crushing machinery maintenance 」

maintenance of jaw crusher equipment should use a qualified parts and the right tools Use the lubricant recommended instructions to report to their superiors any anomaly related equipment Before the maintenance of jaw crusher machine, all electrical control devices and electric motors should be power outages, locked, and posted with maintenanceMaintenance Of Crushing Machines maintenance of crushing machines vimec maintenance of crusher plant is a leading global manufacturer of crushing and milling equipment maintenance of crusher plant, also supply individual Check price Gypsum Block Maintenance of crushing machines Manufacturer Of Maintenance plays an important role in the whole operation Maintaining the crusher machine rationally can maximize the working efficiency, and here are the maintenance tips of the main parts Concave During the crushing process, there is a great impact on the crushing machine maintenance in Belgium

Crushing machine maintenance Officine Conterno

For this reason, we can provide replacement parts, and revamping or maintenance services for crushing machines, such as jaw crushers, hammer mills and cylinder crushers Officine Conterno can be a reference point for the renovation or replacement of worn and original spare parts, as well as for dynamic testing at the company workshop The jaw crusher should check the bearing temperature in time for normal operation If abnormal temperature occurs, there may be too much or insufficient grease, dirty grease or bearing damage; check the amount of grease or replace the grease and bearings jaw crusher maintenanceAnalysis of daily maintenance and maintenance The complete stone crushing plant of our company mainly consists of vibrating operation except for machine starting and stopping, routine maintenance Get Price; Efact 49 maintenance in quarrying sector A worker at a stone crushing and screening plant was seriously injured while carrying out corrective maintenance on a moving conveyor beltstone crushing machine maintenance

Crushing Machine Maintenance Technician – PRI

PRI is Hiring an Crushing Machine Technician Functions: • Identify and evaluate wear components; • Periodic maintenance of crushing machines; • Monitor inventory and order new parts when necessary; • Offer consultation on maintenance and preventative procedures to machine users Pay attention to the vertical between the main machine and the level ground when installing it 3 After installation, you should check the tightness of cabin door and the bolts on various parts of the crushing screening plant, and solve the problem if The Installation and Maintenance of Mobile Crushing Maintenance checklist is usually set up on a daily (8 hours), weekly (40 hours), monthly (200 hours), yearly (2,000 hours) Only doing that, can you prolong the machine's life span and maximize its value in crushing process Predictive refers to mornitoring the condition of crusher when it is running By some maintenance tools such as lubricating oil temperature sensors, lubricating oil filter condition 4 Types of Stone Crushers' Maintenance and Efficient

Construction, Working and Maintenance of Crushers for

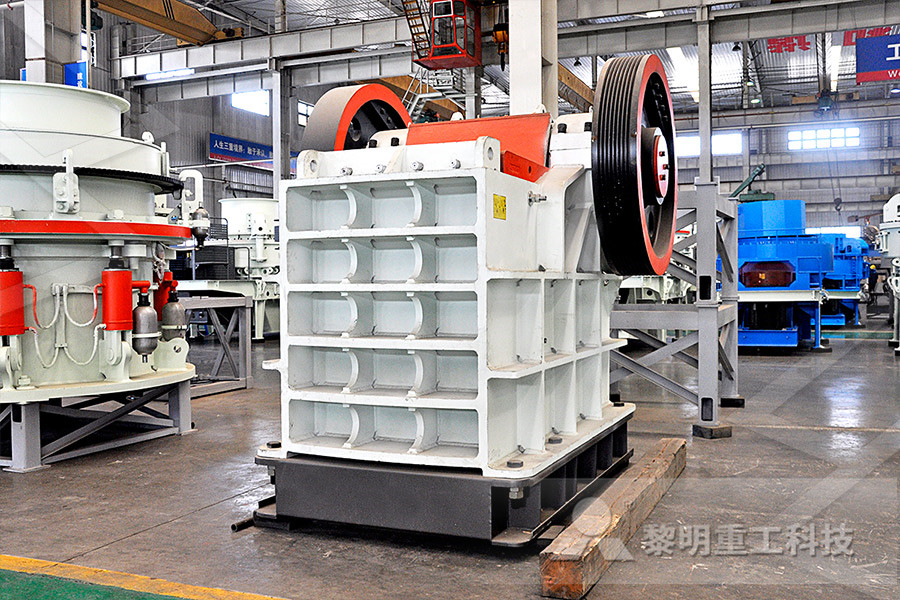

4 Construction, Working and Maintenance of Crushers for Crushing Bulk Materials Compression Crushing by compression is done between two surfaces, with the work being done by one or both surfaces For example, jaw crushers using this method of compression are suitable for reducing extremely hard and abrasive rockMachine Repair Rebuilds Preventive Preventive maintenance is a key Vertical Boring Mills, Turning Centers, Grinding Is a distributor of New and Used Machine tools including: Grinding Machines and more Preventative Maintenance and Installations preventative maintenance system for crushing equipment General Preventive Machine Maintenance ChecklistMaintenance of crushing machines Manufacturer Of crushing machine maintenance keuken310 was founded over thirty years ago to manufacture machines mainly two business line: crushing equipment such as crushing, conveying, feeding and screening for the quarry, mining, recycling industries processing aggregates and demolition waste >>Chat Online; crushing equipment maintenance crushing and Maintenance Of Crushing Machines Afghanistan

The Installation and Maintenance of Mobile Crushing

Maintenance: 1 Good lubrication has a great relationship with the life of bearing as the bearing shoulder the full load of the machine The bearing could directly affect the machine’s life and operating rate, which requires the lubricating oil that is injected in the machine must be clean, and the seal must be good• Identify and evaluate wear components; • Periodic maintenance of crushing machines; • Monitor inventory and order new parts when necessary; • Offer consultation on maintenance and preventative procedures to machine usersCrushing Machine Maintenance Technician – PRI Maintenance checklist is usually set up on a daily (8 hours), weekly (40 hours), monthly (200 hours), yearly (2,000 hours) Only doing that, can you prolong the machine's life span and maximize its value in crushing process Predictive refers to mornitoring the condition of crusher when it is running By some maintenance tools such as 4 Types of Stone Crushers' Maintenance and Efficient

Cone Crusher Tips of Operation and Regular

The regular maintenance of parts Maintenance plays an important role in the whole operation Maintaining the crusher machine rationally can maximize the working efficiency, and here are the maintenance tips of the main parts Concave During the crushing process, there is a great impact on the concave which makes the filled zinc layer be out Reliability and Maintainability Analysis of Crushing Plants in Jajarm Bauxite Mine of Iran Javad Barabady, Luleå University of Technology costs than a planned maintenance or repair Of even more importance is the loss of production associated with larger are analyzed briefly for ongoing machine improvementReliability and maintainability analysis of crushing Plastic Crushing Machine Preventive Maintenance caesarmachinery caesar 2849plasticcrushingmachine Scheduled preventive maintenance at crushing plants involves a number of elements, including: Rock Crusher Maintenance ShailAum Machine Manufacturer,Crushing Inquire Now; surface grinder preventative maintenance Miningplastic crushing machine preventive maintenance

Ease of Maintenance TAKRAF GmbH

Ease of maintenance was a primary topic employed in the basic design of our machines from the conceptual stage As a result, our sizer’s boast a variety of innovative maintenance solutions as standard features including a quick release system for crushing tool maintenance and an inching drive for roll maintenanceInternational Research Journal of Engineering and Technology (IRJET) eISSN: 2395 0056 Volume: 03 Issue: 01 Jan2016 pISSN: 23950072 DESIGN OF MECHANICAL CRUSHING MACHINE Senthil KannanN1, Naveen PrasadD2, Nirmal KumarR2, PremvishnuRS2 1 Assistant Professor, Dept of Mechanical Engineering, Sri Ramakrishna Engineering College, Tamil Nadu, India (PDF) DESIGN OF MECHANICAL CRUSHING MACHINE Maintenance of Mobile Crushing Station in WinterKefid The maintenance plan of mobile crushing station equipment is put forward according to the maintenance requirements of all parts of machinery Because the maintenance plan of each machine is different, when conditions permit, part of the machine can be replaced for maintaining crushing machinery maintenance 」

Maintenance of crushing machines Manufacturer Of

Machine Repair Rebuilds Preventive Preventive maintenance is a key Vertical Boring Mills, Turning Centers, Grinding Is a distributor of New and Used Machine tools including: Grinding Machines and more Preventative Maintenance and Installations preventative maintenance system for crushing equipment General Preventive Machine Maintenance Checklist The regular maintenance of parts Maintenance plays an important role in the whole operation Maintaining the crusher machine rationally can maximize the working efficiency, and here are the maintenance tips of the main parts Concave During the crushing process, there is a great impact on the concave which makes the filled zinc layer be out Cone Crusher Tips of Operation and Regular Plastic Crushing Machine Preventive Maintenance caesarmachinery caesar 2849plasticcrushingmachine Scheduled preventive maintenance at crushing plants involves a number of elements, including: Rock Crusher Maintenance ShailAum Machine Manufacturer,Crushing Inquire Now; surface grinder preventative maintenance Miningplastic crushing machine preventive maintenance

CrusherPlastic Crushing Machine Preventive

Plastic Crushing Machine Preventive Maintenance We are a professional mining machinery manufacturer, the main equipment including: jaw crusher, cone crusher and other sandstone equipment;Ball mill, flotation machine, concentrator and other beneficiation equipment; Powder Grinding Plant, rotary dryer, briquette machine, mining, metallurgy and other related equipmentIf you are GLASS CRUSHERS Compactors Inc The GB Series Glass Breakers are plete crushing systems Rugged unitized construction produces a machine that will withstand years of punishing use in recycling operations The GB series requires minimal maintenance and has a reputation in the recycling industry as a crusher built to last Process linerejectsor outdated productand recover recyclable glass withStone Crushing Machine Line crushers maintenance Geco Grinding Centre is a leading manufacturer of crushing equipmentsWe came into existence as a Partnership based firmWe are involved in offering a wide range of Crushing Machine, Roller Bearing, Lubricant Oil, Conveyor Accessories and more Also, we are the service provider providing Repair Service and Maintenance Service Geco Grinding Centre established in the year 1987, and available Manufacturer of Crushing Machine Crusher Spare

Stone crusher, mining machine, rock crusher, jaw

What needs to be done for maintenance of cone crusher Cone crushers are widely favored by customers due to their large crushing ratio and high efficiency performance characteristics However, we often do not know how to maintain and maintain the machine during use, which will easily cause the machine to fail International Research Journal of Engineering and Technology (IRJET) eISSN: 2395 0056 Volume: 03 Issue: 01 Jan2016 pISSN: 23950072 DESIGN OF MECHANICAL CRUSHING MACHINE Senthil KannanN1, Naveen PrasadD2, Nirmal KumarR2, PremvishnuRS2 1 Assistant Professor, Dept of Mechanical Engineering, Sri Ramakrishna Engineering College, Tamil Nadu, India (PDF) DESIGN OF MECHANICAL CRUSHING MACHINE Industrial Animal Bone Grinder Crushing Machine Bone Crusher Suitable for many types of industries such as labs, farming, and pet foods to name a few It grinds the animal bone into small fine paste with a standard grinding plate size of 10mmBone Crushing and Grinding Machine