balling of fine particles Prominer (Shanghai) Mining

balling of fine particles Dec 20 2019 0183 32 The presence of fine particles can be nonmelted power or spatters which were sintered on/near the track surface without melting due to their existence in the heataffected zone With the exception of the tracks produced at laser scanning speed of 014 m/s extensive balling was observed along the track edgUnderstanding Pellets and Pellet Plant Operations Pelletizing is an agglomeration process which converts very fine grained iron ore into balls of a certain diameterballing of fine particles mojursuspl balling of fine particles Wembley Primary School A Look at the Process of Pelletizing Iron Ore for Steel Pelletizing or balling carried out through either a disc pelletizer or rotary drum is a key part of efficiently and sustainably producing steel from iron ore fines of varying sources FEECO is a leader in feasibility testing custom disc pelletizers and balling drums and aftermarket balling of iron ore balling formation FStechniek

Ball Milling an overview ScienceDirect Topics

Ball mills, like the three roll machine, are a common occurrence in industry, for the production of fine particles During the ball milling process, there are two factors that contribute to the exfoliation The main factor contributing is the shear force applied by the balls Using only shear force, one can produce large graphene flakesThis is a review of hydrophobic agglomeration methods to be used for fine particles in water suspensions The hydrophobic interaction as a consequence of the hydrogenbonding energy of water molecules, in the vicinity of hydrophobic particles, is discussed The pattern of the growth of agglomerates is essentially determined by hydrodynamic forcesHydrophobic Agglomeration of Fine Particles Clean inner surface of balling drum and moisten very lightly It may be desirable to precoat inner surface of drum with a thin layer of material being agglomerated Start rotation of drum and add small quantities of ore in 50 gram amounts to the drum With a water spray bottle, ensure a fine adequate wetting of the ore surfaceAgglomeration of Particles 911 Metallurgist

SIZE SEPARATION PHARMA NOTES

These produce a current of air as shown by the arrows The fine particles are picked up and are carried into space, where air velocity is sufficiently reduced The fine particles are dropped and ultimately collected at an outlet meant for fine particles The heavy particles which fall downward are removed at an outlet meant for heavy particlesParticles come in a wide range of sizes Fabric filter with different structure shows different filtration performances on fine particle In the paper, two types of filter media structure, ie nonwoven structure and membrane structure are compared and studied It can be seen that the pressure drop of membrane filter is apparently much higher than that of nonwoven structure for it owns a Effect of Filter Media Structure on Fine Particle Hunan Key Laboratory of Intelligent Robot Technology in Electronic Manufacturing With continuous rotation of the disc, fine particles are gathered and formed into larger pellets in the stable area, finally falling out of the disc as green pellets As the disc pelletizer is the main equipment for powder pelletizing and can be used for InquiryDisc pelletizer for fine powder particles/ pelletizer

Effect of Bimodal Powder Mixture on Powder Packing

form necking between particles compared to irregularly shaped particles (Cima et al, 1992) Many models and experimental results have shown that high packing density can be achieved when the volume fraction of fine powder is between 0204 (Zheng et al, 1995) In this1 Introduction Fine particles entail processing problems in various Granulation, or balling, is the process of forming and different areas of the industry Especially in the mining aggregates by agglomerating particles with the sprinkling of and metallurgical industry, the ore fines have been the cause a binding liquid while they are revolved Effect of binder and drum speed on hematitic fines balling Balling can occur with any hydratable clay Clays particles can adhere to each other or metal surfaces, given the right water and solids ratio Therefore, reduction of adhesion and/or balling can be achieved by controlling hydration and/or solids concentration Bit balling is more of a problem when using Water Based Mud When invert emulsions Bit Balling Definition, Causes, Prevention, Treatment

Disc pelletizer for fine powder particles/ pelletizer

Low cost balling disc pelletizer,organic fertilizer disc pelletizer machine Introduction of balling disc pelletizer The balling disc pelletizer is arc and its granulating ratio is over 93% Balling disc pelletizer is main equipment which makes powder into ball shape, widely applied in cement industry, iron and steel industry and InquiryThis is a review of hydrophobic agglomeration methods to be used for fine particles in water suspensions The hydrophobic interaction as a consequence of the hydrogenbonding energy of water molecules, in the vicinity of hydrophobic particles, is discussed The pattern of the growth of agglomerates is essentially determined by hydrodynamic forcesHydrophobic Agglomeration of Fine Particles SpringerLink Balling technologies Bonding mechanisms Evolution of binders for iron ore pelletizing This cohesive tension of fine particles due to water is called neutral tension Neutral tension, however,is notsufficient tokeep cohesivegrainsasdenseasiron mineralsFurthermore, whenIron Ore Pelletizing Process: An Overview

KOBELCO Pelletizing Process

13 Balling process In this process, balling equipment produces green balls from the prewetted material prepared in the previous process The green balls are produced either by a balling drum (Fig 5), or by a balling pan (disc) (Fig 6) Both of the units utilize centrifugal force to form the fine materials into spheroids The greenBit Balling The strong, thin edges of each Pheno Seal® particle cut away at formation buildup on bits and stabilizers like a knife blade Pheno Seal® also contains approximately 7 times more particles per pound than nut plugPheno Seal for lost circulation, bit balling, pipe and Paste particles are ejected from deposit due to rapid heating of vapor phase process (paste spatter) it was the only one that we've had solder balling issues with all the other ones (matte finish) were fine The solder mask can have an important impact on the quality Solder Balling Splash After Reflow

Effect of Bimodal Powder Mixture on Powder Packing

form necking between particles compared to irregularly shaped particles (Cima et al, 1992) Many models and experimental results have shown that high packing density can be achieved when the volume fraction of fine powder is between 0204 (Zheng et al, 1995) In this Balling can occur with any hydratable clay Clays particles can adhere to each other or metal surfaces, given the right water and solids ratio Therefore, reduction of adhesion and/or balling can be achieved by controlling hydration and/or solids concentration Bit balling is more of a problem when using Water Based Mud When invert emulsions Bit Balling Definition, Causes, Prevention, Treatment The fragments or fine particles can be formed by particle size reduction (fig 1) FIG 1: PELLET GROWTH MECHANISM Balling: It is the Pelletization process in which pellets are formed by a continuous rolling and tumbling motion in pans, discs, drums or mixtures The process consists of conversion of finely divided particles in to spherical PELLETIZATION TECHNOLOGY: A QUICK REVIEW

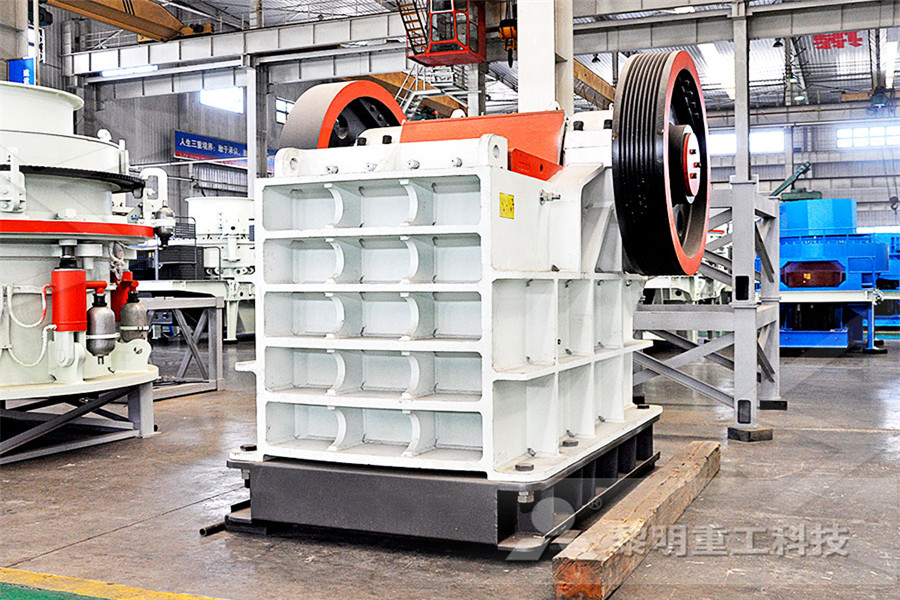

Design of Pelletizing Machine (Balling Disc)

1) High balling rate 2) Big roundness intensity of particles 3) Visual operation and easy for maintenance They are of different kinds and forms ranging from its sizes, shapes, method of operation (manual or automatic), capacity, function, etc A Types of Pelletizing Machine 1) Pelletizing machine (Balling disc): Balling disc machine 13 Balling process In this process, balling equipment produces green balls from the prewetted material prepared in the previous process The green balls are produced either by a balling drum (Fig 5), or by a balling pan (disc) (Fig 6) Both of the units utilize centrifugal force to form the fine materials into spheroids The greenKOBELCO Pelletizing Process Clean inner surface of balling drum and moisten very lightly It may be desirable to precoat inner surface of drum with a thin layer of material being agglomerated Start rotation of drum and add small quantities of ore in 50 gram amounts to the drum With a water spray bottle, ensure a fine adequate wetting of the ore surfaceAgglomeration of Particles 911 Metallurgist

ผลการค้นหาคำว่า "balling" จาก

(english) "Fine particles of limestone (flux) and iron ore are difficult to handle and transport because of dusting and decomposition, so the powdery material usually is processed into larger pieces The raw material's properties determine the technique that is used by mills Disc balling granulator is suitable for mixing material pelletizing equipment with nutrient [5] It has the following advantages: (1) High balling rate (2) Big roundness intensity of particles (3) Visual operation and easy for maintenance They are of different kinds and forms ranging from its sizes, shapes, method of operation (manual orWCECS 2012, October 2426, 2012, San Francisco, USA Bit Balling The strong, thin edges of each Pheno Seal® particle cut away at formation buildup on bits and stabilizers like a knife blade Pheno Seal® also contains approximately 7 times more particles per pound than nut plugPheno Seal for lost circulation, bit balling, pipe and

OpenSLS RepRap

Open SLS is a selective laser sintering project under active development in Dr Jordan Miller's Physiologic Systems and Advanced Materials Laboratory at Rice University Recently, our lab published our work using OpenSLS for freeform fabrication using nylon and polycaprolactone You can find the full scientific paper at PLOS ONEYou can find Rice's press release on the project here