Cement grinding Vertical roller mills versus ball mills

cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materialsCement grinding Vertical roller mills versus ball mills cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grindingcement grinding mill pdf Felona A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

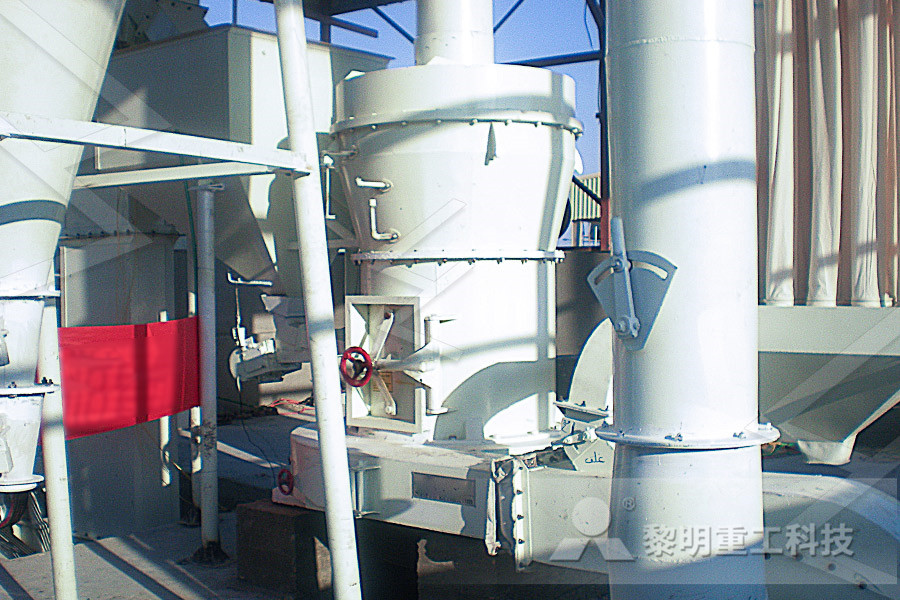

PFEIFFER MILLS FOR THE CEMENT INDUSTRY

7 // Almost any plant for the grinding of cement raw material is a combination of machines specially adapted to the particular physical properties of the material to be ground As a result, our plants work efficiently without any trouble » Highly efficient grinding, drying, and separating in one unit » Outstanding production capacities exceeding 1,400 t/h in one single mill Improved Cement Quality and Grinding Efficiency by Means of Closed Mill Circuit Modeling (December 2007) Gleb Gennadievich Mejeoumov, BS, Ivanovo State Power University, Russia; MS, Ivanovo State Power University, Russia Chair of Advisory Committee: Dr Dan Zollinger Grinding of clinker is the last and most energyconsuming stage of the cementIMPROVED CEMENT QUALITY AND GRINDING typically generates ~ 25 kcal of heat per kg cement ground o Mill temperature could rise to 140 ˚C and causes gypsum to dehydrate produces “false set” in cement, as well as “media coating” which impairs grinding efficiency o typically, ~ 08 m³ of cooling air is required to remove the heat Energy consideration in cement grindingEnergy consideration in cement grinding

FOR CEMENT RAW MATERIAL Loesche

1928 The first springloaded airswept grinding mill in the world, constructed by the original company Curt v Grueber MaschinenbauAnstalt, Teltow near Berlin, is launched onto the market under the name Loesche mill and has 2 grinding rollers It already has all the essential features of modern airswept vertical grinding mills built today The cement mill grinding circuit resembles to some extent grinding circuits used in the mineral industry Model based control technologies for such grinding circuits in the mineral processing industries have been surveyed by Pomerleau et al (2000), Hodouin et al Soft Constrained MPC Applied to an Industrial Cement Recently, the vertical roller mill having great grinding performance is widely applied to the raw material grinding process However, tube mill, which has about 30% poor grinding performance as power consumption, has been still used many existing cement plant The improvement of this tube mill grinding system is highly expected DescriptionsVertical roller mill for raw Application p rocess materials

The cement mill

Cement manufacturing brief description of a cement mill Cement clinker is usually ground using a ball mill This is essentially a large rotating drum containing grinding media normally steel balls As the drum rotates, the motion of the balls crushes the clinker cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding Over the last three decades the vertical roller mill has become the preferred mill for grinding of raw materialsCement grinding Vertical roller mills versus ball mills A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side 31 System Description Mill Rated capacity 150 t/h OPC at PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

cement mill grinding theory pdf alptrittch

cement grinding mill pdf cement mill grinding theory pdf italy Cement grinding Vertical roller mills versus ball mills cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding Increasing Output Of Cement Grinding In Ball MillCase Study 8 Three rows of static air distribution guide vanes are installed with Cage bars have 15°radial position No wear was found at the cage, outlet head and air intake spiral Gap of outer cage wheel sealing = 25 – 35 mm Gap of inner cage wheel sealing = 10 – 30 mm INCREASING OUTPUT OF CEMENT GRINDING IN BALL Recently, the vertical roller mill having great grinding performance is widely applied to the raw material grinding process However, tube mill, which has about 30% poor grinding performance as power consumption, has been still used many existing cement plant The improvement of this tube mill grinding system is highly expected DescriptionsVertical roller mill for raw Application p rocess materials

raw grinding mill cement industry pdf

OK™ mill The most reliable and efficient mill for raw and has supplied the global cement industry with leading Vertical Roller Mill (VRM) designs for raw, fuel and cement grinding for several decades The OK™ mill has been ’s standard cement VRM since 1993 Since its introduction, the OK mill has proven to be the most efficient cementget 1928 The first springloaded airswept grinding mill in the world, constructed by the original company Curt v Grueber MaschinenbauAnstalt, Teltow near Berlin, is launched onto the market under the name Loesche mill and has 2 grinding rollers It already has all the essential features of modern airswept vertical grinding mills built todayFOR CEMENT RAW MATERIAL Loesche The cement mill grinding circuit resembles to some extent grinding circuits used in the mineral industry Model based control technologies for such grinding circuits in the mineral processing industries have been surveyed by Pomerleau et al (2000), Hodouin et al Soft Constrained MPC Applied to an Industrial Cement

cement grinding ball mill design pdf

Cement grinding Vertical roller mills versus ball mills today is the most used mill for cement grinding Over the last three decades the vertical roller mill has become the preferred mill for grinding Grinding Mill Cement Pdf Cement grinding Vertical roller mills versus ball mills cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grinding Over the last three decades the vertical Grinding Mill Cement Pdf schroniskogoldapplCement grinding Vertical roller mills versus ball mills cement industry the ball mill was really an epochmaking breakthrough as for almost 80 years it was the predominant mill for grinding of raw materials and coal, and still today is the most used mill for cement grindingcement grinding mill pdf Felona

Raw grinding and finish milling circuits and

Raw grinding and finish milling circuits and evaluation of their efficiencies, Equipment description and nomenclature, Comminution theory, Cement grinding efficiency, Operational considerations, Microsoft Word 2017 Mill Grinding Course Content Author: 1928 The first springloaded airswept grinding mill in the world, constructed by the original company Curt v Grueber MaschinenbauAnstalt, Teltow near Berlin, is launched onto the market under the name Loesche mill and has 2 grinding rollers It already has all the essential features of modern airswept vertical grinding mills built todayFOR CEMENT RAW MATERIAL Loesche Recently, the vertical roller mill having great grinding performance is widely applied to the raw material grinding process However, tube mill, which has about 30% poor grinding performance as power consumption, has been still used many existing cement plant The improvement of this tube mill grinding system is highly expected DescriptionsVertical roller mill for raw Application p rocess materials

CEMENT Gebr Pfeiffer

newly developed MVR mill for cement grinding have been installed The ordered MVR 5600 C4 has a grinding table diameter of 56 m and roller diameters of 283 m A MultiDrive® with four modules of 1650 kW each has been chosen as the drive system The warranted output rate for PortlandPozzolana Cement (PPC) with 30% fly ash content is 320 t/h at Denmark (trade named Cemax Mill) Horomill is suitable for grinding raw meal, cement and minerals, whereas Cemax Mill is mainly for cement grinding The mill can be used for pregrinding and finish grinding This millsystem claims to have advantages of ball mill, roller mill and roller press in terms of reliability and energy savingsModern Processing Techniques to minimize cost in Ball mill with Central Drive Mill length Mil l diame te r M il l di amet er 5 3 2 3 2 1 3 5 6 6 4 4 Ball mill with Sid e Driv 1 Inlet 2 Outlet casing 3 Slide shoe bearing 4 Main gearbox 5 Mill motor 6 Auxiliary drive 1 3 Ball mill for cement grinding 3 Cement grinding – taking on the tough tasks Cement ball mills have to achieve the desired cement mill drives seminar pdf vierenmetzorgnl

cement mill technical data pdf files

cement mill technical data files Cement mill technical data pdf files cement plant ball mill design data crushing equipment is designed to achieve maximum productivity and high reduction ratio from large primary jaw 247 online new design of cement mill vernalcoin Read more Cement Mill Cement Grinding Mills Material Handled 585 – 620# raw material yields 1 BBL cement (376#) or average ratio 166 : 1 Aerial view of typical cement plant This plant now houses three 9½’ x 25′, an 8½’ x 7′, three 8½’ x 6′ and one 9½’ x 9′ Grate Discharge Ball Mills and one 9½’ x 12′ Open End Cement Rod MillCement Grinding 911 Metallurgistraw mill manpower cement plant filetype pdf 18 Views The is the professional mining equipments manufacturer in the world, located in China,India, along with » التفاصيلraw mill of cement plant pdf