raw mill of gypsum plant complete detail with images

Gypsum Grinding Mill Plant hcmilling Phrase one: raw material crushing Gypsum blocks will be crushed to 15mm50mm fineness by crusher Phrase two: Hong Cheng gypsum grinding mill enjoys high reputation in the industry, which not only benefited from Hong Cheng excellent product quality, but also inseparable with the service system of sincerity Gypsum processing equipment differs significantly in scale and level of technology some plants produce one or two tonnes per day using lowcost manual technologies, some other plants of a thousand tonnes per day that are highly mechanized and capable of producing different types and grades of gypsum plaster or plaster boardsGypsum Mining Processing Equipment Flow Chart Kiln And Raw Mill 33 Installation Of Cement Plant Kiln Kiln and raw mill 33 crusher plant requirements in africa this paper mainly introduces the raw mill in cement plant in order to achieve the desired setting qualities in the finished product, a quantity 28, but typically 5 of calcium sulfate usually gypsDetails; Kiln in cement plantkiln and raw mill installation of gypsum plant kiln

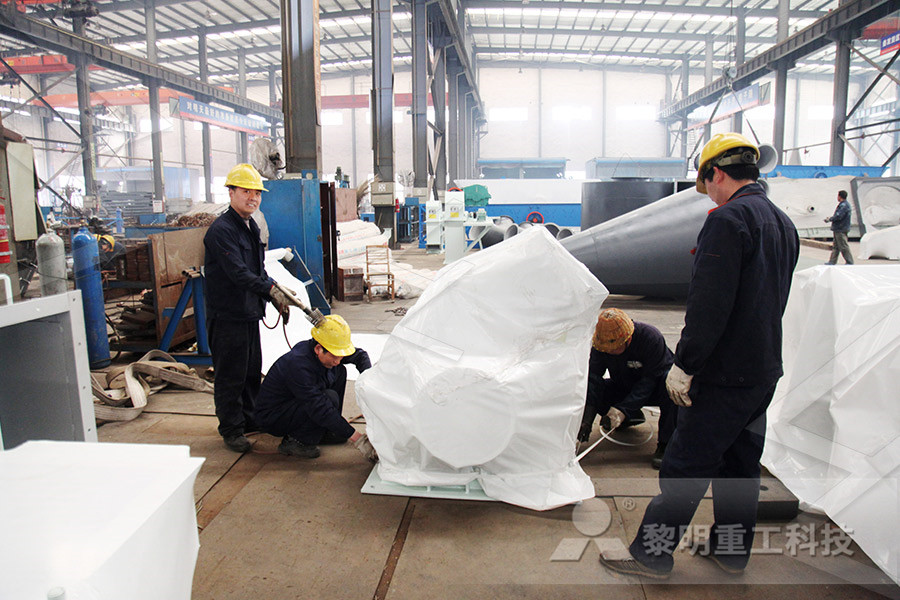

Grinding mill plant of gypsum Baichy

The production process of gypsum powder is divided into four steps: crushing, pulverizing, calcination, and storage and transportation Specific process: After being mined, the raw stone ore is crushed by a crusher and then lifted to a silo by an elevator, and then automatically fed by an electromagnetic vibrating feeder, and the material enters the cavity of the gypsum grinding mill 1116 Gypsum Manufacturing 11161 Process Description12 Gypsum is calcium sulfate dihydrate (CaSO4 2H2O), a white or gray naturally occurring mineral Raw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, and gypsum wallboard To produce plasters or1116 Gypsum Manufacturing US EPAClassification of Gypsum Gypsum usually refers to two kinds of minerals: raw gypsum and anhydrite Raw Gypsum is calcium sulfate dihydrate ((Ca (SO 4) 2H 2 O), also known as gypsum dihydrate, gypsum or gypsum, composition CaO (326%), SO 3 (465%), H2O+ (209%), monoclinic system, crystal is platelike, usually dense block or fiber, white or gray, red, brown, vitreous or silky luster, Mohs What is Gypsum How Gypsum is Processed MC

Calcining processes for natural and synthetic gypsum

The hammer mill, being a shorttime calcining system, grinds, dries, calcines and classifies the raw gypsum in a single step The resulting stucco is suitable for the production of plasterboard, gypsum fiberboard and gypsum wall blocks A hammer mill can process 100% moist FGD gypsum, 100% precrushed natural gypsum, or a mixture of bothRaw Meal Ball Mill Used For Cement Plant There are 384 raw mill system suppliers, mainly located in Asia The top supplying countries or regions are China, Turkey, and India, which supply 98, 1, and 1 of raw mill system respectively Raw mill system products are most popular in Southeast Asia, Eastern Asia, and South Asia Send Message Chat ball mill for raw mill in gypsum plant kwiatkowski Flue Gas Desulphurization Gypsum as a Raw Material building materials without harm to health Gypsumbased Building Materials II Technical Key Processes May 2728, 2010 FGD Gypsum as a Raw Material, »More detailedraw gypsum material processes sans Mining

raw mill process in cement plant netwerkoostkampbe

vertical raw mill, vertical raw mill Suppliers and Manufacturers cost of vertical raw mill in cement plant for oversea US $1000$7000 / Set 1 Set (Min Order) Xinxiang Great Wall Machinery Co, Ltd CN 7 YRS 1000% Response Rate Contact Supplier Therefore, in the production process, weGypsum Grinding Mill Plant hcmilling Phrase one: raw material crushing Gypsum blocks will be crushed to 15mm50mm fineness by crusher Phrase two: Hong Cheng gypsum grinding mill enjoys high reputation in the industry, which not only benefited from Hong Cheng excellent product quality, but also inseparable with the service system of sincerityraw mill of gypsum plant complete detail with images The production process of gypsum powder is divided into four steps: crushing, pulverizing, calcination, and storage and transportation Specific process: After being mined, the raw stone ore is crushed by a crusher and then lifted to a silo by an elevator, and then automatically fed by an electromagnetic vibrating feeder, and the material enters the cavity of the gypsum grinding millGrinding mill plant of gypsum Baichy

kiln and raw mill installation of gypsum plant kiln

Kiln And Raw Mill 33 Installation Of Cement Plant Kiln Kiln and raw mill 33 crusher plant requirements in africa this paper mainly introduces the raw mill in cement plant in order to achieve the desired setting qualities in the finished product, a quantity 28, but typically 5 of calcium sulfate usually gypsDetails; Kiln in cement plantCopper Plant Ball Millraw Materials Of Gypsum Board Energy saving ball mill,ball grinder,ball grindingenergy saving ball mill capacity 06290 t/h applicable material ball mill is key equipment for grinding materials after crushing processit is used to grind kinds of materials into fine powder 2075micrometerbased on discharging type, it could be grate typeAnd Raw Material Types For Ball Mill With Gypsum Gypsum processing equipment differs significantly in scale and level of technology some plants produce one or two tonnes per day using lowcost manual technologies, some other plants of a thousand tonnes per day that are highly mechanized and capable of producing different types and grades of gypsum plaster or plaster boardsGypsum Mining Processing Equipment Flow Chart

1116 Gypsum Manufacturing US EPA

1116 Gypsum Manufacturing 11161 Process Description12 Gypsum is calcium sulfate dihydrate (CaSO4 2H2O), a white or gray naturally occurring mineral Raw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, and gypsum wallboard To produce plasters or Design output According to customer needs Material Gypsum, chalk, clay, slurry and filter cake Application Heating Plant of limestone desulfurization project, stone powder maker for highgrade highways, coal grinding mill in environmental protection type boiler plant, the mill in mining firmsRaw Materials of Gypsum Board SHANGHAI SANME Gypsum Claudius Peters which move freely, like giant ball bearings, between the grinding rings In continuous operation, a material bed forms between these balls and the grinding ring but when the mill The Claudius Peters EM Mill is the preferred grinding and calcining technology for the production of finished products such as gypsum wallboard 4 calcining grindingball mill for raw mill in gypsum plant kwiatkowski

Innovative gypsum processing at GIPS AD –

The gypsum calcining systems are designed to process natural gypsum from the local underground gypsum quarries A greenfield project To take over production from the old three calcining kettles, the new calcining line was designed for a plaster capacity of 14t/hr, utilising a Claudius Peters EM 47568 Gypsum Calcining MillCement Raw Mill in Cement Plant for Cement Raw Meal Grinding The grinding of materials is more sufficient In the raw mill grinding process, the grinding material is discharged from the grinder through the discharge hole, and the fineness of the qualified material is sorted by the sorting equipment, while the fineness of the unqualified raw material mill process cement netwerkoostkampbe The production process of gypsum powder is divided into four steps: crushing, pulverizing, calcination, and storage and transportation Specific process: After being mined, the raw stone ore is crushed by a crusher and then lifted to a silo by an elevator, and then automatically fed by an electromagnetic vibrating feeder, and the material enters the cavity of the gypsum grinding millGrinding mill plant of gypsum Baichy

Processing Of Raw Gypsum For Cement Industry

Gypsum Processing stone crusher gypsum can be widely used in cement, building materials industry, Gypsum processing production process 1Raw material storage humidity gypsum plaster by Grinding mill plant of gypsum Grinding mill plant process introduction The production process of gypsum powder is divided into four steps: crushing, pulverizing, calcination, and storage and transportation Specific process: After being mined, the raw stone ore is crushed by a crusher and then lifted to a silo by an elevator, and then mill plant for gypsum okiempedagogaplRaw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, and gypsum wallboard A flow diagram for a typical gypsum process producing both crude and finished roller mill, where it is ground to the extent that 90 percent of it is less 149flow chart for process in raw mill building

ball mill for raw mill in gypsum plant kwiatkowski

Gypsum Claudius Peters which move freely, like giant ball bearings, between the grinding rings In continuous operation, a material bed forms between these balls and the grinding ring but when the mill The Claudius Peters EM Mill is the preferred grinding and calcining technology for the production of finished products such as gypsum wallboard 4 calcining grindingThe gypsum calcining systems are designed to process natural gypsum from the local underground gypsum quarries A greenfield project To take over production from the old three calcining kettles, the new calcining line was designed for a plaster capacity of 14t/hr, utilising a Claudius Peters EM 47568 Gypsum Calcining MillInnovative gypsum processing at GIPS AD – This paper mainly introduces the raw mill in cement plant In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form the finished cement powderRaw Mill In Cement Plant,Cement Making Plant

Gypsum Grinding Mill,Gypsum Grinding

India Gypsum Powder Processing Plant With Gypsum Powder Processing MachineRaymond Roller Mill From Clirik Gypsum powder grinding production line Gypsum powder has been used for a long time In the early days, it was simply used to make chalk, putty, tofu and simple handicrafts It has been widel CLIRIK Gypsum Processing Plant In India Aug 30, 2012 Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant There are also various other raw materials used for cement manufacturing For example shale, fly ash, mill scale and bauxite These raw materials are directly brought from other sources because of small ponents of raw mill used in cement plant The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow diagram below; 1 Quarrying and Crushing 2 Raw material Storage and Transportation 3 Proportioning 4CEMENT PRODUCTION AND QUALITY CONTROL A