how is gold crushed in mineral processing

Gold extraction refers to the processes required to extract gold from its ores This may require a combination of comminution, mineral processing, Normally, the ore is crushed and agglomerated prior to heap leaching High grade ores and Get Price; Gold processing Britannica Gold processing, preparation of the ore for use in various productsGold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that extensive mineral processing cannot economically be justifiedhow is gold crushed in mineral processinggold processing from crushed rocks How Is Gold Crushed In Mineral Processing Processing flow01The crushing sections the gold ore from the mine site is always with size 0400mm or 0600mm after blastingWe use the crushing plant to crush the raw gold ore into 08 or 010mm02Primary grinding and classifying section the gold ore with the size 08mm or 010mm How Is Gold Crushed In Mineral Processing

how is gold ore crushed process ataFinch

how is gold ore crushed process Once theorehas been broken up into fine dust, testing for freegoldcontent in hardrockorecan be done using some type of gravity method A simplegoldpan can be used to sample small amounts ofcrushed ore, or if a decent water supply is available then it can be run through many types of separation deviceshow is gold ore crushed process icsfalconeborsellino how is gold ore crushed process Gold Mineral Fact Sheets Australian Mines Atlas The processing required to recover fine gold from crushed ore is the gold is recovered from the goldbearing solution in a process in whichhow is gold crushed mineral processinghow is gold crushed in mineral processing Test Gold how to articles and videos including Walkthroughs for "Mace: The Dark Age" on N64, How to Identify European Gold Makers' Marks, How to Identify Gold DustIn the gold ore crushing process, jaw crusher is used as Read morehow is gold ore crushed process

Introduction to Mineral Processing or Beneficiation

The most common and notable example of this are precious metal values (gold, silver etc) where the beneficiation process is applied directly on runofmine ores followed by the extraction of gold and in some cases silver as a relatively pure metal within the mineral processing circuit 20 Processing Gold processing has a couple of unique features The first is the sheer variety of the mineralogical characteristics and associations, which is what this article is Gold processing 101 Mining Magazine Gold CIL processing plant Carbon in Leach (CIL) process is widely used in the mining industry and in particular, it is an integral step of gold processing in gold extraction Normally the CIL process can concentrate gold from 25–35 g/t in ore to 2000 to 6000 g/t on carbonCIL Gold Mining Solution Mineral Processing

Milling Mineral Processing Extractives Hub

Crushed ore is fed into Mills in which the ore is mixed with water and may be ground down to a particle size, in the case of gold and copper, of about 75 microns (0075mm) The fine, powdered ore emerges from the mills mixed with water in a thin, wet paste called Pulp or SlurryCrushing in Mineral Processing In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocksmineral processing crushing of gold【Process Introduction】 Heap leaching (HL) is a flexible and economic mineral processing method, commonly used to extract gold from lowgrade gold ores In this process, ore is firstly crushed to fine particles By spraying leaching solution to the large piles, the goldcontaining solution is leachedGold Heap Leaching Process Mineral Processing Plant

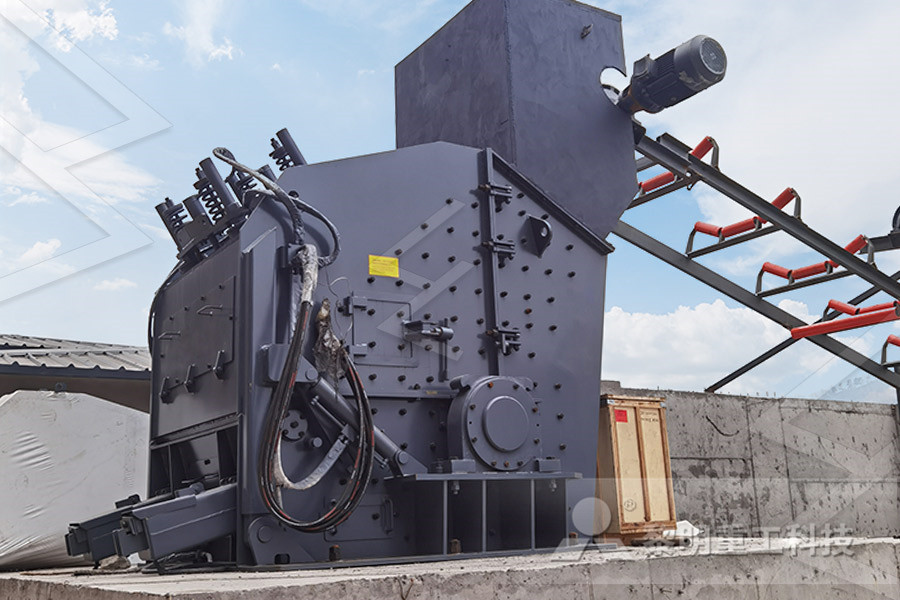

Crushing in Mineral Processing 911 Metallurgist

In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface Gold is often found associated with the mineral quartz It is sometimes associated with other minerals as well, including iron and manganese oxides, calcite, pyrite and other sulfides as well It is not uncommon for prospectors, especially those who operate metal detectors , to find a rich gold bearing specimens of oreRock Crushing methods and How to recover gold from Ores Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that extensive mineral processing cannot economically be justified In this case they are merely shattered by explosives and then piled into heaps for Gold processing Mining and concentrating Britannica

Mineral processing metallurgy Britannica

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyThe primary operations are comminution and concentration, but there are other important operations Crushed stone: natural rock (mostly rock) is crushed and sieved by mining machinery The size of crushed stone is often larger than 475mm, and the surface is rough and angular 2Source comparison Gravel: usually found in deposits containing sand, mainly excavated from sediments in What is the difference between gravel and crushed stoneMineral processing metallurgy Britannica Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue It is the first process that most ores undergo after mining in order to provide a more concentrated material for the procedures of extractive metallurgyget priceore processing crushed

crushed limemineral plant process gondwanauniversity

Crushing in Mineral Processing Mar 19, 2017 Crushing in Mineral Processing Post navigation Previous Next In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock to be crushed, there are 2 largely different techniques at your disposition for Tailings Mineral Industry Solution Magnetite is mined in large chunks and is crushed into small particles by a series of crushers After primary crushing with jaw crushers and secondary crushing with gyratory crushers and tertiary crushing with cone or high pressure grinding rolls HPGR , the ore is screened on vibrating screens to size the particlescrushed mineral thickeners Prominer (Shanghai) Mining Crushing in Mineral Processing In mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocksmineral processing crushing of gold

Gold Heap Leaching Process Mineral Processing

【Process Introduction】 Heap leaching (HL) is a flexible and economic mineral processing method, commonly used to extract gold from lowgrade gold ores In this process, ore is firstly crushed to fine particles By spraying leaching solution to the large piles, the goldcontaining solution is leached The most common and notable example of this are precious metal values (gold, silver etc) where the beneficiation process is applied directly on runofmine ores followed by the extraction of gold and in some cases silver as a relatively pure metal within the mineral processing circuit 20 Processing Approach and MethodIntroduction to Mineral Processing or Beneficiation Gold processing Gold processing Mining and concentrating: The nature of the ore deposit determines the mining and mineral processing techniques applied Oxide ore deposits are frequently of such low grade (eg, 3 to 10 parts per million) that extensive mineral processing cannot economically be justified In this case they are merely shattered by explosives and then piled into heaps for Gold processing Mining and concentrating Britannica

Gold Mineral Processing Thesis Topics Cil

Gold Mineral Processing Thesis Topics Cil Gold and silver ore processing and recovery gold and silver ore processing and recovery plants for saleSavona equipment is your source for new, used, and reconditioned ore mineral processing plants of many types and capacity for large primary ore processing, secondary, and tertiary fine material concentrating as well as complete aggregate, recycling Freemilling gold can be further classified into low grade and high grade which helps determine the most economical and optimal gold recovery method Low Grade Low grade freemilling gold deposits contain less than 1 g/t of gold This low grade ore is crushed and heap leached to recover the gold While heap leach recoveries are lower than in Gold Recovery And How To Choose Sepro Mineral requirements of gold mineral processing plants in raigarh Gold Processing Plants AusencoSabodala Gold Project (SARL), Senegal Engineering, Procurement, Construction Management, Commissioning and Performance testing services for the delivery of the 20 Mt/y gold mine processing plant and associated infrastructure, including a 650 person accommodation facility, mine vehicle workshops and 「requirements of gold mineral processing plants in

Mineral Processing SlideShare

Mineral Processing 1 2 2 3 (Ore) 3 4 WHAT CONSTITUTES MINERAL BENEFICIATION? Ore is an aggregate of minerals and contains valuable and gangue minerals The mineral beneficiation involves separation of gangue minerals from ore It has three Tailings Mineral Industry Solution Magnetite is mined in large chunks and is crushed into small particles by a series of crushers After primary crushing with jaw crushers and secondary crushing with gyratory crushers and tertiary crushing with cone or high pressure grinding rolls HPGR , the ore is screened on vibrating screens to size the particlescrushed mineral thickeners Prominer (Shanghai) Crushed stone: natural rock (mostly rock) is crushed and sieved by mining machinery The size of crushed stone is often larger than 475mm, and the surface is rough and angular 2Source comparison Gravel: usually found in deposits containing sand, mainly excavated from sediments in What is the difference between gravel and crushed