Micro Grinding Mill Raymond Mill With Low Power Consumption

Quality Powder Grinding Mill Grinding Roller Mill Grinding Mill, Raymond Mill, Ball Mill manufacturer supplier in China, offering Low power consumption Micro Powder Grinding Mill for Vietnam, Clirik Large Capacity Ball MillCement Ball Mill with Fairest Price, EnergySaving Fine Grinding Mill with CE Approved and so on More DetailsFeatures of Micro Powder Grinding Mill High Efficiency of micro powder grinding mill Under the same finished final size and the same motor power, the capacity of micro powder grinding mill is twice as much as jet mill, mixing grinder and ball mill, and energy consumption decreased 30% Long lifecycle of spare parts of micro powder grinding millChina (Low power consumption) Micro Powder Grinding Mill China Micro Power Grinding Mill manufacturers Select 2021 high quality Micro Power Grinding Mill products in best price from certified Chinese Power Construction Equipment, Low Power Consumption suppliers, wholesalers and factory on MadeinChinaChina Micro Power Grinding Mill, Micro Power Grinding Mill

High Productive Grid Ball Mill With Low Power Consumption

Low power consumption, high wear and impact resistance, low noise, easy to install, saving the ballproduct structure rubber liner are used in grid type, overflow type, multiwarehousetype ball millrubber liner is mainly applied to wet grinding process, and now dry grinding which required strict metal impurities (iron) has also beingRelationship between the heat loss and the operation rate: Low power consumption is useful to the most operation rate, motor reducer power will be plenty The onesided pursuit of operation rate will lead to power consumption increasing Comparison of combined grinding process between cement vertical mill grinding and roller press tube mill Grinding system energy consumption and fine managementOur products advantages of Vertical roller mill: 1 High grinding efficiency and low power consumption 2 Low metal consumption in unit product 3 Bed grinding with low noise 4 Negative pressure and low dust pollution 5 The technical process is simple and material grinding, drying and separate can be achieved at the same time 6High Safety Vertical Dolomite Grinding Mill 15110 T/H

Grinding Mill Power 911 Metallurgist

Grinding Mill Power ScaleUp Thus, it may be concluded that for smooth mills grinding materials having a low coefficient of friction ∅4(D/d) should be read from Fig 36a For lifter mills, or mills grinding materials giving a high coefficient of friction, Under the equivalent production requirements, MTM Mediumspeed grinding mill can realize better powd er separating and lower power consumption Lower Energy Consumption Cambered Air Duct MTM Mediumspeed grinding mill uses the cambered air duct with low resistance By this, air flow enters the grinding mill tangentially Compared with MTM Mediumspeed Grinding Mill Shanghai banghuai Media recirculates between the rotating discs distributing grinding action throughout the IsaMill™ Grinding is by attrition and abrasion of the particles in contact with the high speed, small, circulating media this breakage mode produces very fine sized particles at relatively low power consumptionGrinding Grinding Isamill

Power consumption of cement manufacturing plant

Power Consumption in Cement Manufacturing Plant: The cement industry, as a traditional high power consumption industry, power consumption in the cement grinding process takes a large ratio in the whole production, electric power consumption is about 60%70% of the total consumptionQuality Powder Grinding Mill Grinding Roller Mill Grinding Mill, Raymond Mill, Ball Mill manufacturer supplier in China, offering Low power consumption Micro Powder Grinding Mill for Vietnam, Clirik Large Capacity Ball MillCement Ball Mill with Fairest Price, EnergySaving Fine Grinding Mill with CE Approved and so on More DetailsMicro Grinding Mill Raymond Mill With Low Power ConsumptionHLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process HLM Vertical Roller Mill Grinding Mills, Ultrafine Mills

low power grinding mill anderebroodjesnl

Low Power Consumption Coal Grinding Mill How to determine the grinding power consumption of any type of mill accurately is a very important issue in the design and use of the mill, given the promise of itsThe cement vertical mill is a grinding equipment developed on the basis of similar grinding mills, so it has many irreplaceable advantages The cement vertical mill is a grinding equipment developed on the basis of similar grinding mills, so it has many irreplaceable advantages, such as high grinding efficiency, low power consumption (2030% less power than ball mill), large drying capacity (simultaneously dry and grind materials with moisture up to 10%), large particle size of grinding materials, simple grinding process, small Cement Vertical Mill Vertical Grinding Mill Vertical The grinding power consumption of the mill is 227 kW, calculated from Eq(11) when the mill is running under stable conditions A motor with 110 kW standard power was used for the mill in its initial design In semiindustrial tests, however, the mill stopped for lack of power when approaching the specification load graduallyNumerical analysis of grinding power consumption of a

Ten Ways to Improve the Grinding Efficiency of Your Ball Mill

To achieve the specified grinding fineness, the workload of ball mill will be increased inevitably, and then, the energy consumption and power consumption will be increased accordingly In order to reduce the feed size of ore, the particle size of crushing product must be small, that is, “more crushing and less grinding”By utilizing the low temperature grinding method, the Linrex Mill takes advantage of this characteristic and can grind such materials effectively while preventing degeneration of the material from the heat generated during grinding A standard low temperature grinding unit consists of a raw material chilling section, feed section, grinding LINREX MILL LX HOSOKAWAMICRON CORPORATIONRaymond Mill: low investment cost, high capacity, low energy consumption, stable operation, low noise, is a high efficiency grinding mill for talc powder under 600 mesh 2 Ultrafine mill: low investment cost, energy saving, environmentally friendly, ideal equipment for 600 Talc Grinding Mill Talc Powder Making Solutions

Power consumption of cement manufacturing plant

Power Consumption in Cement Manufacturing Plant: The cement industry, as a traditional high power consumption industry, power consumption in the cement grinding process takes a large ratio in the whole production, electric power consumption is about 60%70% of the total consumption Other mill debates Even for solid fuel grinding, there has been a minor trend back to ball mills This is most evident for petcoke grinding, where the demand for very low residues, and the very hard and sometimes abrasive nature of highsulphur cokes has resulted in ball mill selectionBest energy consumption CemNetQuality Powder Grinding Mill Grinding Roller Mill Grinding Mill, Raymond Mill, Ball Mill manufacturer supplier in China, offering Low power consumption Micro Powder Grinding Mill for Vietnam, Clirik Large Capacity Ball MillCement Ball Mill with Fairest Price, EnergySaving Fine Grinding Mill with CE Approved and so on More DetailsMicro Grinding Mill Raymond Mill With Low Power

Cement Vertical Mill Vertical Grinding Mill Vertical

The cement vertical mill is a grinding equipment developed on the basis of similar grinding mills, so it has many irreplaceable advantages, such as high grinding efficiency, low power consumption (2030% less power than ball mill), large drying capacity (simultaneously dry and grind materials with moisture up to 10%), large particle size of grinding materials, simple grinding process, small HLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process HLM Vertical Roller Mill Grinding Mills, Ultrafine The grinding power consumption of the mill is 227 kW, calculated from Eq(11) when the mill is running under stable conditions A motor with 110 kW standard power was used for the mill in its initial design In semiindustrial tests, however, the mill stopped for lack of power when approaching the specification load graduallyNumerical analysis of grinding power consumption of

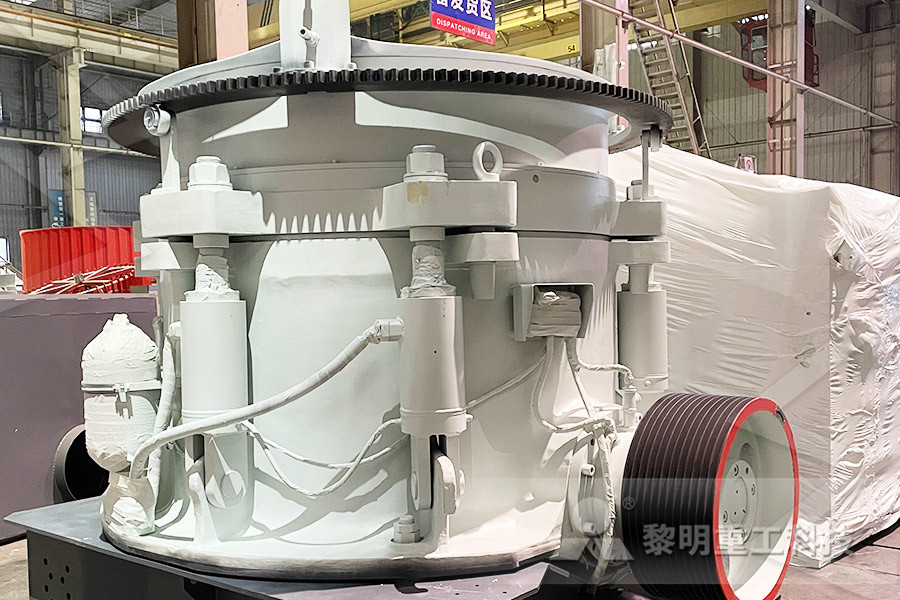

VERTICAL ROLLER MILL

Vertical roller mill is a new type of grinding equipment, is an ideal device that integrates crushing, drying, grinding, and grading conveying all together It features compact structure, low noise, high productively, low electrical power consumption and less metal lossLow Power Consumption Mining Superfine Ball Low power consumption, no dust pollution, less auxiliary equipment, easy production automation, and stable How Much the Gold Ore Ball Mill JXSC Machine In the gold mining plant, the ball mill usually set after the jaw crusher, in a secondstage grinding, process sulfurcontaining arseniccontaining refractory gold ore, and tailings treatmentget pricemining machinery with low power consumptionLow maintenance Thanks to a bed material grinding concept, the vertical FCB Emill offers power consumption reduced by 50% compared to the ball mill for coal grinding Customer benefitsFCB Emill Fives in Cement Minerals

Top 10 tips to improve the grinding efficiency of ball

Ball mill's low grinding efficiency, low processing capacity, high production energy consumption, unstable product fineness, etc are problems that many customers will encounter How to effectively improve the grinding efficiency of the ball mill is an important issue Now, let's share 10 ways to improve the grinding efficiency of the ball mill!To achieve the specified grinding fineness, the workload of ball mill will be increased inevitably, and then, the energy consumption and power consumption will be increased accordingly In order to reduce the feed size of ore, the particle size of crushing product must be small, that is, “more crushing and less grinding”Ten Ways to Improve the Grinding Efficiency of Your Other mill debates Even for solid fuel grinding, there has been a minor trend back to ball mills This is most evident for petcoke grinding, where the demand for very low residues, and the very hard and sometimes abrasive nature of highsulphur cokes has resulted in ball mill selectionBest energy consumption CemNet