Component wear in vertical spindle mills grinding coal

The most important factor for coal is coal abrasiveness and for the mill is roll grinding pressure which give a very good combined correlation Using values in Table 6 the equation representing these results is of the form: War =0017(AIX GP)+18 (r=97%) Previous work on full scale mills (Sligar, 1986) showed a linear relationship between mill component wear and coal abrasivenessDrying and grinding are generally being done in either air swept ball mill or a vertical mill The selection of mill system will depend mostly on the factors like initial capital cost, drying and grinding capacity required, cost of energy (power) etc Coal Fineness: It is understood generally that the finer we grind, the easy it is for burning However, the fineness required will always be directed by where to fire and what type of Coal Grinding Cement Plant Optimization Grinding pressure can be adjusted to account for variations in coal grindability and desired product fineness Raw coal is fed through a centrally located feed pipe to the center of the grinding table As the flat grinding table rotates, coal is gradually forced out towards the edge where it passes underneath the rollersA Comparison of Three Types of Coal Pulverizers

Research on fault diagnosis of coal mill system based

In the operation process of the coal mill, there are many kinds of signals with high frequency, such as grinding current, vibration signal, grinding differential pressure and other signals Su et al [6] designed a system to record the vibration signals of the coal mill and transfer them into energy amplitudes by wavelet packet approach 6 The K St value, which represents the pressure rise velocity, or ∆P/∆t, can vary between 40 and 200 barms1This unit may look a little confusing, as one would rather expect a unit like bar/s, which would be easier to understand The reason for using the unit barms1 is that there is a need to classify fuels independently from the volumes of the enclosures in which they are being Explosion protection for coal grinding plants What Loesche coal grinding mills are distinguished by other characteristics that improve efficiency, safety and environmental protection, from the standard version to topoftherange installations: • Pressure shock resistance up to 35 bar (gauge) • Horizontal grinding table with segmented grinding track andLOESCHEMILLS

Coal Pulverizer 颇尔中国官网 Pall China

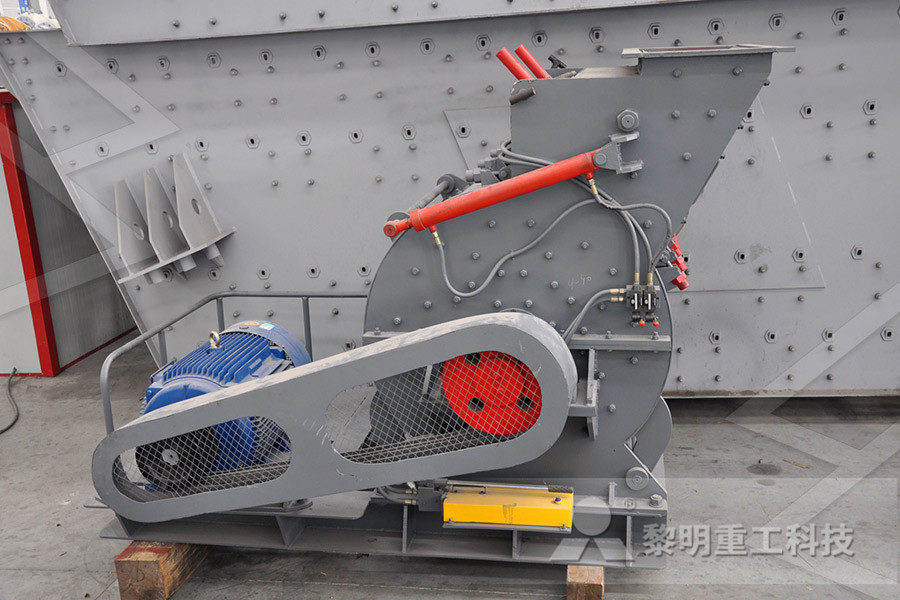

Grinding Action is carried out by a series of hinged or fixed hammers revolving in an enclosed chamber with wear resistant plates The hammers impact on the coal, crushing it against the plates Further pulverization is achieved as the smaller coal particles are ground through attrition against each other and the grinding face POLYCOM® highpressure grinding roll The proven energysaving grinding system One of the principal reasons for the outstanding success of the highpressure grinding roll in the cement industry is its low power requirement Today, this mill is employed all around the world for the grinding of cement raw material, cement clinker and granulated blastPOLYCOM highpressure grinding roll Explosibility of coal dust has been studied in laboratories, in explosion galleries and in an experimental coal mine The data and results obtained from the tests showed that finely pulverized coal dust has a lower explosive limit of 0035 to 008 ounces per cubic footCoal dust explosions and their prevention

grinding coal, grinding coal Suppliers and

Alibaba offers 5,096 grinding coal products A wide variety of grinding coal options are available to you, such as usage, local service location, and application Coal mill gypsum mill clay mill etc Pfeiffer MPS mills Three stationary grinding rollers roll on a rotating grinding table The material is drawn in between the rollers and grinding table and ground by pressure and shear The required pressure forces are produced by a hydropneumatic tension systemsaudi arabia high pressure grinding rolls coal EXPERIMENTS 2 1 Apparatus The new waterjet mill for coal grinding designed and built at the Mining and Mineral Engineering Department of the University of Cagliari is shown in Figure 1 Basically the system consists of: a Triplex High Pressure plunger pump capable of delivering a 54 l/min flowrate under a pressure of 250 MPaCoal grinding with water jets ScienceDirect

A Comparison of Three Types of Coal Pulverizers

It pulverizes coal by applying hydraulicallyloaded grinding pressure through three grin ding rollers onto a rotating bed of coal Grinding pressure can be adjusted to account for variations in coal grindability and desired product fineness Raw coal is fed through a centrally located feed pipe to the center of the grinding table The relationship between the specific capacity and the grinding pressure for a given coal was independent of feed size down to 150{mu}m However, smaller feed sizes produced anomalous results, and the flow within the feed hopper was restricted 10 refs, 11 figs, 4 tabs} journal = {Minerals and Metallurgical Processing} issue = {2} volume Capacity of highpressure grinding rolls (Journal Six US coals and a crystalline quartz were tested in an instrumented laboratory highpressure grinding rolls machine equipped with 100mmdiam rolls The machine was chokefed to maximize the capacity As expected, the specific capacity decreased with increased grinding pressure for each material tested Among the six coals, there were significant differences in the critical angle of nip, the Capacity of highpressure grinding rolls SpringerLink

Grinding Characteristics of Wood Pellet and Coal

To increase the cofiring ratio of biomass in existing pulverized coalfired power plants, coal and biomass should be pulverized to a suitable particle size for combustion In this study, the grinding characteristics of coal mixtures with different wood pellet (WP) ratios were evaluated using a benchscale roller mill The power consumption and differential pressure of the roller mill Calculation is based on the total geometrical volume of the coal grinding system (75% of silo net volume in case of two or more silos) Highpressure CO 2 inerting systems Highpressure CO 2 tanks have high inert gas capacities and compact tank dimensions They are mainly used in countries with large seasonal temperature fluctuations, such as Emergency inerting systems for coalgrinding Material is prevented from spilling over the edge of the dam ring as both the dam ring height and grinding pressure are adjustable The ATOX® Coal Mill’s efficient separator allows material that has reached the required fineness to leave the grinding mill and sends oversized material back for further grindingLonglasting coal mill for efficient grinding

The Effect of Grinding Time on DifficulttoFloat Coal

Coal is a valuable natural resource for economic development Clean coal and gangue can be liberated through grinding to improve the recovery of the clean coal In this study, the mineral composition, size distribution of the raw coal and the grinding time test were investigated The results showed that the main gangue minerals in the raw coal were kaolinite, quartz, illite, and smectiteAlibaba offers 5,096 grinding coal products A wide variety of grinding coal options are available to you, such as usage, local service location, and applicationgrinding coal, grinding coal Suppliers and Coal mill gypsum mill clay mill etc Pfeiffer MPS mills Three stationary grinding rollers roll on a rotating grinding table The material is drawn in between the rollers and grinding table and ground by pressure and shear The required pressure forces are produced by a hydropneumatic tension systemsaudi arabia high pressure grinding rolls coal

Capacity of highpressure grinding rolls SpringerLink

Six US coals and a crystalline quartz were tested in an instrumented laboratory highpressure grinding rolls machine equipped with 100mmdiam rolls The machine was chokefed to maximize the capacity As expected, the specific capacity decreased with increased grinding pressure for each material tested Among the six coals, there were significant differences in the critical angle of nip, the It pulverizes coal by applying hydraulicallyloaded grinding pressure through three grin ding rollers onto a rotating bed of coal Grinding pressure can be adjusted to account for variations in coal grindability and desired product fineness Raw coal is fed through a centrally located feed pipe to the center of the grinding tableA Comparison of Three Types of Coal Pulverizers pressure high pressure coal crusher usa pressure high pressure coal crusher usa As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable solutions for any sizereduction requirements including quarry, aggregate, and different kinds of mineralshigh pressure crusher coal usa Mining

Coal Grinding Mill Plant Manufacturers mulino

The Coal Grinding Mill Plant uses the pressure spring which can balance the pressurization function and the elastic connection which can play a stable shock absorption function It uses the lever principle to connect the symmetrical grinding roller assembly with the horizontally placed spring through the pull rod On the one hand, it reduces 6 The K St value, which represents the pressure rise velocity, or ∆P/∆t, can vary between 40 and 200 barms1This unit may look a little confusing, as one would rather expect a unit like bar/s, which would be easier to understand The reason for using the unit barms1 is that there is a need to classify fuels independently from the volumes of the enclosures in which they are being Explosion protection for coal grinding plants What To increase the cofiring ratio of biomass in existing pulverized coalfired power plants, coal and biomass should be pulverized to a suitable particle size for combustion In this study, the grinding characteristics of coal mixtures with different wood pellet (WP) ratios were evaluated using a benchscale roller mill The power consumption and differential pressure of the roller mill Grinding Characteristics of Wood Pellet and Coal

The Effect of Grinding Time on DifficulttoFloat Coal

Coal is a valuable natural resource for economic development Clean coal and gangue can be liberated through grinding to improve the recovery of the clean coal In this study, the mineral composition, size distribution of the raw coal and the grinding time test were investigated The results showed that the main gangue minerals in the raw coal were kaolinite, quartz, illite, and smectite In this design the grinding rolls are stationary, while the ring (or bowl, as it is sometimes called) is rotated by a worm gear drive Powerful springs force the grinding rolls against the ring, providing the pressure required to pulverize the coal Raw coal enters theCoal Pulverizer 颇尔中国官网 Pall China