africa optimal crusher lube oil temperature in Windhoek, Namibia Live Chat; China Cone Crusher Products DirectoryFactors Eljay Cone Crusher Lube Pump Cone Crusher Factors Eljay Cone Crusher Lube Pump Cone crusher is used to crush various ore and stones within 350 MPa like Calcite, limestone, granite, river pebbles, dolomite, bluestone, glass, cement clinker, iron ore, etc Mining Machinery Specializing in the production of jaw crusher, sand machine, ball mill, Raymond mill, cement equipment and other jaw crusher lube point netwerkoostkampbe Lube Pkg – Air (Dry) 5,500 2,495 (Wet) 8,250 3,742 Automation Raptor® automated controls improve crushing performance by ensuring the cone crusher operates at optimal efficiency: • Available in five packages for all Raptor Cone Crusher models: • Reservoir with oil level sensor, temperature sensor and a thermowell mounted oil Raptor XL900 Cone Crushers

Raptor XL300 Cone Crushers

LubeAir Dry 1,515 690 Wet 2,140 970 LubeWater Dry 1,630 740 ensuring the crusher operates at optimal efficiency: • Available in five packages for all • Reservoir with oil level sensor, temperature sensor and a thermowell mounted oil heater Inspect gear drives to see if lube labels in place and proper lubricants used (especially conveyor back stops) Inspect gear drive lubricant sampling points Inspect gear drive temperature, cleanliness, breather condition, etc Compressors (shop or on a rotary rig) Check air intake (is location clean / optimal?) Check air/oil separators for leaksLube Assessment Mobil Periodic oil sampling of the bearings is advised when oil lube is used The discharge conveyor and undercrusher hopper should be wider than the discharge width of the crusher Sufficient tension must be placed on the toggle plate to ensure proper alignment Fun fact In practice, many jaw crushers are not fed to their designed capacityTips to maximize crushing efficiency Pit Quarry :

What You Need to Know About Crusher Maintenance

For this kind of crusher maintenance, you will need all kinds of temperature sensors, thermometers, oil pressure gauges, lubricating oil filter condition indicators, lube oil analysis reports, crusher drive motor powerdraw readings, and many, many more Viscosity of basic oil: generally defined in cSt (mm²/S) at 40°C density: approx 09 drop point: the temperature at which the first drop of a sample liquefied by heating drips Approximately: 180°C/260°C depending on the composition of the grease The maximum service temperature of the grease is always well below the drop pointINDUSTRY LUBRICATION NTN SNR Periodic oil sampling of the bearings is advised, when oil lube is used The discharge conveyor and under crusher hopper should be wider than the discharge width of the crusher Sufficient tension must be placed on the toggle plate to ensure proper alignment Efficiency tip Try to chokefeed any compressiontype crusherTips for maintaining efficiency in crushing circuits –

lubrication points of jaw crusher

Crusher Lubrication System Operation Maintenance For easy of Operation Maintenance, all Crusher Lubrication System include their own monitoring devices, SIGHT GLASSES or VIEW PORTS in the reservoir for oil level, FLOW METERS in the oil lines and/ or VISUAL ACCESS to the discharge point of the oil Factors Eljay Cone Crusher Lube Pump Cone Crusher Factors Eljay Cone Crusher Lube Pump Cone crusher is used to crush various ore and stones within 350 MPa like Calcite, limestone, granite, river pebbles, dolomite, bluestone, glass, cement clinker, iron ore, etc Mining Machinery Specializing in the production of jaw crusher, sand machine, ball mill, Raymond mill, cement equipment and other jaw crusher lube point netwerkoostkampbe Lube Pkg – Air (Dry) 5,500 2,495 (Wet) 8,250 3,742 Automation Raptor® automated controls improve crushing performance by ensuring the cone crusher operates at optimal efficiency: • Available in five packages for all Raptor Cone Crusher models: • Reservoir with oil level sensor, temperature sensor and a thermowell mounted oil Raptor XL900 Cone Crushers

Lube Assessment Mobil

Inspect gear drives to see if lube labels in place and proper lubricants used (especially conveyor back stops) Inspect gear drive lubricant sampling points Inspect gear drive temperature, cleanliness, breather condition, etc Compressors (shop or on a rotary rig) Check air intake (is location clean / optimal?) Check air/oil separators for leaks LubeAir Dry 1,515 690 Wet 2,140 970 LubeWater Dry 1,630 740 ensuring the crusher operates at optimal efficiency: • Available in five packages for all • Reservoir with oil level sensor, temperature sensor and a thermowell mounted oil heaterRaptor XL300 Cone Crushers1 天前 A temperature increase of 50°F (28°C) may cause oil viscosity to drop by 50% or more This could be the "tipping point" for the application, causing it to go from a hot (but stable) condition, to a hotter, unstable condition where thermal runaway occursSKF provides tips on troubleshooting bearing