DEVELOPMENT OF A WATER TREATMENT PLANT FOR A

Keywords: Wastewater purification plant, rollingmill train, water treatment 1 Introduction In the rollingmill train the “billet” used as raw material is heated to 1080 ºC using natural gas in a glory hole with a radiant dome and three temperature control zones: preheating, heating and equalisation DAAAM INTERNATIONAL SCIENTIFIC BOOK 2009 pp 965976 CHAPTER 94 WATER TREATMENT PLANT FOR A ROLLING MILL TRAIN GOICOECHEA, I MARTINEZ, S Abstract: Water treatment plants consist in systems where water is treated and subjected to diverse processes based on the intended industrial use of the waterWATER TREATMENT PLANT FOR A ROLLING MILL TRAINJatindra Engineering Corporation is a leading enterprise in the field of design and manufacturing of Water Treatment Lines TMT Quenching Boxes that come utilised in production of Rebars in Rolling Mill plants Premiumquality raw material are sourced Hot Rolling Mills Water Treatment Lines TMT Quenching

Water treatment plant for a rollingmill train Free

Water Treatment Plant for a RollingMill Train, Chapter 94 in DAAAM International Scientific Book 2009, pp 965976, B Katalinic (Ed), Published by DAAAM International, ISBN 9783698, ISSN 17269687, Vienna, Austria The noncontact water circuit, for instance, isn't subjected to all the treatment steps necessary for the contact water circuit The noncontact water circuit, with a 6,470 m³/hr volumetric flowrate, is for cooling the EAF, ladle furnace, continuous casting molds, ladle furnace, reheat furnace and rolling mill fume dedusting plantWater treatment plant for meltshop and rolling mill in Cooling Water Treatment Reclaim wastewater from the cooling water Kwangyang #4 Hot Rolling Mill Plant Coolant System Capa(m³/hr) 11,520 Completion date 201208 Main Process Auto Strainer + Coolant Pump 2’nd Stainless CCM Slab Revamping Facilities Capa(m³/hr) 3,300 Completion date 201312 Main Process Cooling Tower + Heat Water Treatment Specialist – Coway EnTech

Development of a water treatment plant for a rollingmill

* Second phase for the production of wire rolls The water has the following function in the lamination process: All rollingmill trains must have a water treatment plant for cooling purposes and to eliminate the particles which the water picks up in the lamination process Cold Rolling Wastewater Cold Roll Mill Wastewater These revisions may result in a reduction in the allowable limits for discharges from the continuous caster water treatment facilities It is expected that these changes will reduce the discharge limits of metals such as nickel, chromium, lead, and zinc, and could well require additional Steel and Manufacturing Water and Wastewater Treatment The water system treats and supplies 35,000 m3/hr of water for all these systems, as well as the makeup water system, which treats the water originating from several deep wells, a purging system and the waste treatment of the cold emulsions mill The water treatment plant has been designed to reduce fresh water requirements, to keep Big River Steel Water Treatment Plant Phase I Russula

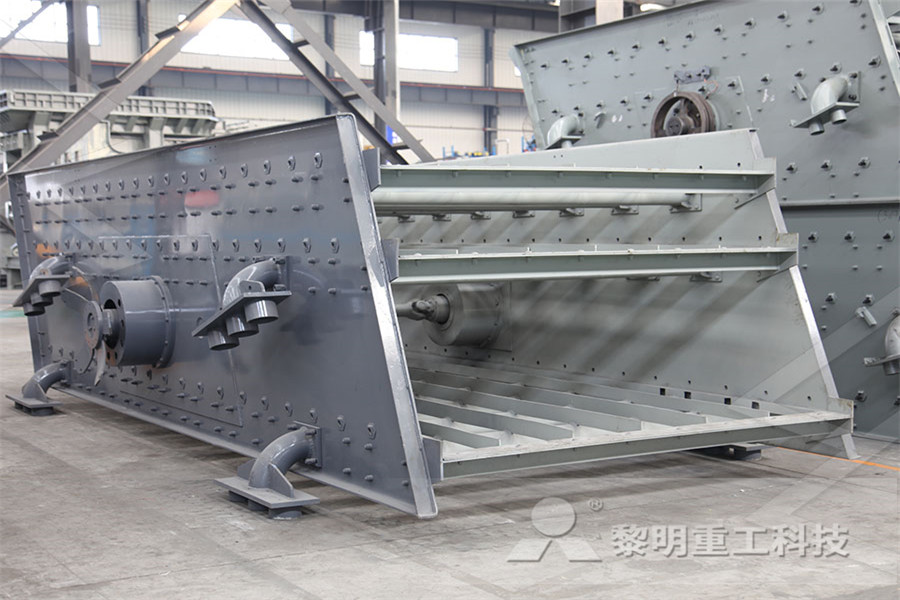

Water descaling unit for rolling mill ENCE

Water descaling unit for rolling mill In its program, Production and Engineering Company ENCE GmbH (ЭНЦЕ ГмбХ) highlights the most significant metallurgical equipment; this equipment complies with the highest international quality standards and may be Water Treatment Plant for a RollingMill Train, Chapter 94 in DAAAM International Scientific Book 2009, pp 965976, B Katalinic (Ed), Published by DAAAM International, ISBN 9783698, ISSN 17269687, Vienna, AustriaWater treatment plant for a rollingmill train Free Cold Rolling Wastewater Cold Roll Mill Wastewater These revisions may result in a reduction in the allowable limits for discharges from the continuous caster water treatment facilities It is expected that these changes will reduce the discharge limits of metals such as nickel, chromium, lead, and zinc, and could well require additional Steel and Manufacturing Water and Wastewater Treatment

Water Treatment Plants BBC SteelTech

> Rolling Mills > Reheating Furnaces > Rolling Stands > Shears Saws > Cooling Beds > Finishing Facilities > Gearboxes > Robots Tilters > Guides > Mill Ancillaries > Meltshops > Electric Arc Furnaces > Ladle Furnaces > Continuous Casting Machines > Ladles > Scrap Buckets > Preheaters > Other Meltshop Equipment > Auxiliary Plants > Water In order to satisfy the water quality requirements of the pipe mill, MET will design and build four water treatment facilities for its pipe rolling, steelmaking, pipe finishing mill and entire plant wastewater treatment station individually The heat load of the circulating water will be removed by various types of cooling towersPipe Dream WWD Water Wastes DigestPrimetals Technologies supplied the complete rolling line, which included the foundation design and auxiliary equipment that comprised rollshop equipment, the watertreatment system, the compressedair plant, cranes, ventilation and airconditioning, as well as the firedetection and extinguishing facilitiesSUPERIOR MILL PERFORMANCE Primetals Technologies

Siemens to supply water treatment plant for Slovakia Steel

On August 23, Austriabased plantmaker Siemens VAI announced that it has received an order from Slovakia Steel Mills (SSM) in Strážské, Slovenia, to supply a water treatment plant for its new steelworks The plant will treat the water used for direct and indirect cooling and is scheduled to come on stream by the end of 2010 The order is worth some ten million euro, Siemens VAI said 23 Intensive Cooling Equipment Close to Mill: SuperCR Controlled rolling is a technology in which strength is increased by applying plastic deformation in the nonFig 1 Layout of online accelerated cooling and heattreatment facilities in West Japan Works (Fukuyama)Development of ThermoMechanical Control Process Super Steel Forgings Exporter of Heat Treatment Facilities, Hot Rolling Steel Melting from Kolkata, West Bengal, IndiaExporter of Heat Treatment Facilities Hot Rolling by

ThyssenKrupp Announces Completion Of Water Treatment

ThyssenKrupp Stainless USA and ThyssenKrupp Steel USA today announced the completion of the process water and wastewater treatment systems at its new facilities in Calvert, Alabama The systems were designed and built by NA Water Systems, a Veolia Water Solutions Technologies (VWS) company located near Pittsburgh, PAThe Cold Rolling Mill incorporates the following unique facilities: Continuous Pickling and Tandem Cold Mill for absolute scalefree surface and unidirectional rolling through 5stand 6hi mill (first time in India) Universal Crown, AGC and ASC (auto gauge and shape control) for Technology Tata Steelium > Rolling Mills > Reheating Furnaces > Rolling Stands > Shears Saws > Cooling Beds > Finishing Facilities > Gearboxes > Robots Tilters > Guides > Mill Ancillaries > Meltshops > Electric Arc Furnaces > Ladle Furnaces > Continuous Casting Machines > Ladles > Scrap Buckets > Preheaters > Other Meltshop Equipment > Auxiliary Plants > Water Water Treatment Plants BBC SteelTech

Development of ThermoMechanical Control Process

23 Intensive Cooling Equipment Close to Mill: SuperCR Controlled rolling is a technology in which strength is increased by applying plastic deformation in the nonFig 1 Layout of online accelerated cooling and heattreatment facilities in West Japan Works (Fukuyama)Santanu Chakraborty, in Treatise on Process Metallurgy: Industrial Processes, 2014 65 Rolling Mills The rolling mill facilities were designed to meet the production requirement of Table 1The rolling mills complex was proposed to include a light and medium merchant mill with breakdown group of stands for rolling blooms into billets and an intermediate inline heat compensating furnace; a Rolling Mill an overview ScienceDirect TopicsPrimetals Technologies supplied the complete rolling line, which included the foundation design and auxiliary equipment that comprised rollshop equipment, the watertreatment system, the compressedair plant, cranes, ventilation and airconditioning, as well as the firedetection and extinguishing facilitiesSUPERIOR MILL PERFORMANCE Primetals Technologies

FACILITIES – BSSL

• 510 mm dia Roughing Mill • 380 mm dia Intermediate Mill • 320 mm dia Finishing Mill • Automatic Cooling Bed arrangement • Intermediate induction heating for size 1225 Sizes Range: Round / RCS Bar sizes : 12 to 62 mm dia for Alloy Steel Stainless Steel 12 to 25 mm dia straight length for Valve steelThe Cold Rolling Mill incorporates the following unique facilities: Continuous Pickling and Tandem Cold Mill for absolute scalefree surface and unidirectional rolling through 5stand 6hi mill (first time in India) Universal Crown, AGC and ASC (auto gauge and shape control) for Technology Tata SteeliumSuper Steel Forgings Exporter of Heat Treatment Facilities, Hot Rolling Steel Melting from Kolkata, West Bengal, IndiaExporter of Heat Treatment Facilities Hot Rolling by

Products KOBE STEEL, LTD

Water Treatment Facilities Full lineup! A leading manufacturer in the field of water treatment, Kobelco EcoSolutions offers a full lineup of water treatment products, including water and sewage treatment facilities, industrial water and wastewater treatment facilities, sludge treatment facilities and pure/ultrapure water production facilities distribution stations, various utility facilities, water treatment and distribution system, etc The list of facilities for the proposed expansion would be as follows: Sl No Unit Facility 1 Hot Strip Mill 16 MTPA (existing) augmented to 24 MTPA 2 Cold Rolling Mill Bright Annealing HAPL Pickling Line 20 Hi Mill JINDAL UNITED STEEL LIMITED 16 MTPA TO 24 MTPA ThyssenKrupp Stainless USA and ThyssenKrupp Steel USA announced the completion of the process water and wastewater treatment systems at its new facilities in Calvert, Ala The systems were designed and built by NA Water Systems, a Veolia Water Solutions Technologies (VWS) company located near PittsburghThyssenKrupp completes water treatment facilities for new