large underground jaw crusher

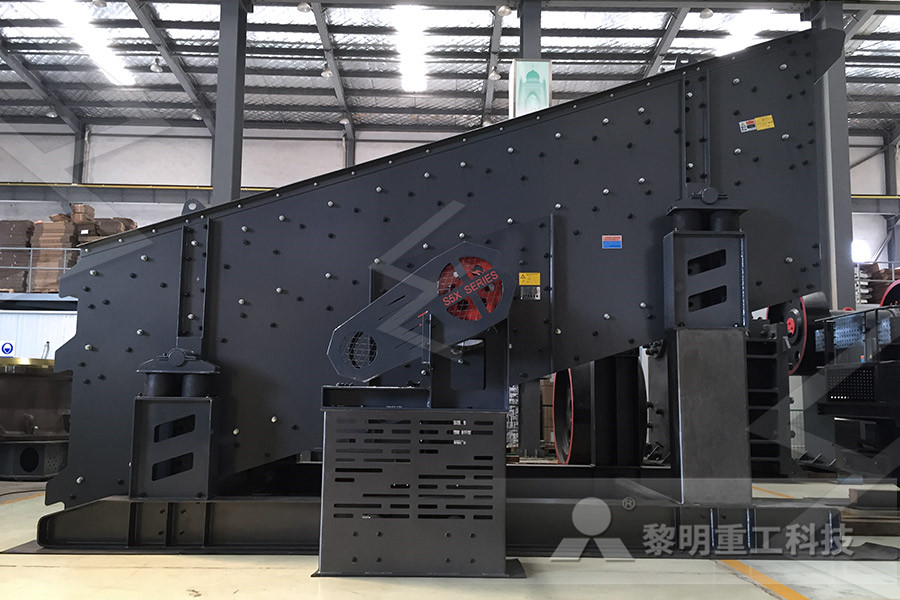

large underground jaw crusher Crusher Wikipedia, the free encyclopedia A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust Part For Jaw Crusher In Ore Mining,a crusher is a machine designed to reduce large rocks into smaller rocks, gravel, jaw crushers are installed underground in mines as well as on the surfaceLarge Underground Jaw Crusher,apr 5, 2011 1 introduction; 2 loion of the crusher in an underground mine the gyratory crusher consists of a wide opening that has a conical shapedPrimary Black Jaw Large Underground Jaw Crusher warberehounennlThe ultimate primary crusher The C Series jaw crushers are overhead eccentric single toggle jaw crushers The feed material is crushed between fixed and Inquiry Onlinelarge underground jaw crusher cafeunterdenlindende

Jaw crusher,large jaw crusher,jaw crusher price,jaw

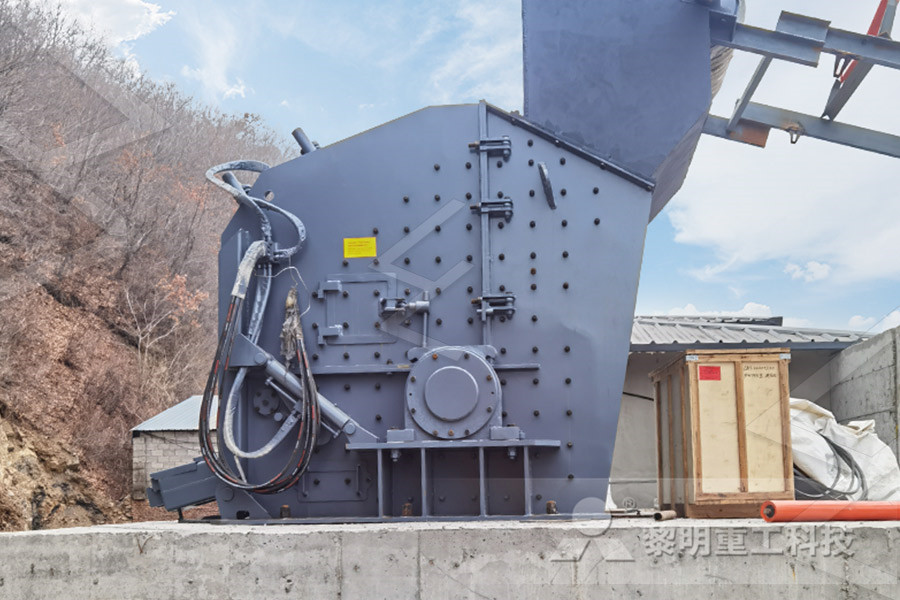

CJ Series Jaw Crusher Feed size :4251250mm Production capacity :501500t / h Crushing materials: limestone, sandstone, coke, coal gangue, raw coal, gypsum, slag, coke, etcApplications: Many sectors such as mining, metallurgy, JXSC jaw type rock crusher is usually used as a primary crusher and secondary crusher to reduce the size of mediumhard materials to smaller physical size Jaw rock crushers are capable of working with the mobile crushing station, underground Jaw Crusher Primary Crusher in Mining Aggregate JXSC ® C200™ jaw crusher is Outotec's largest jaw crusher model Due to its size, ® C200™ jaw crusher is most often utilized as a primary crusher for largescale aggregate production, and in mining applications on the surface and underground® C200™ jaw crusher Outotec

large underground jaw crusherdia domyrolmexpl

large underground jaw crusher India The Oak Tavern large underground jaw crusher large underground jaw crusher is one of the products of our company Get More Info; large underground jaw crusher ntgroupeu large underground jaw crusher Crusher Wikipedia, the free encyclopedia A crusher is a machine designed to reduce large rocks intoget price Currently, the dimensions of the largest Blaketype jaw crusher in use are 1600 mm × 2514 mm with motor ratings of 250–300 kW Crushers of this size are manufactured by Locomo, () and others The crusher is the C 200 series having dimensions 1600 mm × 2000 mm driven by 400 kW motors Table 41Jaw Crusher ScienceDirect Jaw crushers are the most common solution in underground applications when the throughput is below 1000 tonnes per hour, depending somewhat on the scalping Below the surface: Setting up an underground primary jaw

Underground Crusher Selection and Design Crushing

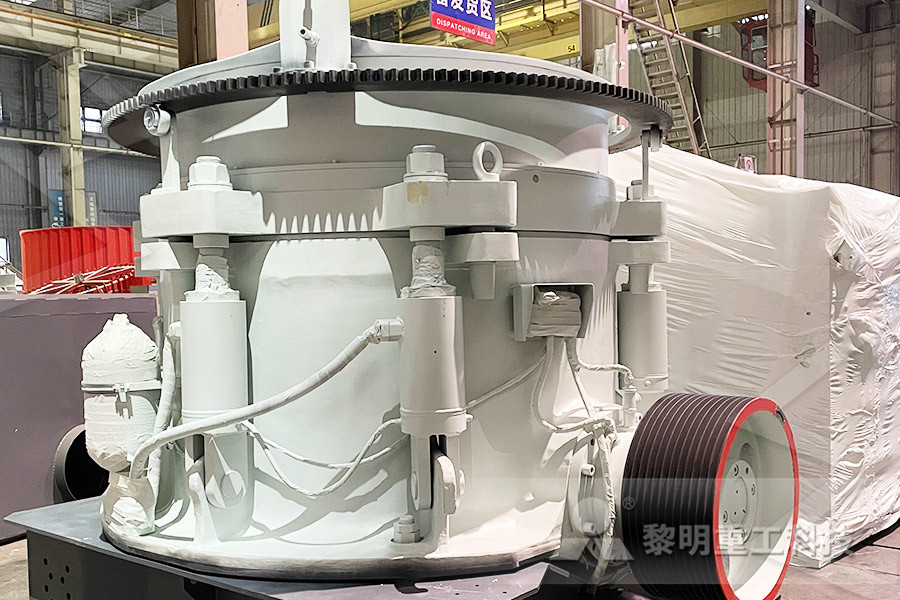

It depends on the type of ore and throughput Jaw Crushers may not be suitable for slabby ore, have low capacity and require heavy foundation because of the flywheel but they are easy to maintain unlike Gyratory crushers which are difficult to dismantle and very tall machines for underground Jaw Crusher vs Impact Crusher In short, the jaw stone crushers are mainly used for primary crusher, the crushing stone is relatively large The types of crusher machine's chamber are deep and no dead zone It improves that the feeding capacity and output The crushing ratio is large and the product particle size is evenJaw Crusher Primary Crusher in Mining Aggregate Alibaba offers 1,086 underground crusher products A wide variety of underground crusher options are available to you, such as local service location, key selling points, and applicable industriesunderground crusher, underground crusher Suppliers

Jaw Crusher With Different Models

Application fields The jaw crusher is a kind of early crushing device With simple and firm structure, reliable operation, easy maintenance and service and relatively low costs in production and construction, jaw crusher is still widely used in coarse, medium and fine crushing for various ores and rocks with compressive strengths ranging from 147 to 245 MPa in metallurgy, chemistry, building Jaw Crusher [Introduction] Crushing equipment with high production capacity, mainly used for preliminary crushing of stone [Productivity] 051590 t/h [Application] Jaw crusher is widely used for crushing various materials in mining, building materials, highways, railways, water conservancy and chemical industries [Improvement] The cavity and cavity shape of the crushing chamber are Jaw Crusher qxdali Russia’s leading mining equipment manufacturer and supplier Uralmashplant JSC (UZTM, part of the UZTMKARTEX Group) successfully completed factory tests recently of the first two domestically made jaw crushers with complex jaw swing (SCHDS range) manufactured for UMMC’s Gaisky GOK underground copper mining complex in Russia which is 280 km east of Orenburg near UZTMKARTEX's Uralmashplant develops new jaw

Jaw Crusher ScienceDirect

Largescale crushing operations are generally performed by mechanically operated equipment such as jaw crushers, gyratory crusher and roll crushers For very large ore pieces that are too big for receiving hoppers of mechanically driven crushers, percussion rock breakers or similar tools are used to break them down to size why C Series jaw crushers have a large eccentric throw coupled with a steep toggle plate angle that magni es the e ective stroke at the crusher discharge The large stroke, combined with the right speed, ywheel inertia and high vailable crusher power result in truly high crusher performance Operation at small settings as well as C Series jaw crushers cdnmachinemarket crusher configuration The feed material should be at least 20% smaller than the width of the feed open ing Arrangement drawing with fitting dimensions and loads on request Large feed opening 3,080 x 1,675 mm Jaw gyratory crusher for underground iron ore mining and the crushing chamber of a BK 6375 in a stationary copper ore plantIndustrial Solutions Gyratory crushers

Six ways to take primary crushing underground

The heaviest part of a C200 jaw crusher for maintenance is the pitman assembly, which weighs approximately 40 tons and requires 5 meters of vertical space plus clearances for liftingThe type of jaw crusher depends on input feed and output product size, rock/ore strength, volume of operation, cost, and other related parameters Heavyduty primary jaw crushers are installed underground for uniform size reduction before transferring the ore to the main centralized hoisting systemCrusher an overview ScienceDirect TopicsAlibaba offers 1,086 underground crusher products A wide variety of underground crusher options are available to you, such as local service location, key selling points, and applicable industriesunderground crusher, underground crusher Suppliers and

Jaw Crusher Primary Crusher in Mining Aggregate JXSC

Jaw Crusher vs Impact Crusher In short, the jaw stone crushers are mainly used for primary crusher, the crushing stone is relatively large The types of crusher machine's chamber are deep and no dead zone It improves that the feeding capacity and output The crushing ratio is large and the product particle size is evenJaw Crusher [Introduction] Crushing equipment with high production capacity, mainly used for preliminary crushing of stone [Productivity] 051590 t/h [Application] Jaw crusher is widely used for crushing various materials in mining, building materials, highways, railways, water conservancy and chemical industries [Improvement] The cavity and cavity shape of the crushing chamber are Jaw Crusher qxdali® C150™ jaw crusher is an effective jaw crusher in the 50ton (112 000 lbs) weight class It has been developed for the most demanding largescale mining and quarrying applications Crusher’s feed opening with long steep crushing cavity allows large coarse feed material up to onemeter (40”) size® C150™ jaw crusher Outotec

Jaw Crusher Mineral Processing

Jaw crusher is a robust size reduction equipment designed to reduce large solid materials into smaller particles, widely used in the quarrying, metallurgical and allied industries Jaw crusher is one of the most commonly used primary crushers in the ore processing plant, with the capacity range of 11000tphJaw Crusher Underground Jaw Crusher Design Calculation Processing capacity:461900t/h Feeding size:1871141mm Appliable Materials: river pebble,calcite,quartz,concrete,dolomite,construction rubbish,cobblestone,basalt and all kinds of hard and soft ores with compressive strength notunderground jaw crusher design calculation why C Series jaw crushers have a large eccentric throw coupled with a steep toggle plate angle that magnifies the effective stroke at the crusher discharge The large stroke, combined with the right speed, flywheel inertia and high vailable crusher power result in truly high crusher performance Operation at small settings as well as C Series jaw crushers

Crushers QueensMineDesignWiki

•Installation of an underground jaw crusher may cost up to six times as much as the crusher itself • A 48 by 60 jaw crusher produces approximately 18 tons per horsepowerhour (22 t/kWh) at a 6:1 reduction ratio (de la Vergne, 2003) Dust Control Throughout the process of crushing, large amounts of dust are produced The heaviest part of a C200 jaw crusher for maintenance is the pitman assembly, which weighs approximately 40 tons and requires 5 meters of vertical space plus clearances for liftingSix ways to take primary crushing underground Australian Install jaw gyratory crusher underground jun 3 primary rock crushing parker plant jaw crushers are used mainly in first stage reply crusher wikipedia a gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant gyratory how to Outotec launches compact large The crusher was born out of a need for a high underground gyratory crusher in vancouver