Nickel Ore Processing Magnetic Separation Aquacristal

Nickel Ore Mineral Processing Nickel ore mainly consists of coppernickel sulfide ore and nickel oxide ore, beneficiation and processing of both methods is completely different Coppernickel sulfide ore beneficiation methods: The most important is theflotation The magnetic and the gravity separation is usually secondary dressing method In this case, the higher magnetic field strength results in a much higher mass pull to the magnetic product compared to the dry, low magnetic case discussed above Roasting at 650 °C in the presence of coke breeze reduced the amount of hematite present, but increased the amount of magnetite causing the weight of magnetics to almost reach 90%Preconcentration strategies in the processing of nickel Processing: For selecting, recycling , removing iron ( fe) 4 Capacity: 05t/h, 1~5t/h, 5~10t/h, 10~30t/h, and so on 5 Voltage in China: Three phases: 380V/50Hz, we can make it according to customers' Local voltage according to different countries Features of Nickel Ore Magnetic Separation Plant/Iron Ore Magnetic Separation Plant 1 No Nickel Ore Magnetic Separation Plant/Iron Ore

Nickel Ore Beneficiation Plant Nickel Ore Processing

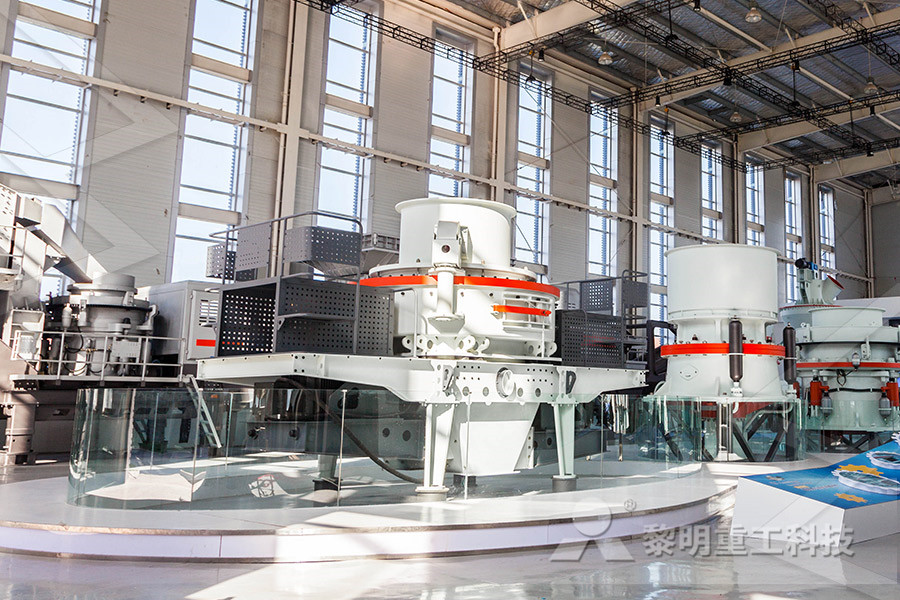

Nickel Ore Processing Equipment Star Trace Nickel Ore Processing uses the following equipments for the entire process: Hydrocyclone, Dewatering Screen, Magnetic Roll Separator, Belt Conveyor, Sand Washer, Screw Classifier, Spiral Separator, Concentrating Table, Dryer, Density Separator, HT Separator, Cooler Nickel processing, preparation of the metal for use in various products Although it is best known for its use in coinage, nickel (Ni) has become much more important for its many industrial applications, which owe their importance to a unique Nickel processing BritannicaNickel Ore Processing Plant Star Trace offers turnkey solutions for nickel ore processing plants We are one of the leading project suppliers for nickel ore plants and we work closely with our customers to fulfill their specific needs for a customized packaged solutionNickel Ore Processing Plants Nickel Ore Processing

nickel Ore SlideShare

nickel Ore 1 Nickel Ore Processing Prepared By Mukesh Ranjan Behera 1 2 CONTENTS What is Nickel Nickel Physical and Chemical Properties Nickel History and Indian Nickel Market Formation of Nickel and its Types Processing Options relative to deposit type Laterite Ore Processing Sulfide Ore Processing Nickel processing Nickel processing Extraction and refining: The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes and equipment are used The major differences in equipment Nickel processing Extraction and refining Britannica Extraction of Nickel This paper introduces the extraction of nickel process and characteristics of laterite nickel ore dressing, highlights the nickel ore crushing, washing in the nickel production process design 1 Description of nickel ore The laterite nickel ore is complex in composition and can be roughly divided into two types: limonite type and silicon magnesiumnickel typeExtraction of Nickel Nickel Ore Mining Mining

Nickel ore Magnetic Seperation nuuipl

01112020 The magnetic separation efficiency of nickel from the laterite ore was evaluated using the recovery ratio of nickel R ni using the formula: (1) R Ni = m Ni × β Ni M Ni × γ Ni × 100 % where m Ni is the mass of the magnetic product, g; β Ni is the nickel content in the magnetic product, wt%; M Ni is the mass of the reduction Nickel ore divides into copper sulfide and copper oxide ore , the main process for copper sulfide is flotation , magnetic and gravity separation is the subsidiary process It is a high technological enterprise that integrated research , manufacture, sales and service The company has multiple subsidiaries such as Mineral Processing Research InstituteNickel Ore processing Yantai Jinpeng Mining Nickel ore divides into copper sulfide and copper oxide ore , the main process for copper sulfide is flotation , magnetic and gravity separation is the subsidiary process ,It is a high technological enterprise that integrated research , manufacture, sales and service The company has multiple subsidiaries such as Mineral Processing Research InstituteNickel Ore ProcessingYantai Jinpeng Mining

Nickel Mines, Nickel Extraction Process, Nickel

[Introduction]: Nickel ore can be divided into copper sulfide nickel ore and nickel oxide oreFlotation is the main beneficiation method when processing copper sulfide nickel ore, and magnetic separating and gravity separating are the commonly auxiliary methods Nickel processing Nickel processing Extraction and refining: The extraction of nickel from ore follows much the same route as copper, and indeed, in a number of cases, similar processes and equipment are used The major differences in equipment are the use of highertemperature refractories and the increased cooling required to accommodate the higher operating temperatures in nickel Nickel processing Extraction and refining BritannicaExtracted ore is stored temporarily in piles before transporting for crushing and separating The magnetic portion of the ore (concentrate) is led to the stacker system and on to the homogenization yard The homogenized ore is loaded and transported to the smelting plant, where it is weighed and fed to the kilns for further processing SmeltingLARCO GMMSA Nickel

Nickel Geoscience Australia

Processing After mining, nickel ores are further processed to upgrade their nickel contents from 14% typical of the ores to concentrates with grades in the range 1020% Concentration involves crushing the ore and separating nickelbearing from other minerals using various physical and chemical processing methods Extraction of Nickel This paper introduces the extraction of nickel process and characteristics of laterite nickel ore dressing, highlights the nickel ore crushing, washing in the nickel production process design 1 Description of nickel ore The laterite nickel ore is complex in composition and can be roughly divided into two types: limonite type and silicon magnesiumnickel typeExtraction of Nickel Nickel Ore Mining Mining Copper Nickel Ore Flotation Process When process coppersulfide nickel ore, collector and frother will be used in order to better results A basic principle of coppersulfide nickel ore process is that it is better to let copper assimilate into nickel ore rather than the opposite For it is easier to recovery cooper from nickel concentrateNickel Ore Mining Process eventhauskarlsruhede

Nickel Ore Accrue Group Holdings

Nickel is an extremely important commercial element, playing a key role in global industrial development and outpacing almost all other industrial metals The factors which make nickel and its alloys valuable commodities include strength, corrosion resistance, high ductility, good thermal and electric conductivity, magnetic characteristics and 01112020 The magnetic separation efficiency of nickel from the laterite ore was evaluated using the recovery ratio of nickel R ni using the formula: (1) R Ni = m Ni × β Ni M Ni × γ Ni × 100 % where m Ni is the mass of the magnetic product, g; β Ni is the nickel content in the magnetic product, wt%; M Ni is the mass of the reduction Nickel ore Magnetic Seperation nuuipl Processing After mining, nickel ores are further processed to upgrade their nickel contents from 14% typical of the ores to concentrates with grades in the range 1020% Concentration involves crushing the ore and separating nickelbearing from other minerals using various physical and chemical processing methodsNickel Geoscience Australia

LARCO GMMSA Nickel

Extracted ore is stored temporarily in piles before transporting for crushing and separating The magnetic portion of the ore (concentrate) is led to the stacker system and on to the homogenization yard The homogenized ore is loaded and transported to the smelting plant, where it is weighed and fed to the kilns for further processing Smelting Copper Nickel Ore Flotation Process When process coppersulfide nickel ore, collector and frother will be used in order to better results A basic principle of coppersulfide nickel ore process is that it is better to let copper assimilate into nickel ore rather than the opposite For it is easier to recovery cooper from nickel concentrateNickel Ore Mining Process eventhauskarlsruhedewaste in nickel ore processing can be realized Sodium sulfate is commonly used as an additive in the selectivereduction of nickel ore processing Jiang et al (2013) reported that the addition of 10 wt % of sodium sulfate and 2 wt% of coal in the reduction of nickel ore containing 149% Ni at 1200ºC forPAPER OPEN ACCESS 7KHUROHRIVRGLXP

Factors Affecting the Upgrading of a Nickeliferous

leaching methods have been employed [7] Nickel bearing ore is leached with sulphuric acid in an autoclave, followed by the recovery of nickel metal from the solution by electrowinning or hydrogen reduction A high purity nickel metal can be produced by this method, and nickel recoveries are typically in the range of 90% to 92% [8] 1,000 tpa nickel as mixed nickelcobalt hydroxide (MHP) from 12,000 tpa of nickel sulphide concentrate byproduct from their talc mining operations, previously sold to smelters Construction was completed in 2015, and the plant is currently being optimized and ramped up to full production (5) The bioleaching technology isALTA MetBytes Bioleaching Moves into Nickel HYDROMETALLURGICAL APPROACHES: (Cu₈Ni₁₆Fe₁₀)→Limonite (FeO(OH)nH₂O) • Solvent Extraction – Electrowinning approach to lateritic ore beneficiation, is a hydrometallurgical method that relies on leaching, extractants, and electrowinning to produce nickel from ore Heap leaching is an industrial mining process to extract precious Nickel and its extraction SlideShare

Nickel Metal: It's Properties, History, Production Uses

History Baron Axel Fredrik Cronstedt first extracted pure nickel in 1751, but it was known to exist much earlier Chinese documents from around 1500BC make reference to 'white copper' (baitong), which was very likely an alloy of nickel and silverFifteenthcentury German miners, who believed they could extract copper from nickel ores in Saxony, referred to the metal as kupfernickel, 'the Nickel is an element and a material added by various mods 1 Vanilla 2 Embers 3 Extra Bees 4 Factory Tech 5 GregTech 5 51 See also 6 Immersive Engineering 7 MineChem 8 Mystical Agriculture 9 Tech Reborn 10 Thermal Foundation 11 Thermal Expansion 3 As added by Vanilla Main article: Nickel on the Minecraft Wiki As added by Embers Nickel spawns as an ore between Y=0 and Y=24 As Nickel Official Feed The Beast Wiki