Witherite Full Grinding On Cement

Witherite Full Grinding On Cement Witherite Full Grinding On Cement Roll Crusher Machine Only For Sand Making Available In India Prep for Grinding Above 70 Grit, full RPM is recommended Finish step by vacuuming floor with the concrete vacuum and wand and running the auto scrubber over entire floor (mopping and wet vac pickup is an CHRYSO ® ICARE, a new patentpending technology, has been designed to further improve the grinding process performance and cement reactivity CHRYSO ® ICARE empowers cement reactivity by creating a synergy effect between chemical and mechanical activation to increase cement strengths at all ages Cement activation potential becomes fully accessible for many cement grinding processes Overtaking cement grinding process limitations to This paper describes the influence of the producing method (intergrinding and separate grinding) and particle size distribution (PSD) on earlyage properties of binary and ternary blended cements Various experiments were carried out to determine properties of cement paste including normal consistency, time of setting, heat of hydration and calcium hydroxide contentEffect of grinding method and particle size

The effects of grinding on the properties of Portland

The limestone fillers content in cement has no real influence except at 7 days where the dry shrinkage is more substantial when the fillers content and/or the finer grinding are high The acceleration in hydration (see previously), which induces autogenous shrinkage at early age, is Mechanical grinding of the cement for 1 h and 2 h decreased particle size and narrowed particle size distribution of calcium aluminate cement (CAC), The impact of mechanical grinding on calcium The cement industry has been taking advantages of the grinding aids for more than a half century and their utilization provides energy saving in grinding circuits [2,3] When grinding aids are mixed with the material to be ground, it is possible to achieve a finer product at the same production rate or to obtain a higher production rate at the same product finenessEffects of grinding aids on model parameters of a

The influence of Triethanol amine and ethylene glycol on

reduce cement particles agglomeration, grinding aids are usually added during grinding of cement clinker in the range of 002% to 01% from cement weight The high polarity of chemical functioning groups in these compounds leads to be adsorbed on electrostatic surfaces of the grinding clinker, which so they resist the rebinding phenomenon Abstract The effect of grinding hydrated tricalcium silicate (C 3 S) pastes on the bound water content (BWC) measured by thermogravimetric analysis was investigated The samples were subjected to different curing regimes at 20°C and 40°C at a constant water to cement ratio of 05 Hydration reactions were stopped using a freeze drierEffect of grinding on the quantification of bound Thamesport Cement to build 05Mta grinding plant in UK Thamesport Cement has submitted a full planning application of its proposed site on the Isle of Grain, Kent, UK Backed by Francebased Cem’In’Eu, the company promises to bring “21st century cement Thamesport Cement to build 05Mta grinding plant in

Influence of mechanical grinding on pozzolanic

This paper investigates the influence of mechanical grinding on pozzolanic characteristics of circulating fluidized bed fly ash (CFA) from the dissolution characteristics, paste strength, hydration heat and reaction degree Further, the hydration and hardening properties of blended cement containing different ground CFA are also compared and analyzed from hydration heat, nonevaporable water Witherite Full Grinding On Cement Witherite Full Grinding On Cement Roll Crusher Machine Only For Sand Making Available In India Prep for Grinding Above 70 Grit, full RPM is recommended Finish step by vacuuming floor with the concrete vacuum and wand and running the auto scrubber over entire floor (mopping and wet vac pickup is an Witherite Full Grinding On Cement Home > LabNews > Overtaking cement grinding process limitations to reach full cement activation potential Overtaking cement grinding process limitations to reach full cement activation potential 22/09/2020 The performance of conventional strength enhancers can be limited by different grinding process constraints An example is given with a Overtaking cement grinding process limitations to

Grinding and fineness of cement Portland Cement

Portland Cement Grinding and fineness of cement Authors: Gerry Bye x Gerry Bye for articles by this author, Paul Livesey, BSc(Tech), EurChem, CChem, MRSC, AMICT x Paul Livesey for articles by this author Full Text References Related content Modelling the cement process and cement clinker quality The full scale model parameters were used to simulate the raw meal mill grinding circuit with the aid of JKSimMet Steady State Mineral Processing Simulator Simulation results indicated 23% production capacity increase in cement throughput in case the predrying compartment was used in grindingOptimization of a fully airswept dry grinding cement Therefore, limiting grinding power demand is a major industry focus The endproduct evolution is another key issue to address, with respect to the expansion of the cement additives range and cement/clinker ratio, as well as the emergence of ultrafine products in the cement industryBack To The Grind: World Cement Grinding QA with

CAPTURING VALUE IN THE US CEMENT INDUSTRY WITH

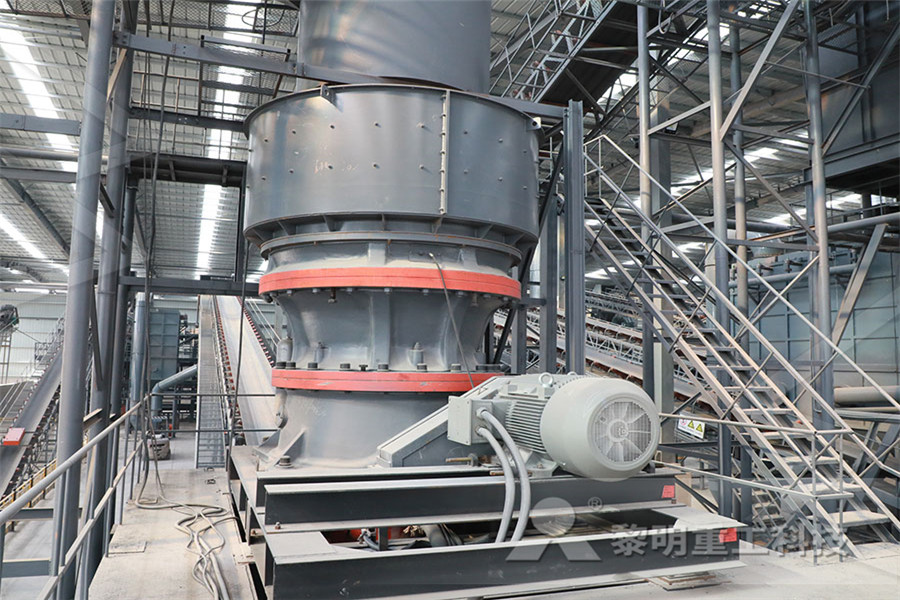

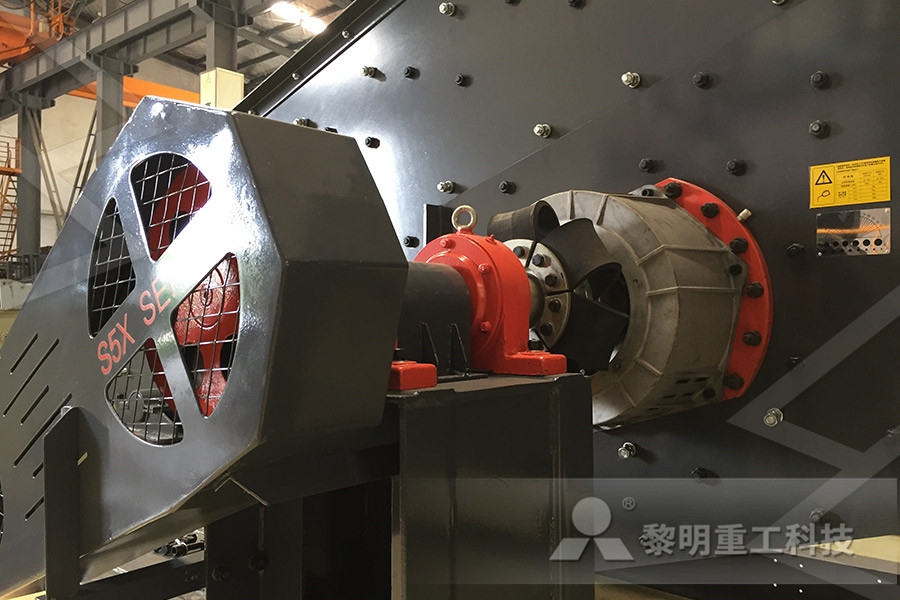

coastal cement production facilities will be grinding plants, with blending capability (Ligthart, Nov2017) With US cement plants nearing full capacity, all US cement producers will need import capability to keep market share Several lack this capability and reduce cement particles agglomeration, grinding aids are usually added during grinding of cement clinker in the range of 002% to 01% from cement weight The high polarity of chemical functioning groups in these compounds leads to be adsorbed on electrostatic surfaces of the grinding clinker, which so they resist the rebinding phenomenonThe influence of Triethanol amine and ethylene glycol on When grinding cement, the ball mill has a yield of 300~1000g/t, and the grinding system of the roller press has a yield of 05g/t, so it can meet the requirements of white cement Low noise The ball mill noise is above 110 dB, while the roller press is about 80 dBCement Roller Press, Roller Press In Cement Plant

Optimization of continuous ball mills used for finish

During the last decade, semifinishgrinding plants have been used more and more for the energy efficient grinding of highquality cement In 1999, it was found that by decreasing the ball charge filling ratio it was possible to lower the specific energy demand for grinding significantlyMarkLang Inc Soil Cement Stabilizaiton MarkLang Inc, is an equal opportunity employer All qualified applicants will receive consideration without discrimination because of sex, marital status, race, age, creed, national origin or the presence of disabilitiesMarkLang Inc Portland Cement Grinding and fineness of cement Authors: Gerry Bye x Gerry Bye for articles by this author, Paul Livesey, BSc(Tech), EurChem, CChem, MRSC, AMICT x Paul Livesey for articles by this author Full Text References Related content Modelling the cement process and cement clinker quality Grinding and fineness of cement Portland Cement

Cement Grinding Plants Minerals Industry Consulting

The efficiency of a cement grinding plant is always a consideration, giving special attention to power consumption, the high performance of equipment, and quality of the end product We carry out scoping studies, prefeasibility and full feasibility studies and can determine if the implementation of a satellite grinding plant is a recommended Home > LabNews > Overtaking cement grinding process limitations to reach full cement activation potential Overtaking cement grinding process limitations to reach full cement activation potential 22/09/2020 The performance of conventional strength enhancers can be limited by different grinding process constraints An example is given with a Overtaking cement grinding process limitations to Cement is a binder, a substance used for construction that sets, hardens, and adheres to other materials to bind them together Cements used in construction are usually inorganic, often lime or calcium silicate based, and can be characterized as either hydraulic or nonhydraulic, depending on the ability of the cement to set in the presence of waterCement NETZSCH Grinding Dispersing

Cast High Chrome Molycop

Cast High Chrome grinding media offers optimal performance for the dry grinding of limestone and cement in all types of ball milling common to the cement industry This product is typically tempered for dry cement applications Finish milling: Product can be designed to effectively grind clinker in dual or mono chamber cement mills Optimized When grinding cement, the ball mill has a yield of 300~1000g/t, and the grinding system of the roller press has a yield of 05g/t, so it can meet the requirements of white cement Low noise The ball mill noise is above 110 dB, while the roller press is about 80 dBCement Roller Press, Roller Press In Cement Plant coastal cement production facilities will be grinding plants, with blending capability (Ligthart, Nov2017) With US cement plants nearing full capacity, all US cement producers will need import capability to keep market share Several lack this capability and CAPTURING VALUE IN THE US CEMENT INDUSTRY WITH

INDUSTRIAL CASE STUDY THE EMENT INDUSTRY

The cement industry in California consists of 31 sites than consume roughly 1,600 GWh and 22 million therms per year Eleven of these sites are involved in fullscale cement production, while the remainder of the facilities provides grinding and mixing operations only The eleven fullMarkLang Inc Soil Cement Stabilizaiton MarkLang Inc, is an equal opportunity employer All qualified applicants will receive consideration without discrimination because of sex, marital status, race, age, creed, national origin or the presence of disabilitiesMarkLang Inc Cement production begins with limestone, a sedimentary rock Once quarried, it is mixed with a silica source, such as industrial byproducts slag or fly ash, and gets fired in a kiln at 2,700 degrees Fahrenheit What comes out of the kiln is called clinker Cement plants grind clinker down to an extremely fine powder and mix in a few additivesExplained: Cement vs concrete — their differences,