machines to process iron ore

Machines to Process Iron Ore Depending on the abundant practical expertise, has develop into one of your most wellknown and processional iron ore processing machine suppliers around the globe Our iron ore processing machine consists of crushing machine, grinding gear and beneficiation machine and so Machines Used To Process Iron Ore Machines Used To Process Iron Ore Mining and Ore Processing Mercury Pollution Estimated Population at Risk Mercury is also extensively used in the gold mining process as an amalgam for separating gold from ore When mercury is combined with gold silt it Learn More; machines used to mine iron oremachines that are used for iron ore bizneshelppl tools used to mine iron ore – Grinding Mill China machines used to mine iron ore Dezzo Equipment is exhibiting various mining machines, mobile crushers etc for machines used to mine iron Mining

machinery and equipment used in the extraction of

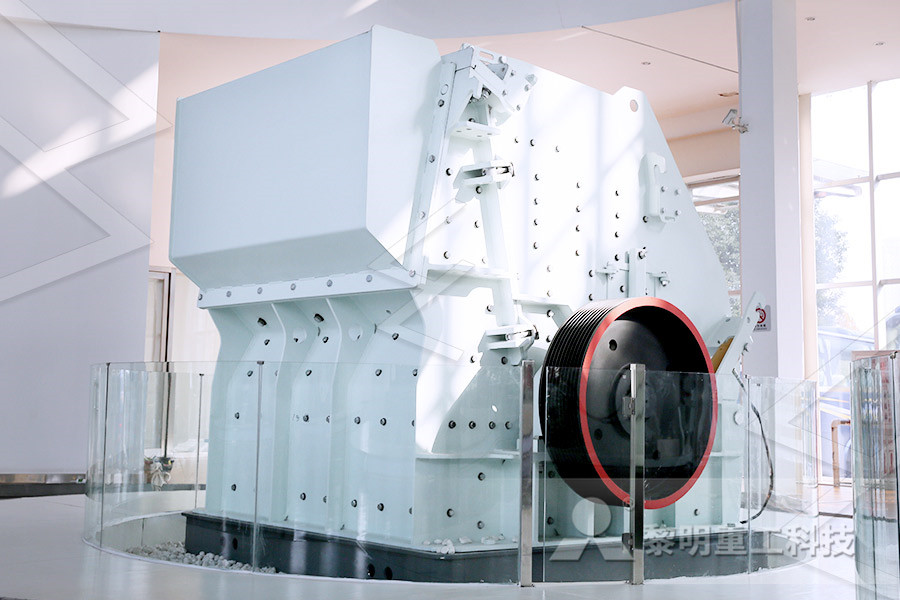

+ Optional Equipment + Ore Crusher + Project; Iron ore extraction process machine Chat Print Posts Related to Iron ore extraction process machine machinery for extraction, separation and processing for quartz and The durability of any gold extraction equipment is very essential because most of the Iron Ore Crusher Machine used in Iron ore beneficiation technology and process 121720; 349 Views; icon 0 Iron ore is one of the important raw materials for the production of pig iron and steel in the iron and steel industry There are many types of iron ore According to the magnetic properties of the ore, it is mainly divided into strong magnetism and weak magnetismIron ore beneficiation technology and process,gravity Iron processing, use of a smelting process to turn the ore into a form from which products can be fashionedIncluded in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a Iron processing Britannica

Macro machines: The biggest and best mining

Wirtgen developed the 4200 SM surface miner in conjunction with iron producer Fortescue Metals Group (FMG) as a highperformance machine suited to the demands of the iron ore mining process The vehicle has a cutting drum unit that is customised for the hard rock conditions prevalent in iron ore Pelletizing Fans Pelletizing is a process that involves mixing very finely ground particles of iron ore fines of size less than 200mesh with additives like bentonite and then shaping them in to oval/spherical lumps of 816mm in diameter by a pelletizer and hardening the balls by firing with a fuelProcess Fans in Iron and Steel Industry This ore is normally rich in iron oxides and vary in color from dark grey, bright yellow and deep purple to rusty red The iron itself is usually found in the form of magnetite (Fe3O4), hematite (Fe2O3), goethite (FeO(OH)), limonite (FeO(OH)n(H2O)) or siderite (FeCO3) The process of mining consists of discovery of an iron ore deposit through Mining of Iron Ores – IspatGuru

Iron ore grinding machines,ball mill for iron ore

Iron ore grinding process Iron ore grinding adopts open circuit process and close circuit process, the ore grinding is mainly composed of the following operations: open circuit process: storage of iron ore, feeding, ore grinding, and delivery of grinded products, close circuit process: storage of iron ore, feeding, ore grinding, classification of iron ore flour mill discharge, delivery of As the iron travels down the molding line, the temperature gradually decreases from about 1,200 to 900 degrees Fahrenheit Temperature at this stage varies based on the size of the casting as well as the molding rate At the end of the mold line, castings enter a shakeout process where the molds are shaken off and the sand is recycled for reuseProcess Iron Castings Pennsylvania iron ore extraction, where the washers were the primary technology in extraction chain Use and tank washers are used as finishing machines because of the special amenability of certain ores to of log washers on the Minnesota Mesabi iron range to process lowgrade hematites and limonites in aMachinery to Match the Materials: Iron Ore Washing in

Iron processing Ores Britannica

Iron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is Iron Mining Process From blasting to crushing to separation – more than 85% of the iron mined in the United States is mined in northeastern Minnesota to make our nation’s steel Blasting Taconite is a very hard rock Using explosives, the taconite is blasted into small pieces The iron ore is separated from the taconite using magnetism Iron Mining Process Minnesota Iron focuses on modeling an iron ore magnetic separation processing plant in Arena discrete event simulation software (Rockwell Automation) A typical iron ore processing plant, with several comminution and separation stages, is considered for simulation The flow sheet of the process is illustrated in Fig 1Discrete Event Simulation of an Iron Ore Milling Process

Offers the Best Iron Ore Processing Plant

The most commonly used crushers and grinding mills in iron ore crushing and grinding process for iron ore mining are jaw crusher, cone crusher, Iron ore is the primary raw material used to make steel Steel is strong, longlasting and costefficient – making it perfect for everything from washing machines to cars, bridges and skyscrapers According to the World Steel Association, steel is the most commonly used alloy in the world Global Iron Ore Rio TintoThe copper mine process is three stages with closedcircuit and washing (with spiral classifier shaker) process, now the amount of mud becomes less, and it changed to three closedcircuit process, this copper mine process can be finally crushing the ore to less than 15mm The equipment used here including lattice screen, vibration screen, jaw Machines Used in Copper Mineral Processing Xinhai

Iron in the Industrial Revolution ThoughtCo

The iron industry began to relocate to coal fields, which usually had iron ore nearby Developments elsewhere also helped to boost iron by stimulating demand, such as the increase in steam engines (which needed iron), which in turn boosted iron innovations as The iron ore processing plant machines up for sale are from the leading sellers and trusted manufacturers who assure outstanding quality and steady performance for a long time These motoroperated iron ore processing plant machines are available in various distinct models and their capacities may vary for eachHigh Precision, Advanced iron ore processing plant As the iron travels down the molding line, the temperature gradually decreases from about 1,200 to 900 degrees Fahrenheit Temperature at this stage varies based on the size of the casting as well as the molding rate At the end of the mold line, castings enter a shakeout process where the molds are shaken off and the sand is recycled for reuseProcess Iron Castings

KOBELCO Pelletizing Process

iron briquettes Sintered ore is made by partially melting and sintering coarse iron ore 1 to 3mm in size into products having a size of 15 to 30mm The sintering process uses the combustion heat of coke breeze (fuel) Pellets are made from iron ore that is finer than that used for sintered ore The ore This series iron ore crusher really supply simpler, higher efficient lower cost machines for clients Vibrating Feeder and Screening Machine Used in Iron Ore Mining Vibrating feeder is the machine used to feed iron ore evenly to iron ore crushing and grinding Offers the Best Iron Ore Processing Plant To make iron from the ore, it is reduced and melted in a blast furnace with coke at over 1300°C The resulting pig iron contains more than 2% carbon and cannot be used for products in this form It is only through the LD process that the pig iron is converted into steel by blowing it Production voestalpine Stahl Donawitz GmbH

Iron Ore Rio Tinto

Iron ore is the primary raw material used to make steel Steel is strong, longlasting and costefficient – making it perfect for everything from washing machines to cars, bridges and skyscrapers According to the World Steel Association, steel is the most commonly used alloy in the world Global Modeling Sintering Process of Iron Ore Jose Adilson de Castro Graduate Program on Metallurgical Engineering Federal Fluminense University Brazil 1 Introduction In this chapter, a methodology for simulating th e sintering process of iron ore is presented In order to study the process parameters and inner phenomena, a mathematical modelModeling Sintering Process of Iron Ore IntechOpenThe copper mine process is three stages with closedcircuit and washing (with spiral classifier shaker) process, now the amount of mud becomes less, and it changed to three closedcircuit process, this copper mine process can be finally crushing the ore to less than 15mm The equipment used here including lattice screen, vibration screen, jaw Machines Used in Copper Mineral Processing Xinhai

Iron in the Industrial Revolution ThoughtCo

The iron industry began to relocate to coal fields, which usually had iron ore nearby Developments elsewhere also helped to boost iron by stimulating demand, such as the increase in steam engines (which needed iron), which in turn boosted iron innovations as Process The modern manufacture of safety pins is completely automatic Specialized machines have been developed to perform multiple steps, replacing many workers and increasing the efficiency of the manufacturing process Over 3 million safety pins can be made by one factory in How safety pin is made material, manufacture,