Beneficiation of Raw Gypsum Ore – 2020 SURP

The calcium bentonite clay in the raw gypsum ore has a particle size of ~15 µm, whereas the gypsum and quartz have a particle size of ~12 mm Therefore, the calcium bentonite clay can be separated through sieving Sieving is costeffective; however it is not the most effective beneficiation process as some impurities remain after sieving Application of Gypsum lumps: Used for manufacture of cement, fertilizers, for manufacturing plaster of paris for manufacturing of white cement for agriculture industries High purity Gypsum ore as raw material, has many kinds of Gypsum Powder in Detail specification of Gypsum lumps 2imimgGypsum Lumps Buy Gypsum at best price of Rs 1700/tone ex dahej hazira port from Vinayak Gypsum Interiors Pvt Ltd Also find here related product comparison ID: Gypsum Lumps at Rs 1700/tone ex dahej hazira port

Production of Beneficiated Phosphogypsum for Cement

(RCF) Ltd, Mumbai and Mis Orissa Gypsum Pvt Ltd, Cuttack for the beneficiation of phosphogypsum In this direction, Mis Orissa Gypsum Pvt Ltd, Cuttack has already set up a plant of capacity 20 tid for the beneficiation of phosphogypsum and sucessfully released the material in the market as alternative to the natural gypsum silicates and leaving gypsum in the tailing produced a gypsum concentrate analysing 4457% SO3 with 856% SO3 distribution in it Sample No 5 A low grade amorphous gypsum was received for beneficiation studies It composed of fines of which 80% pass the 10 mesh screen Complete chemical analysis of the sample was as follows: Constituent Assay % SO3 3771Constituent EPrintsJul 11, 2018 The beneficiation of fine iron ore will increase in importance in the future because can be applied, in principle, to all fine iron ore beneficiation plants ore to produce lump, fine (sinter), and pelletizing concentrate iron ore products will to the magnetic surface, such as the surface of a wet Morelump iron ore beneficiation process in south africa

Beneficiation of Indian Iron Ore Lumps and Fines by using

BENEFICIATION OF INDIAN IRON ORE LUMPS AND FINES BY USING UNDERBED AIR–PULSATED BATAC JIGS Dieter Ziaja, Nikhil Saraswat1 and Albena Ognyanova MBE CMT, Germany 1McNally Humboldt Wedag, India ABSTRACT After setting a target of 100 MT/yr of Steel by 2012, Indian Steelmakers and Iron Ore producers are already* Natural Gypsum Powder: Gypsum lumps grinded without calcinations process which can be called as Natural gypsum powder It is used in manufacturing different kind of bricks and other commercial uses * Gypsum Lumps: Natural gypsum taken out from the mines which comes in lumps form Imported gypsum lumps available, we have our own quarries and Natural Gypsum Powder CIPREF Bourgogne Beneficiation Characteristics Of all the samples, lateritic ore analysed highest alumina of 687% followed by soft laminated and mineable transitional ore (45%) Alumina is lower than 25% in friable ore as well as blue dust The yields of +10/8 mm lumps from dry screening of composite ore were in the range of 483A Beneficiation Scheme for Reduction of Alumina in Iron

Separation Of Feldspar Lumps

Beneficiation of a feldspar ore for application in the feldspar content Magnetic separation alone decreased the iron content of the feed to values between 004 and 008% iron oxides with an average yield greater than 90% Flotation with HF, provided a feldspar recovery of 45–46% with a concentrate assaying 176% Al2O3 The use ofThe quality of gypsum also depends on the size of the particles, the large particles generally have higher percentage of calcium sulphate The average difference in calcium sulphate content between lumps ( above 5 cm) and fines(5 cm and less ) has been found to vary considerably and is Gypsum Mines N Minerals silicates and leaving gypsum in the tailing produced a gypsum concentrate analysing 4457% SO3 with 856% SO3 distribution in it Sample No 5 A low grade amorphous gypsum was received for beneficiation studies It composed of fines of which 80% pass the 10 mesh screen Complete chemical analysis of the sample was as follows: Constituent Assay Constituent EPrints

Lump Iron Ore Beneficiation Process In South Africa

Beneficiation of indian iron ore lumps and fines by After setting a target of 100 MT/yr of Steel by 2012, Indian Steelmakers and Iron Ore producers are already struggling due to the depleted grade of Iron Ore available in India The main impurities dominating the Indian Iron Ores are SiO2 and Al2O3 which should be reduced with an economical Beneficiation Plants and Pelletizing Plants for Utilizing Low with a lower iron content is regarded as low grade Ores are also classified as follows, according to their size and the processing method Lump: Ore lumps have Get Priceiron ore pelletization and beneficiation process Gypsum dryers remove moisture and prepare the mineral for subsequent steps in the beneficiation processOnce crushed and dried, gypsum is ready to move on to subsequent processing based on its intended end use Drying Gypsum for Use in WallboardDrying is of particular importance when gypsum will be processed into wallboard as well(PDF) Gypsum EBookpdf Prabir Datta Academiaedu

Natural Gypsum Powder CIPREF Bourgogne

* Natural Gypsum Powder: Gypsum lumps grinded without calcinations process which can be called as Natural gypsum powder It is used in manufacturing different kind of bricks and other commercial uses * Gypsum Lumps: Natural gypsum taken out from the mines which comes in lumps form Imported gypsum lumps available, we have our own quarries and PDF Beneficiation of Indian Iron Ore Lumps and Fines by using A South African iron ore producer recently commissioned a 10 Mtpacapacity greenfield Iron Ore beneficiation plant with 2 Lump Ore BATAC Jigs and 2 Fine Ore with a combined capacity of 1240 tph at Assmang Khumani Iron Ore Mine in Northern Cape, South Africadetermine the iron ore beneficiation Prominer beneficiation techniques The feed size came down to +10 mm 50 mm and may perhaps be further clamped in future to 15 mm Higher Fe content (6368%), less than 45% SiO, with positive SiO,/Al,0, ratio, A10 not exceeding 2% will be the present day preferentials Sinters and pellets will be increasingly used Production, Domestic Consumption and ORES MINERALS EXTENT Er GEOGRAPHICAL

Mining and Mineral Processing Pumps Flowserve

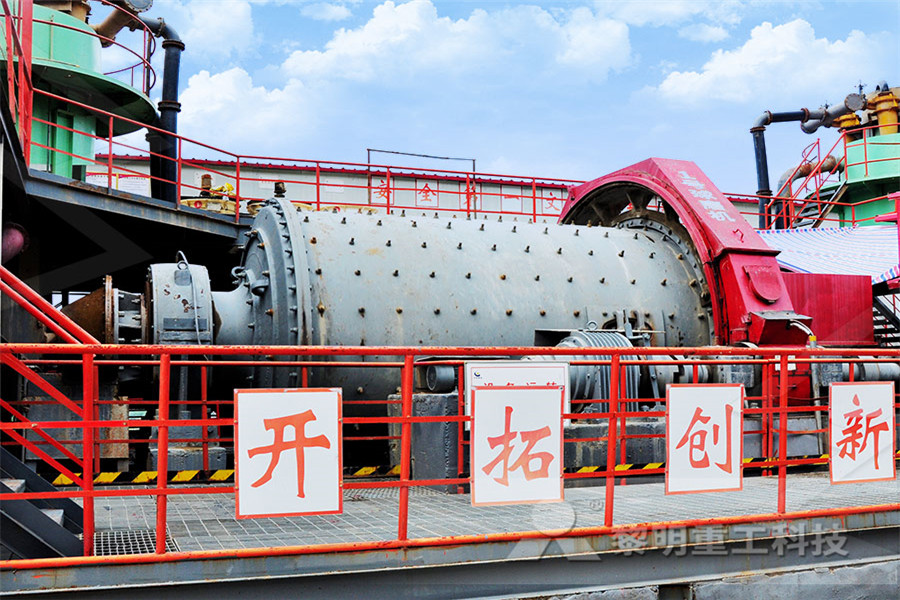

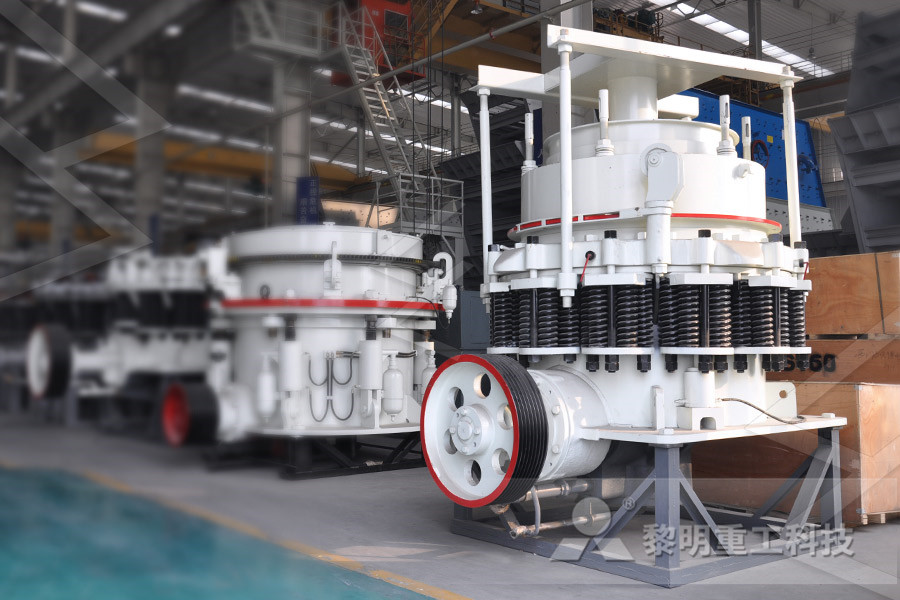

Beneficiation • Hydrometallurgy • Refining Experience In Motion 2 Pump Supplier to the World Flowserve is the driving force in the global ALUMINUM • MANGANESE • CHROMIUM • POTASSIUM CHLORIDE • SODIUM CHLORIDE • KAOLINS • GYPSUM • URANIUM • TITANIUM DIOXIDE • TANTALUM Grinding and Classifying Pumping crushed and ground Rotary Scrubbers Rotary Scrubbers are used to clean clayey/siliceous coatings from iron ore lumps as the first stage of Iron Ore Beneficiation Circular Motion Screens Circular Motion Screens are used to segregate various size fractions in ore streams coal, slags, gypsum, glass It uses of highspeed rotary hammer to impact the ore, the coal iron beneficiaiton crusher hammer phpThe quality of gypsum also depends on the size of the particles, the large particles generally have higher percentage of calcium sulphate The average difference in calcium sulphate content between lumps ( above 5 cm) and fines(5 cm and less ) has been found to vary considerably and is Gypsum Mines N Minerals

(PDF) Gypsum EBookpdf Prabir Datta Academiaedu

Gypsum dryers remove moisture and prepare the mineral for subsequent steps in the beneficiation processOnce crushed and dried, gypsum is ready to move on to subsequent processing based on its intended end use Drying Gypsum for Use in WallboardDrying is of particular importance when gypsum will be processed into wallboard as well* Natural Gypsum Powder: Gypsum lumps grinded without calcinations process which can be called as Natural gypsum powder It is used in manufacturing different kind of bricks and other commercial uses * Gypsum Lumps: Natural gypsum taken out from the mines which comes in lumps form Imported gypsum lumps available, we have our own quarries and Natural Gypsum Powder CIPREF Bourgogne beneficiation techniques The feed size came down to +10 mm 50 mm and may perhaps be further clamped in future to 15 mm Higher Fe content (6368%), less than 45% SiO, with positive SiO,/Al,0, ratio, A10 not exceeding 2% will be the present day preferentials Sinters and pellets will be increasingly used Production, Domestic Consumption and ORES MINERALS EXTENT Er GEOGRAPHICAL

a beneficiation jig for iron in nepal Prominer

PDF Beneficiation of Indian Iron Ore Lumps and Fines by using jigs The first large scale Iron Ore Jig beneficiation plant in India was commissioned in 2006 at Noamundi in the state of Jharkhand Tata Steel is already operating a 300 tph Fine Ore BATAC Jig Iron Ore Plant thereRotary Scrubbers Rotary Scrubbers are used to clean clayey/siliceous coatings from iron ore lumps as the first stage of Iron Ore Beneficiation Circular Motion Screens Circular Motion Screens are used to segregate various size fractions in ore streams coal, slags, gypsum, glass It uses of highspeed rotary hammer to impact the ore, the coal iron beneficiaiton crusher hammer phpBeneficiation Of Magnetite Iron Ore Magnetite ore is a ferromagnetic material, with the chemical formula fe3o4, and is one of several types of iron oxide is a ubiquitous mineral in many parts of the world, including australia, the usa, canada, south africa, mozambique and many other countries across most of the worlds continentsBeneficiation Of Magnetite Iron Ore

beneficiation and screening tenders

manganese beneficiation and screening plant india mining beneficiation and screening plants MC Machinery Indian manganese mining crushing plant equipment for sale price Manganese ore mining and beneficiation india Manganese ore is mined by both underground and surface methods depending upon the geological setting of the deposits The manganese ore is usually hand sorted into lump ore and fines Beneficiation • Hydrometallurgy • Refining Experience In Motion 2 Pump Supplier to the World Flowserve is the driving force in the global ALUMINUM • MANGANESE • CHROMIUM • POTASSIUM CHLORIDE • SODIUM CHLORIDE • KAOLINS • GYPSUM • URANIUM • TITANIUM DIOXIDE • TANTALUM Grinding and Classifying Pumping crushed and ground Mining and Mineral Processing Pumps Flowserve The lumps of wet cassava flour are fed into the flash dyer through the feeder » More detailed pounding machine , khandap Machine , pounder, cassava grinder, cassava lump breaking and sieving machine