whats the difference between granite crusher

difference between granite crusher and regular in pakistan whats the difference between crusher and granite crusher difference between granite crusher and regular What are the differences between a jaw crusher vs a cone crusher Sep 2 2015 As is well known Granite is one of the most using stone in aggregate crushing plant and artificial The Granite Crusher has an upgrade of a Ground Grinder where the Crusher does notWhat is the difference between granite crusher and Granite jaw crusher Get Latest Price Granite jaw crusher Feeding size: ≤1500 mm Discharging size: 25350 mm Capacity: 12200 t/h Granite jaw crusher is a new type of jaw crusher, which is developed by Fote Heavy Machinery based on the characteristics of granite It has a novel structure and a reasonable layout Video of granite jaw crusherWhich Type of Crusher is Suitable for Processing

Types Of Granite Crushers

For the treatment of different types of ore, different equipment is needed If the equipment is not properly selected, it will not only complete the processing of the ore, but also cause the equipment to wear out Granite is one of the common ores Here we introduceIn the crushing process, which type of crusher can be selected for the ore The common granite in daily life is mostly in construction In addition to construction, it can also be used in chemical, metallurgical, hydropower and other fields However, the newly developed granite has relatively large blocks and needs to be crushed Cone crusher is selected as granite The crusher is a very ideal choice, and the cone crusher is better in terms of output and granulationWhich crusher is most suitable for granite crusher Granite jaw crusher: If you want a granite crusher with big feeding size and long service life, the jaw granite crusher machine must be a good choice for you Granite impact crusher: Since the impact granite crusher machine enjoys the feathers of even discharging and threetime crushing in cavity, it is worth a recommendationGranite Crusher, Granite Crusher Machine, Granite

11 Differences Between Impact Crusher and Hammer

2 Different crushing cavities Impact crusher: It has a relatively large crushing cavity, so the material is not only impacted by the hammer, but also repeated impacts between the material and the impact plate, and between the material themselves Advantage: This kind of crushing is more sufficient and the bulk material can be better processed through itImpact crusher is mainly composed of reaction liner, feed port, plate hammer, rotor frame etc When the impact crusher is working, the plate hammers that distributed on the rotor according to different rules will hit the material on the reaction liner for crushing 2 Different Uses a Jaw crusher is a primary crusherJaw Crusher VS Impact Crusher What's The The small scale granite stone crusher was designed to crush stones of approximately 25135mm to about 24202mm in size SOLID WORKS was used as a stress analysis tool on the gear (main crushing part) to determine the regions where the gear experiences maximum force according to VonMisses failure criteriaDesign of a smallscale granite stone crusher

Difference Between Granite Crusher And Crusher

Building Crusher Fines Trails, Finely crushed compacted rock is a Fines from granite or other suitable hard stone works best An 8' wide contractor built crusher fine trail in the Denver area costs between $4 and $5 per foot, greater than 5% are required, consider using a different type of surfacing material Also, to meet different building requirement,the machine can separate different specifications cobblestones by circular vibrating screen from 12, 2448Vipeak Heavy Industry Granite Crusher is featured by high reduction ratio, high productivity, epigranular, simple structure, convenient maintenance, low production cost, and so onGranite CrusherGranite Crushing MachineGranite 3 Granite crushing plant layout and design Bulk granite from the material bin to the vibrating feeder, evenly fed into the jaw crusher of the primary crushing, then the output coarse crushed granite into the cone crusher of the secondary crushing process after the secondary crushing, the vibrating screen sieves the discharge from cone crusher, big granite need go back to the cone crushing Granite Crusher Stone Crushing Plant Design and

Fixed Crusher is a stone crusher equipment

Granite Fixed jaw crusher could reduce tough granite from various sizes down to 510mm, 1020mmm, and 520mm Limestone Limestone crushed to 510mm, 1020mm and 520mm shows high industrial value and diverse availability Gold mine Fixed crusher could crush gold mine down to 510mm, 1020mmm, and 520mm supplies granite crushing production line with the capacity ranges from 50t/h to 2000t/h applies two series of granite crushers to meet the different needs under different circumstances Cone crusher and mobile crusher series granite crushers are the ideal granite processing machines Mobile granite crushing plant itself is a Read granite small portable crusher Bussa MachineryC6X Series Jaw Crusher Output size : Depends on the material Production capacity : 1601500T/H Processed materials The C6X Series Jaw Crushers is most suitable for crushing the materials whose crushing strength lower than 320MP, like mineral, rock and slag, etccrusher, granite crusher, mobile crusher and mill

11 Differences Between Impact Crusher and Hammer

2 Different crushing cavities Impact crusher: It has a relatively large crushing cavity, so the material is not only impacted by the hammer, but also repeated impacts between the material and the impact plate, and between the material themselves Advantage: This kind of crushing is more sufficient and the bulk material can be better processed through itMining operations use different kinds of crushers so selecting the appropriate crusher is important for every operation Understanding the stages of crushing process and the types of crushers that best fit each stage can simplifies your equipment selection Each type of crusher is different and used to achieve a certain end resultRock Crusher Eastman Rock CrusherOur crusher machine has many different kinds and the application is also widely Jaw crusher is widely used in mining, smelting, building material, highway, railway, water conservancy and chemical industries and so on At present commonly used stone crusher include jaw rock crusher, impact crusher, hammer crusher, roll crusher, composite crusher and so onThe application of jaw crusher in different industry

Impact Crusher,Jaw crusher,Cone crusher

Due to the production requirements of different users, production environment is different, so the type granite of choose and buy mobile crushing station is equipped with is not the same, the specific price is judged according to the actual needs of users, and there is a certain timeliness, market prices so as mobile crushing plant produced 200 fference between granite crusher and crusher The difference between the two is the appearance and the working principle the principle of breaking is differentThe impact crusher adopts the principle of impact crushing after the material enters from the feed inlet, it is repeatedly crushed and crushed between the hammer and the counterattack plate until it is formed after moldingcrusher granite vs crushers Prominer (Shanghai) Also, to meet different building requirement,the machine can separate different specifications cobblestones by circular vibrating screen from 12, 2448Vipeak Heavy Industry Granite Crusher is featured by high reduction ratio, high productivity, epigranular, simple structure, convenient maintenance, low production cost, and so onGranite CrusherGranite Crushing MachineGranite

Granite Crusher Stone Crushing Plant Design and

Granite Crushing Plant Design and Crusher Machines Granite is hard rock with a saturated uniaxial ultimate compressive strength of more than 30 MPa For such hard rocks, the crushing plant always includes coarse crushing, mediumfine crushing, and shaping processes This paper briefly introduces the design of the granite processing line Impact Crusher is a stone processing machine used to process medium stone and soft stone This machine is used for mineral processing such as limestone, calcite, granite, barite, gypsy sum, concrete etc Impact Crusher is widely used in several types of work such as in mining, highways, railroad tracks, and some types of construction buildingsIntroduction of Impact Crusher Stone Machine IDT Granite Fixed jaw crusher could reduce tough granite from various sizes down to 510mm, 1020mmm, and 520mm Limestone Limestone crushed to 510mm, 1020mm and 520mm shows high industrial value and diverse availability Gold mine Fixed crusher could crush gold mine down to 510mm, 1020mmm, and 520mmFixed Crusher is a stone crusher equipment

Crusher for granite mining, quarrying plant News

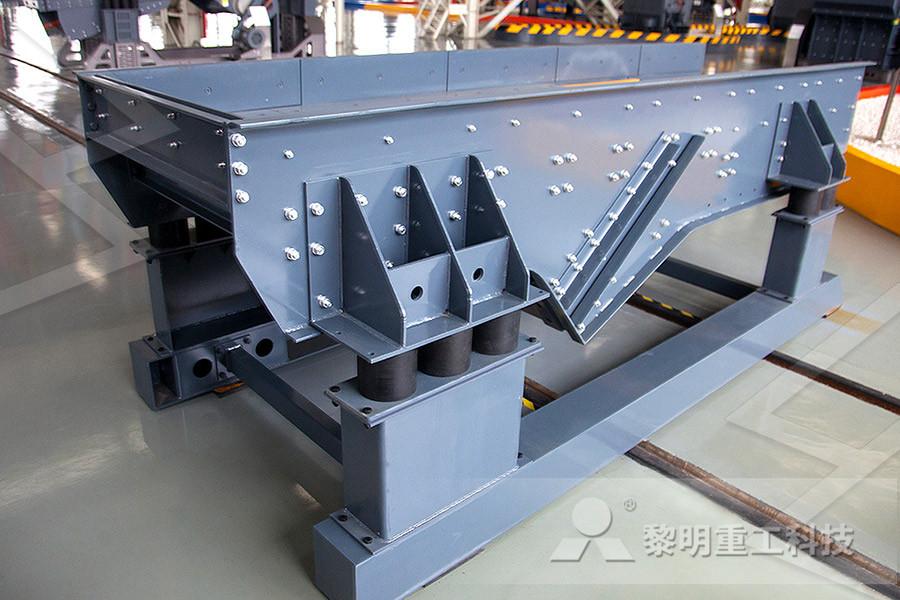

Granite crushing plant of our company mainly consists of Vibrating Feeder, Jaw Crusher, Cone Crusher or Impact Crusher, Vibrating Screen, Belt Conveyors and Control System, etc It is completely capable to crush and screen limestone, marble, granite, basalt, river stone and so on, and produce sand gravels with various granularities for Environmental Granite Rock Stone 600X900 Jaw Crusher Mar 14, 2021 PE 400X600 PE 500x750 PE 600x900 Stone Crushing Jaw Crusher For Primary Granite Crusher Application of Jaw Crusher: Bestlink Jaw crusher is a trusted and reliable brand for its high quality and good manufacturing:::China Jaw Crusher , Find details about China Jaw Crusher, Stone Crusher from Jaw Crusher Zhengzhou Unique what is the best granite crusher machineJaw crusher can crush all kinds of soft and hard materials with compressive strength between 300350Mpa, such as granite, quartzite, diabase, pebble, iron ore, etc Hammer crusher is mainly used to crush ores with low hardness, and its compressive strength is generally lower than 200Mpa, such as limestone, bluestone, coal gangue, etcHammer Crusher VS Jaw Crusher Which Is Better (7

Jaw Crusher With Different Models

Application fields The jaw crusher is a kind of early crushing device With simple and firm structure, reliable operation, easy maintenance and service and relatively low costs in production and construction, jaw crusher is still widely used in coarse, medium and fine crushing for various ores and rocks with compressive strengths ranging from 147 to 245 MPa in metallurgy, chemistry, building The purpose of the crushing process plant is to obtain different rock sizes or mineral mining JXSC has rich experience in the stone crusher plant layout and solutions Since 1985, We have successfully installed many stone production lines with different Crusher Plant Mineral Aggregate Processing