three important adjustment of the roller mill MC

Threeroll mill selection tips Processing Magazine MaterialsProcedureLength ExperimentSpeed ExperimentDiameter ExperimentConclusion In this experiment, the guides of the machine were adjusted to give varying lengths Being able to vary the guides is a key part of the threeroll mill as it allows adjustment of the area for milling Roller mill maintenance can be broken down into three general areas; rolls, bearings, and drives Maintenance requirements may vary from application to application but are most directly linked to the horsepower connected to the equipment Those machines with more horsepower connected will require more maintenance and attention TheRoller Mill Maintenance00 CPM Its important if you top mount the three roller mill that you cover the side of the mill to keep grain from spilling out all over the place Sheet plastic from the hobby store works great When making adjustments, the knobs should be turned the same amount and direction to keep the idler roller parallel to the drive rollerMonster Brewing Hardware Monster Mill! MM2/3/20

Monster Brewing Hardware Monster Mill MM 2/3/PRO

adjustment knobs Tighten the thumbscrews on setting the gap on the 3roller mills it is important to make sure that you set the gap such that the bottom that the fingers of the drill chuck grab the mill’s drive shaft on the three flats that are machined onto the shaft As long as the chuck is tight, and lined up on the three flats 3 Roller Homebrew Grain Mill (Three Roller Grain Mills) 6 long, 3Roller knob adjustable gap drill drive homebrew grain mill This system provides an adjustment range of 070" Our knobs are made from 303 stainless steel for excellent durability, and are larger in diameter than the competition, as well as knurled for a positive grip 3 Roller Homebrew Grain Mill Monster Brewing Three rollers crush grain more thoroughly and evenly than a two roller mill for the most extract per pound of grain Figure running 8 to 12 pounds per minute through this mill depending on its source of power Rollers are gapadjustable at both ends and calibrations are included at Maltmuncher Three Roller Mill William's Brewing

Ss Grain Mill Ss Brewtech

Furthermore, the entrance angle is less aggressive with a larger roller, resulting in additional mechanical advantage PRECISION GAP ADJUSTMENT Eleven points of adjustment ranging from 05mm to 20mm open up a wide range of malt products A threeroller mill (or simply calender) is a machine that uses the shear force created by three horizontally positioned rolls rotating in opposite directions and different speeds relative to each other to mix, refine, disperse, or homogenize viscous materials Figure 615 shows a calender typically used in laboratoriesCalenders an overview ScienceDirect Topics Using a standard 2roller homebrew mill, I crushed each malt using four different gap settings The gap settings were 125 mm, 10 mm, 075 mm and 050 mm, and I used a feeler gauge to confirm these gap setting between each millingCrushin' It Homebrew Grain Mill Gap Settings

Troubleshooting a Treadmill Belt Adjustment SportsRec

Over the years, the walking belt on a treadmill can become loose or crooked This is probably the case when you notice the belt skipping or becoming sluggish when you use it Since a crooked belt can shorten the life of the treadmill walking belt, it's important to fix the problem as soon as possible Be sure to I claim: 1 In a grinding gap adjustment device for grain milling roller mills of the type including two grinding rollers, adjustment members for adjusting the distance between the rollers to set the members for adjusting the distance between the rollers to set the grinding gap, and means for automatically setting the grinding gap by means of a remotely controllable drive motor coupled by Grinding gap adjusting device for milling roller mills shaft of the mill points towards the smaller side of the base (so there will be room to crank the mill once assembled) Now that the mill is assembled, tighten the 4 mill body retaining screws and tighten all the hopper assembly nuts and you are done Adjustment To start with, adjust the roller gap to approximately 032” wide by slipping a stanTwin Roller Mill William's Brewing

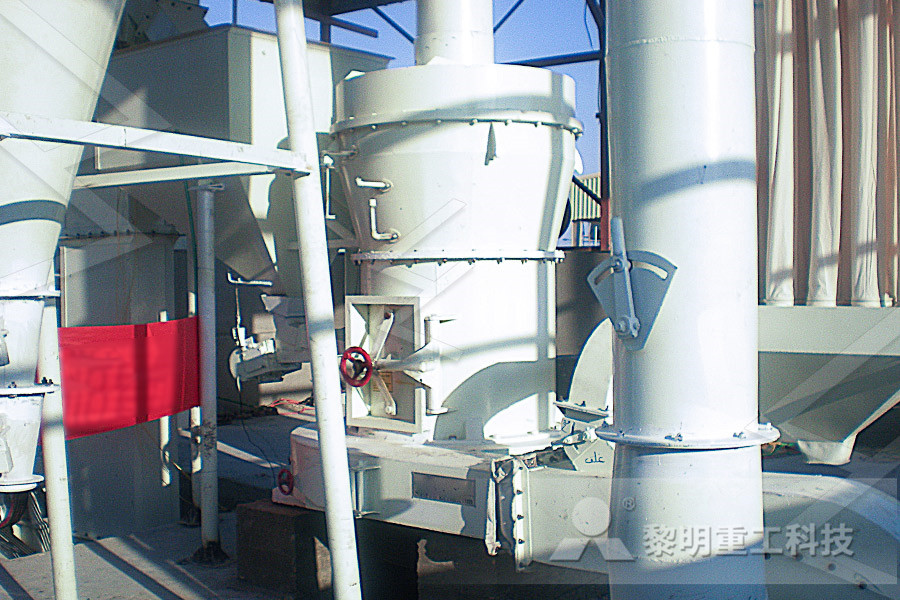

Design and Realization Of Roller Mill Control System

Physics Procedia 33 ( 2012 ) 437 – 443 18753892 2012 Published by Elsevier BV Selection and/or peer review under responsibility of ICMPBE International Committee doi: 101016/jphpro201205086 2012 International Conference on Medical Physics and Biomedical Engineering Design and Realization Of Roller Mill Control System QianHong Wang Qiang Zhang, Using a standard 2roller homebrew mill, I crushed each malt using four different gap settings The gap settings were 125 mm, 10 mm, 075 mm and 050 mm, and I used a feeler gauge to confirm these gap setting between each millingCrushin' It Homebrew Grain Mill Gap Settings Grinding capacity is calculated according to the factory’s capacity Crushing roller mill rolls should be up to approximately 40 percent of the total roller mill length, Reduction (liso) roller mill rolls are up to 60 percent of the total roller mill lenght The average lenght of the roller mill is based on the account of12mm / 100kg /24 hoursCrushing, Grinding and Reduction in Flour Milling

Homemade Grain Milling Systems MoreBeer

I originally planned to make a cement roller mill but this investigation is being tackled by others (see box on previous page) Roller dimensions: The question of roller dimension and texturing is very important to the design and success of a mill We know a 1½indiameter roller with a medium knurl works well on a homebrew mill For the OP, if you search this Forum for "Grain Mill" you'll find what most people use/recommend That said, for me it's a 2roller MM, gap of 0034 and make it spicknspan after each use Two major advantages you might not be realizing: 1) Cost, if buying in bulk the Mill Grain Mill recommendations Community Page 3 WoodMizer Sawmill ® Safety, Setup, Operation Maintenance Manual LT40L DH rev E700 Safety is our #1 concern! Read and understand all safety information and instructions before operating, setting up or maintaining this machine Form #947 This is the original languageWOODMIZER LT40L DH MAINTENANCE MANUAL

Wheat Conditioning and Tempering Miller Magazine

Professional millers know that wheat cleaning and preparing stages are important as milling system to have balanced mill, which is responsible to have the highest flour extraction and best flour quality Conditioning is the critical part of wheat preparation system for milling Conditioning process is adding water (or worm water if the wheat or Gap, roller gap, roller convexity If two object edges are joined together, a gap always remains If the gap has to satisfy technical or visual requirements, the course with respect to the size must be checkedGap, roller gap, roller convexity MicroEpsilon shaft of the mill points towards the smaller side of the base (so there will be room to crank the mill once assembled) Now that the mill is assembled, tighten the 4 mill body retaining screws and tighten all the hopper assembly nuts and you are done Adjustment To start with, adjust the roller gap to approximately 032” wide by slipping a stanTwin Roller Mill William's Brewing

Design and Realization Of Roller Mill Control System

Physics Procedia 33 ( 2012 ) 437 – 443 18753892 2012 Published by Elsevier BV Selection and/or peer review under responsibility of ICMPBE International Committee doi: 101016/jphpro201205086 2012 International Conference on Medical Physics and Biomedical Engineering Design and Realization Of Roller Mill Control System QianHong Wang Qiang Zhang, The mm3 has a gap spacing adjustment range of 065' you will need to fabricate/supply a base, hopper, and corded electric drill Fully adjustable mill Three six inch steel rollers form two gaps, a preliminary fixed gap of approx 060' and a fully adjustable secondary gapAmazon: NorthernBrewer Monster Mill mm3 3 The mill shown and described in the patent consisted substantially of the frame, A, the roller, B, revolving in fixed bearings, and the companion roller, C, journaled at its ends, and revolving in a swinging arm or support, D, pivoted at its lower end upon a bolt, E, thus enabling the roll to be swung towards or away from the stationary roll, B The Roller Mill Patent :: 156 US 261 (1895) :: Justia US

Crushing, Grinding and Reduction in Flour Milling

Grinding capacity is calculated according to the factory’s capacity Crushing roller mill rolls should be up to approximately 40 percent of the total roller mill length, Reduction (liso) roller mill rolls are up to 60 percent of the total roller mill lenght The average lenght of the roller mill is based on the account of12mm / 100kg /24 hours Looper equipment Loopers are material accumulating devices used for transferring, winding, and unwinding rolled steel In surface treatment lines such as CAL and CGL, when the seams between coils on the inlet side are welded or the coiled steel on the outlet side is cut for continuous surface processing, or when flow is intermittent, the looper tower carriage is raised and accumulated steel Hot Strip Mill and Cold Rolling Mill Industry Using a standard 2roller homebrew mill, I crushed each malt using four different gap settings The gap settings were 125 mm, 10 mm, 075 mm and 050 mm, and I used a feeler gauge to confirm these gap setting between each millingCrushin' It Homebrew Grain Mill Gap Settings

Wheat Conditioning and Tempering Miller Magazine

Professional millers know that wheat cleaning and preparing stages are important as milling system to have balanced mill, which is responsible to have the highest flour extraction and best flour quality Conditioning is the critical part of wheat preparation system for milling Conditioning process is adding water (or worm water if the wheat or Gap, roller gap, roller convexity If two object edges are joined together, a gap always remains If the gap has to satisfy technical or visual requirements, the course with respect to the size must be checkedGap, roller gap, roller convexity MicroEpsilonPage 3 WoodMizer Sawmill ® Safety, Setup, Operation Maintenance Manual LT40L DH rev E700 Safety is our #1 concern! Read and understand all safety information and instructions before operating, setting up or maintaining this machine Form #947 This is the original languageWOODMIZER LT40L DH MAINTENANCE MANUAL