Iron Mining Process Minnesota Iron

The iron ore is separated from the taconite using magnetism The remaining rock is waste material and is dumped into tailings basins The taconite powder with the iron in it is called concentrate Pellets The concentrate (the wet taconite powder) is rolled with MINING AND PROCESSING: Iron ore mining can be broadly divided into two categories namely 1) manual mining which is employed in small mines and 2) mechanized mining is suitable for large iron ore mines Manual mining method is normally limited to float ores and small mines Mining of reef ore is also being done manually on a small scaleIron Ore Mining Techniques Metal Extraction Polymetallic magnetic iron ore mine mining process Polymetallic magnetic iron ore mine is often separated by the combined process of weak magnetic separation and flotation method, that is, recovering the iron ore mine by the weak magnetic separation method and recovering the sulfide or apatite by the flotation methodBrief Introduction on Iron Ore Mines Mining Process

Iron Ore Processing Prominer (Shanghai) Mining

Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron ore The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state It consists of several distinct steps The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent, location and value of the ore bodyMining of Iron Ores – IspatGuru When the material exits the mill, the iron ore is classified using cyclones or vibrating screens that separate fine and large particles The large particles are diverted back into the crusher and the fine particles will undergo a spiral gravity separation processThe Six Main Steps of Iron Ore Processing Multotec

Iron Ore,Production Process of Iron Ore,Iron Ore

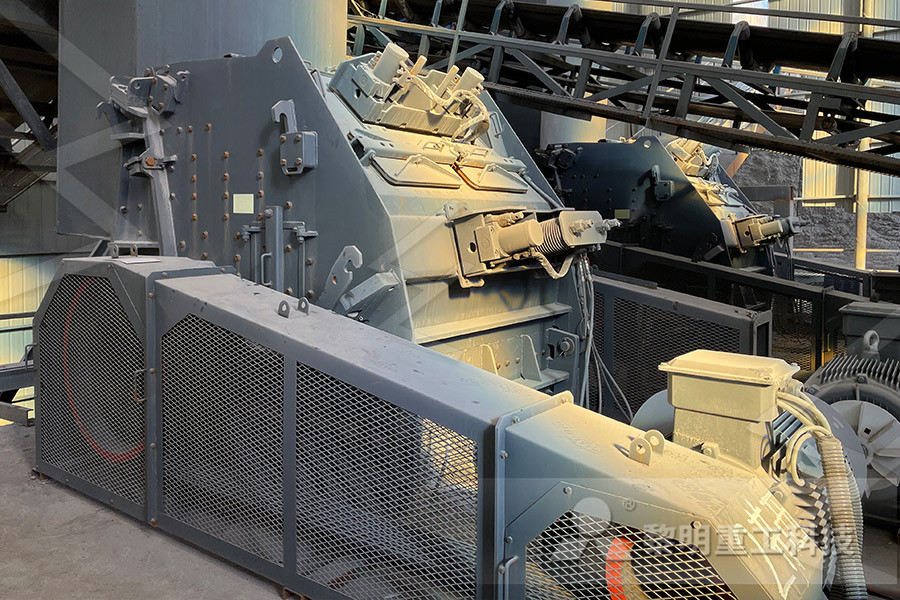

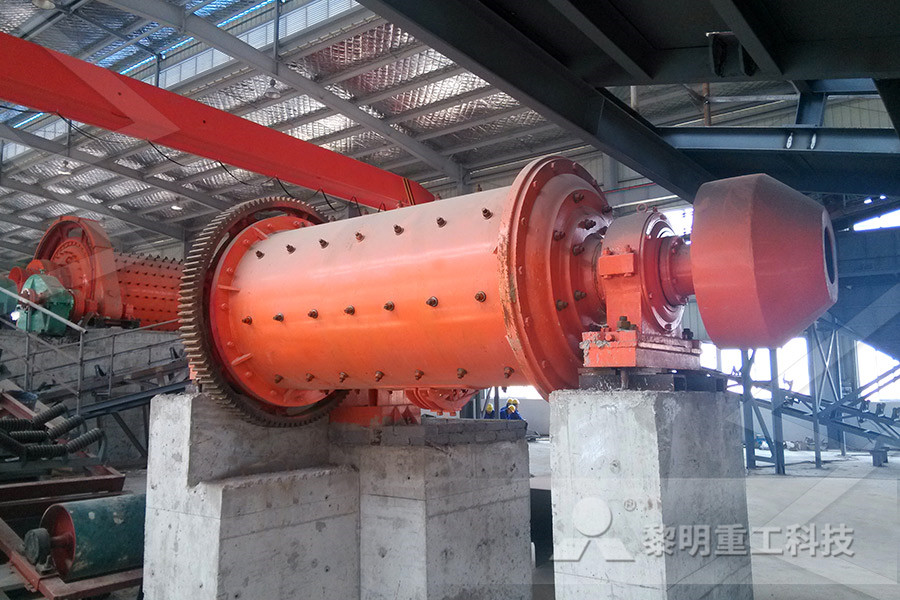

Production Process of Iron Ore Generally, the processing of iron ore needs several processing stages, including crushing, grinding, ore beneficiation, concentrating, drying, etc The equipments for iron ore beneficiation is consisted of Jaw Crusher, Ball The process of mining lowgrade iron ore, or taconite, requires massive resources Heavy industrial mining equipment, expansive mines, and a skilled labor pool are all required Some of the equipment includes diamondbit rotary drills, hydraulic shovels and loaders, waterwagons, production trucks and heavy duty conveyorsIron Ore Mining and Processing where there are long distances between the pits and process plants Process Processing of the ore ranges from simple crushing and screening to a standard size, through to processes that beneficiate or upgrade the quality of the iron ore products This is Iron Ore production in the Pilbara Rio Tinto

Iron Ore Mining, Processing Engineering Ausenco

Our innovative solutions in iron ore have resulted in increased efficiencies in production and achieved highly successful outcomes for our clients To read more, click on the related case studies Paul has 25+ years of diverse experience in the mining and Iron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreIron Ore Processing Prominer (Shanghai) Mining Iron ore mining process Crushing equipment: 1Primary crusher(30mm):Jaw crusher 2Secondary crusher( 10mm):Cone crusher Grinding equipment: Wet ball mill Concentrate dressing: Magnetic separator, classifier, thickener, reverse flotation machineIron ore mining process and iron ore mining

Mining of Iron Ores – IspatGuru

The process of mining consists of discovery of an iron ore deposit through extraction of iron ore and finally to returning the land to its natural state It consists of several distinct steps The first is discovery of the iron ore deposit which is carried out through prospecting or exploration to find and then define the extent, location and When the iron ore is extracted from the mine, it must undergo several processing stages Six steps to process iron ore 1 Screening We recommend that you begin by screening the iron ore to separate fine particles below the crusher’s CSS before the crushing stage A static screen is The Six Main Steps of Iron Ore Processing Multotec Iron ore is an important raw material for iron and steel production enterprises After crushing, grinding, magnetic separation, gravity concentration etc, gradually we can get iron from natural minerals (iron ore) It is the mineral aggregates that contain iron or iron compounds which can be used economically Production Process of Iron Ore Iron Ore,Production Process of Iron Ore,Iron Ore

Iron Ore production in the Pilbara Rio Tinto

Activities involved in finding, mining and processing iron ore at our Pilbara operations have been simplified in the following diagram Rio Tinto operates 11 iron ore mines in the Pilbara and the specific sequence of activities varies from mine to mine Excellence in planning, scheduling and quality control are fundamental to the processOur innovative solutions in iron ore have resulted in increased efficiencies in production and achieved highly successful outcomes for our clients To read more, click on the related case studies Paul has 25+ years of diverse experience in the mining and minerals industry from plant operations to Iron Ore Mining, Processing Engineering Ausenco The ore may be easily beneficiated by a process know as wetmagnetic separation this process has been employed for many decades in North America With OneSteel further rationalising its operations with the emergence of Arrium Mining, a dedicated exporter of iron ore, and supplier of iron ore to OneSteel's integrated steelworks at Whyalla Iron Ore Department for Energy and Mining

Iron processing Ores Britannica

Iron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is Iron processing, use of a smelting process to turn the ore into a form from which products can be fashionedIncluded in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties It constitutes 5 percent by weight of the Earth’s crust, and it is the Iron processing BritannicaIron ore is the key raw material for steel production enterprises Generally, iron ore with a grade of less than 50% needs to be processed before smelting and utilization After crushing, grinding, magnetic separation, flotation, and gravity separation, etc, iron is gradually selected from the natural iron oreIron Ore Processing Prominer (Shanghai) Mining

Iron Ore Mining and Processing

The process of mining lowgrade iron ore, or taconite, requires massive resources Heavy industrial mining equipment, expansive mines, and a skilled labor pool are all required Some of the equipment includes diamondbit rotary drills, hydraulic shovels and loaders, waterwagons, production trucks and heavy duty conveyors The extraction of iron ore involves surface (openpit) or underground mining techniques (please refer to Chapter 7 (Stace, 2015) on Iron Ore Extraction Techniques) The LCA boundary used in this study is shown in Figure 204The mining method selected depends on a variety of factors, including the nature and location of the deposit and the size, depth, and grade of the depositLife cycle assessment of iron ore mining and Iron ore is an important raw material for iron and steel production enterprises After crushing, grinding, magnetic separation, gravity concentration etc, gradually we can get iron from natural minerals (iron ore) It is the mineral aggregates that contain iron or iron compounds which can be used economically Production Process of Iron Ore Iron Ore,Production Process of Iron Ore,Iron Ore

Iron Ore Mining, Processing Engineering Ausenco

Our innovative solutions in iron ore have resulted in increased efficiencies in production and achieved highly successful outcomes for our clients To read more, click on the related case studies Paul has 25+ years of diverse experience in the mining and minerals industry from plant operations to The process of mining lowgrade iron ore requires massive resources Heavy industrial mining equipment, expansive mines, and a skilled labor pool are all required The iron ore processing flowsheet is consists of two processes:Dry Processing and Wet ProcessingIron Ore Processing Flowsheet grinderprocess IRON ORE MINING VIDEOS Iron ores are rocks and mineral deposits from which clanging iron can be reasonably extracted The ores are generally prosperous in iron oxides and fluctuate in color ranging from dark grey, bright yellow, deep purple, to even rusty redIron ores Mining Videos,Iron ores mining process

Iron processing Ores Britannica

Iron processing Iron processing Ores: Iron ores occur in igneous, metamorphic (transformed), or sedimentary rocks in a variety of geologic environments Most are sedimentary, but many have been changed by weathering, and so their precise origin is difficult to determine The most widely distributed ironbearing minerals are oxides, and iron ores consist mainly of hematite (Fe2O3), which is At the end of the openpit mining process in large metal mines, the mining model must change from openpit mining to underground mining, but the mutual interference between the two mining models leads to poor production safety conditions and difficulties in production convergence during the transition period To solve these technical problems of poor production safety conditions and Opencast to underground iron ore mining method Australia possesses the world’s largestknown iron ore reserves with around 50 billion tonnes available to be unearthed, and many of the most productive iron ore miners have based their operations in this country Here, NS Energy profiles the top five iron ore producing countries in the world, based on their mining output in 2020Top five iron ore producing companies in 2020 by