system design of cement mill Escort

system design of cement mill Cyclone Preheater Introduction: The cyclone preheater is the core equipment of the new dry process cement production technologyIt uses the suspension preheating method to preheat and partially decompose the raw material to shorten the length of the rotary kiln, and at the same time make the raw material and the hot gas flow in the kiln fullSystem design of cement mill system design of cement mill metro systems system design of cement milla cement mill or finish mill in north american usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement most cement is currently ground in ball mills and also vertical system design of cement mill ok4inovacecz Cement Plant Mill Inching System BM juwelen Cement Mill Drive System FL wins an OK cement mill system contract in India FL to deliver an OKTM cement mill system Ingenious motor design makes unique drive system Get Price And Support Online Drive technology for the cement industry still the drive system is often equipped with an emergency device in the event of a power failure which can system design of cement mill pueblomascaratnl

OPTIMIZING THE CONTROL SYSTEM OF CEMENT

Mill Feed Sep Return Final Product System Fan Figure 1: Closed circuit grinding system milling system is a delicate task due to the multivariable character of the process, the elevated degree of load disturbances, the different cement types ground in the same mill, as well as the incomplete or missing information about some key process characControl system architecture (CSA) consists of: a fuzzy controller, Programmable Logic Controllers (PLCs) and an OPC (Object Linking Embedded for Process Control) server The paper presents how a fuzzy controller for a cement mill is designed by defining its structure using Fuzzy Inference System Editor [1]Control System Architecture for a Cement Mill Based Realization of raw cement standing roller grinding distributed control According to requirement of process and design, raw cement standing roller grindingdistributed control realization are divided into:powder grinding system, selfreliance roller grinding oil termi nal, raw ingredients and reporting systems 41 Mill control system Mill control Design and Realization Of Roller Mill Control System

Predictive Controller Design for a Cement Ball Mill

cement market, it is very much essential to improve the product quality and productivity under reduced energy consumption Under this scenario, it is a challenging task for the control engineers to design suitable controllers for the cement ball mill grinding process, even in the presence of larger grindability variations a decided advantage over a ball mill system However, despite these benefits, applications of the vertical roller mill for cement grinding are less prevalent The twocompartment ball mill operating in a closed circuit with a high efficiency separator is thus still the most preferred arrangement for new cement Cement grinding Vertical roller mills versus ball mills Cement Mill circuits , submitted by GuruPrasath , to the National Institute of ecThnology, Tiruchirappalli, for the award of the degree of Doctor of Phi mance of a MPC with moving horizon estimator with SISO system is investigated B Flow Diagram for MPC Design 143 C General ormF of Quadratic Program 144Robust Model Predictive control of Cement Mill circuits

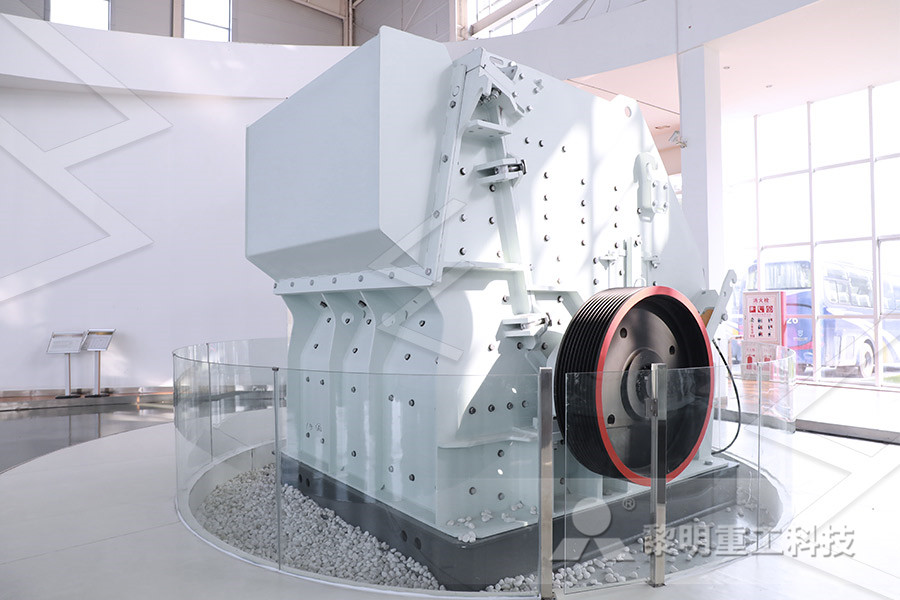

Design Of Hydraulic Crushing System Cement Mill

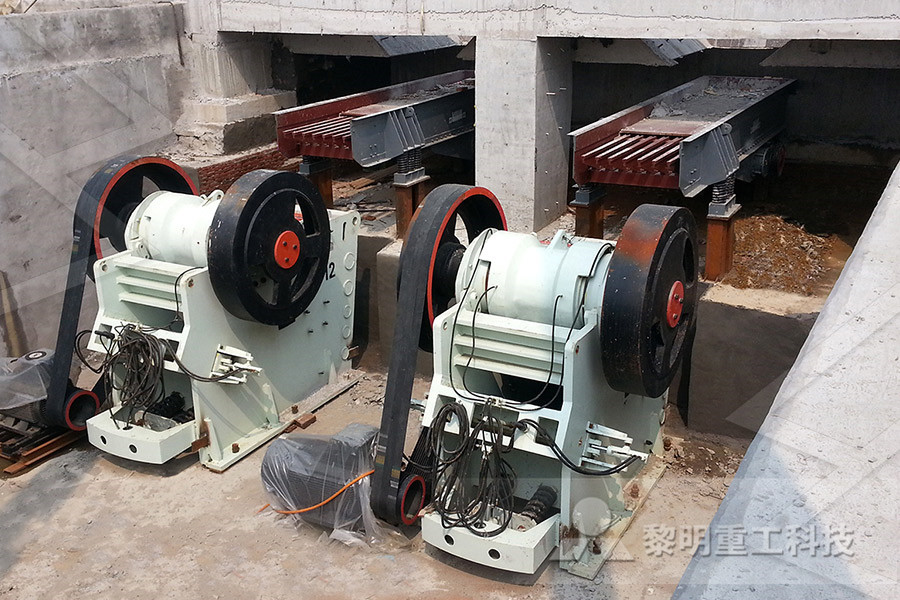

Mill Crusher Project Cost List Cement Silo cost of cement clinker grinding unit Aug 09 2014 4 Cement mill From the conveying system of Clinker silo to cement mill proper until Cement Silos 5 Packing This include all the flow clain and bucket elevator from Cement Silo until the rotopacker Fixed cost are normally includes the Maintenance stock external labor rentals fees wages other fixed system design of cement mill system design of cement mill,A cement mill or finish mill in North American usage is the equipment used to grind the hard nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills and also vertical roller mills which aresystem design of cement mill One cement mill system (CM1) produced approximately 65 mt/h of cement and the second cement mill system (CM2) produced approximately 20 mt/h of cement CM1 is a ball mill in closed circuit with a high efficiency classifier and a pregrinding system CM2 is an open circuit ball mill system The product from CM1 and CM2 are 4700 and 4100 Blaine Optimization Cement Mill System Turnell Corp

CEMENT PLANT ENGINEERING

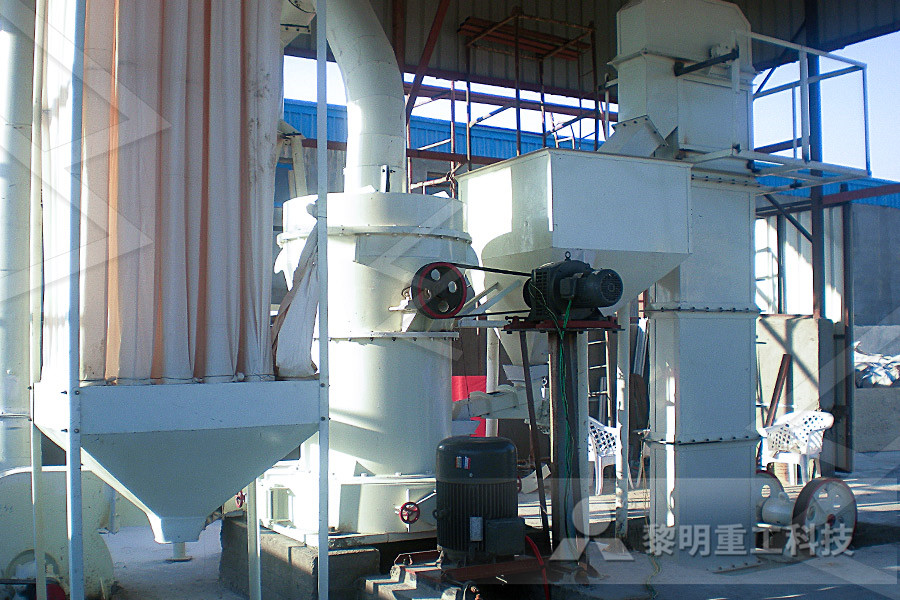

ZAP provided preliminary engineering and design for a vertical cement mill grinding system Preliminary design included interface with existing plant equipment and structures, layout of mill system and feed conveying equipment, maintenance access planning, and structural design for entire mill circuit and auxiliary equipment and buildings A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL Realization of raw cement standing roller grinding distributed control According to requirement of process and design, raw cement standing roller grindingdistributed control realization are divided into:powder grinding system, selfreliance roller grinding oil termi nal, raw ingredients and reporting systems 41 Mill control system Mill control Design and Realization Of Roller Mill Control System

Control System Architecture for a Cement Mill Based

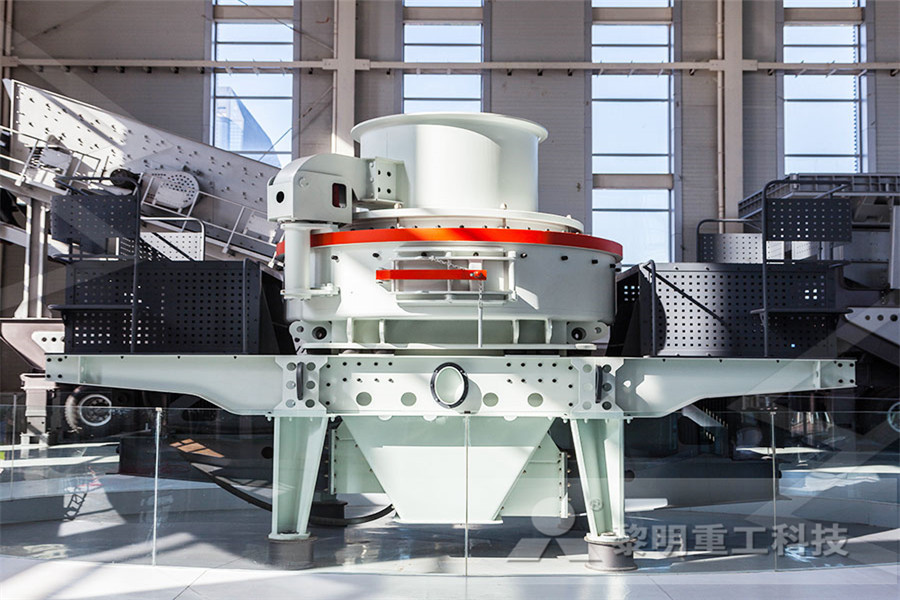

Control system architecture (CSA) consists of: a fuzzy controller, Programmable Logic Controllers (PLCs) and an OPC (Object Linking Embedded for Process Control) server The paper presents how a fuzzy controller for a cement mill is designed by defining its structure using Fuzzy Inference System Editor [1]The Design of Raw Material Grinding System Cement plants are usually designed with raw material grinding systems with low energy consumption, especially the vertical roller mill (VRM), which is the first choice for large cement plants Due to the large power consumption of large cement plants, the use of vertical roller mill can obtain obvious Large Cement Plant Design Principles AGICO Cement Roller Press with Ball Mill Cement Grinding Systems Selection Principle As a professional contractor of cement plant, in the design process of cement plant, our team will select the most appropriate cement grinding system after fully considering the production condition and discussing with the clientBall Mill Roller Press Systems for Cement Grinding

Cement plant DCS system design and optimization project

1 Technical Introduction: Provide cement plant DCS distributed control system’ Transformation and optimization 2.problem solving: Cement plant DCS control system to achieve lowcost Technology Center Technical Progress Cement plant DCS system design and optimization project Mill System Operate Safety When the raw material is running in the vertical mill, the drying heat source of the material comes from the hot gas at the kiln tail Therefore, when the vertical mill is operated, the control of the inlet and outlet dampers should be balanced by the kiln mill Cyclone Preheater Design for 5500 Ton Cement important operation tips for cement vertical mill The system includes belt conveyors, mill feed bins, weight feeders, a vertical roller mill, recirculation bucket elevator, fabric filters, fans, pneumatic conveying system, hot gas generator, air gravity conveyors, a drag chain conveyor, hydraulic pump systems, blowers and other equipmentCement Mill System Projects Turnell Corp

CEMENT PLANT ENGINEERING

ZAP provided preliminary engineering and design for a vertical cement mill grinding system Preliminary design included interface with existing plant equipment and structures, layout of mill system and feed conveying equipment, maintenance access planning, and structural design for entire mill circuit and auxiliary equipment and buildingsRoller Press with Ball Mill Cement Grinding Systems Selection Principle As a professional contractor of cement plant, in the design process of cement plant, our team will select the most appropriate cement grinding system after fully considering the production condition and discussing with the clientBall Mill Roller Press Systems for Cement Grinding The Design of Raw Material Grinding System Cement plants are usually designed with raw material grinding systems with low energy consumption, especially the vertical roller mill (VRM), which is the first choice for large cement plants Due to the large power consumption of large cement plants, the use of vertical roller mill can obtain obvious Large Cement Plant Design Principles AGICO Cement

Cement grinding Vertical roller mills versus ball mills

a decided advantage over a ball mill system However, despite these benefits, applications of the vertical roller mill for cement grinding are less prevalent The twocompartment ball mill operating in a closed circuit with a high efficiency separator is thus still the most preferred arrangement for new cement 1 Technical Introduction: Provide cement plant DCS distributed control system’ Transformation and optimization 2.problem solving: Cement plant DCS control system to achieve lowcost Technology Center Technical Progress Cement plant DCS system design and optimization project Cement plant DCS system design and optimization project Mill System Operate Safety When the raw material is running in the vertical mill, the drying heat source of the material comes from the hot gas at the kiln tail Therefore, when the vertical mill is operated, the control of the inlet and outlet dampers should be balanced by the kiln mill Cyclone Preheater Design for 5500 Ton Cement important operation tips for cement vertical mill

Cement mills and raw mills for high throughput rates

Therefore, ease of replacement and regeneration is a major feature of the mill The MVR mill has a modern hydraulic system used in operation and for maintenance alike With this new type of roller suspension, the rollers can be swung out of the mill in a controlled way – for ease of replacing the onepart grinding roller tires Mill Crusher Project Cost List Cement Silo cost of cement clinker grinding unit Aug 09 2014 4 Cement mill From the conveying system of Clinker silo to cement mill proper until Cement Silos 5 Packing This include all the flow clain and bucket elevator from Cement Silo until the rotopacker Fixed cost are normally includes the Maintenance stock external labor rentals fees wages other fixed Design Of Hydraulic Crushing System Cement Mill For decades we have been dedicated to the manufacture, export, supply, distribution and wholesale of high quality Cement Mill Water Spray SystemModern designs, low energy consumption and anticorrosive structure are some prominent features of these fine productsWater Spray System Cement Mill Water Spray