of crushing of raw materials for cement

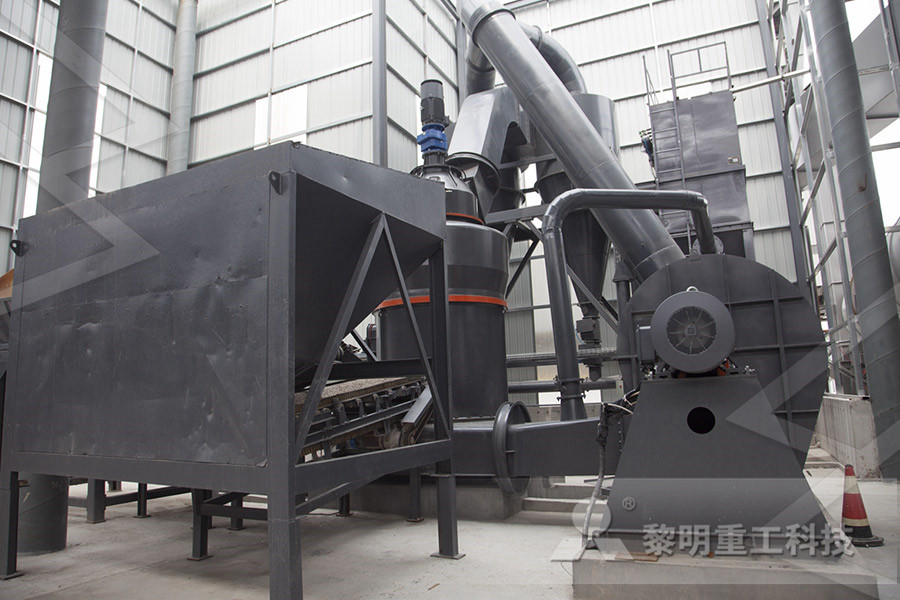

Cement Crushing Grinding Plant In cement production process cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement such as limestone clay iron ore and coal etc Limestone is the largest amount of raw material during cement production Get Price; crushing of raw material for Production Grinding Crushing Storage Cement Industry Education Hanson HeidelbergCement in the United Kingdom Please come and learn how we make our cement Getting the raw materials and crushing them 2 Cement grindingThe whole production process is monitored and controlled from a central control The crushed material is transported into the How Is Crushing In Cement Industry Done Cement Crushing Grinding Plant, So cement is kind of cementitious material which will be of stronger hardness in water Cement mil is used for cement grinding Cement crusher is applied for cement crushing In cement mining, you need to choose suitable cement grinding mill and cement crusher Production process Three stages: 1Crushing In Cement Plant virtualprohlidkycz

crusher details in cement production

Cement production line is sample: the big stones in the stone production line are coarsely crushed in the jaw crusher, then be sent by the vibrating feeders through the bunker evenly After tertiary crushing, the materials are screened in the vibrating screen through the belt conveyor to As a cement plant manufacturer, AGICO not only produces cement production lines, stone crushing plant, but also manufactures many cement equipment, such as a series of cement crushers required for cement raw material crushingCement Crusher – Crusher In Cement Plant AGICO Cement Crushing Processing Plant Portable cement crusher in cement is an new cement crusher in cement processing plant posted in cement crusher crushing plant 247 online crushing plant for concrete processing gulin machine in iron ore processing plant mobile concrete crushing compani get prices stone crushing screening plant for concrete aggregateCrusher In Cement Plant Processing Plant

Cement Manufacturing Plant Cement Plant AGICO

For different stages in the cement manufacturing process, AGICO offers various EPC projects of cement manufacturing plants: cement production lines, stone crushing plants, cement grinding units, fly ash processing plants, and VSK cement plant All of these EPC projects can highly meet your needs for cement production two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow diagram below; 1 Quarrying and Crushing 2 Raw material Storage and Transportation 3 Proportioning 4 Raw material Grinding and Transportation 5 CEMENT PRODUCTION AND QUALITY CONTROL A cement production are as follows: • Improving capacity utilisation • Energy savings • Improved environment • Use of waste heat • Use of byproducts, wastes, alternative raw materials and fuels • Meeting market requirements in terms of quality and types of cement ie Quality assuranceModern Processing Techniques to minimize cost in

Daswell Cement Crushing Plant Operationcnm2386的博客

In some production sites, we use a whole mobile crusher to complete the whole cement crushing and screening production since the mobile crusher is equipped with jaw crusher, impact crusher or cone crusher, vibrating feeder,vibrating screen,etccrushing in cement production The first procedure for producing cement is to break up raw materials and limestone is the main raw material for cement production Since the limestone is mined and the hardness is high the jaw crusher that specializes in crushing limestone becomes a better raw material crushing equipment on the cement production line The jaw crusher has many advantages to prove crushing in cement production VETURA Heavy Cement Crushing Grinding Plant In cement production process cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement such as limestone clay iron ore and coal etc Limestone is the largest amount of raw material during cement production Get Price; crushing of raw material for of crushing of raw materials for cement

crushing raw materials for cement production in

Crushing plant for raw materials: jaw crusher, gyratory crusher, impact crusher, cone crusher etc Cement grinding mill: grinding occurs at the beginning and the end of the cement making process Grinding mill is the important machinery in cement productionCement Production an overview ScienceDirect Topics Cement production is a thermal energy intensive process, This stage includes the process of siege, crushing, and prehomogenization Typical raw materials used for cement production have 85% cayenne, 13% clay or blackboard, and under 1% each of materials such as silica, alumina, and iron orecement production and crushing schroniskogoldappl The cement production line is a complex production line specializing in the production of cement The production line is mainly composed of crushing and prehomogenization, raw material preparation homogenization, preheating decomposition, cement clinker burning, cement grinding and packaging, and each process is independent and interconnectedSolutionsCement Production LineTianli Energy

Stone Crushing Plant Automatic Stone Crusher Plant

AGICO provides the impact crusher, jaw crusher, cone crusher, vibrating feeder, belt conveyor, vibrating screen and other cement equipment used in stone crushing plant We offer different crushing mills and design plans according to the customer's specific production needsCement production equipment and technology is the advantage of my plants ,my plant the production of cement rotary kiln, cement mill can be used in 50 tons to 1500 tons/day of cement plant Feature: high production capability environmental friendly advanced technology Lower investment Easy maintenanceCement Production PlantCemet Production Solutions Cement Production Line Cement production line is also known as the dry type cement production line, with high productivity and high degree of automation; Stone Production Line Stone production line is the sand production line, special for crushing gravel and stoneJaw Crusher/Impact Crusher/Crusher/Hammer

Daswell Cement Crushing Plant Operationcnm2386的博客

Also cement conveyor is used to transport these materials to next procedure, such as vibrating cement screen to screen out required fineness In some production sites, we use a whole mobile crusher to complete the whole cement crushing and screening,1500t / d cement production line Pengfei EPC cement production line project includes process design, equipment supply (including mechanical and electrical parts), civil engineering, installation and commissioning, trial operation, reaching the production standard and final delivery and other services1500t / d cement production line 3 Cement production 31 Introduction 32 Cement production process 321 Crushing of limestone, alumina etc 322 Drying/mixing 323 Coarse grinding 324 Dosage/mixing 325 Burning the raw meal/cooling the clinkers 326 Cement clinker storage 327 Fine grinding of clinker 328 Cement storage/transport 4 SummaryCrushing of hard materials / Grading (screening) Cement

of crushing of raw materials for cement

Cement Crushing Grinding Plant In cement production process cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement such as limestone clay iron ore and coal etc Limestone is the largest amount of raw material during cement production Get Price; crushing of raw material for process of manufacturing of aggregates part a crushing Cement Crushing Grinding Plant, In cement production process, cement crusher is very important since most of the raw materials will have to be crushed before being used to process cement, such as limestone, clay, iron ore Get Pricecement aggregates washing and crushing process In the cement production process, most of the raw materials are broken, such as limestone, clay, iron ore and coal Limestone is the raw material for producing the largest amount of cement After mining, the particle size is larger and the hardness is higherCement production line crushing system position

Crushing plant Fives in Cement Minerals

FCB Rhodax® 4D The FCB Rhodax ® 4D, by replacing 2 to 3 stages of crushing and grinding, enables a 10 to 25% energy savings compared to traditional crushing technologies The interparticle crushing ensures a constant product quality, with constant particle size distribution and capacity, since these parameters are not linked with the worn shape of linersThe high flexibility of this inertial As a cement plant manufacturer, AGICO not only produces cement production lines, stone crushing plant, but also manufactures many cement equipment, such as a series of cement crushers required for cement raw material crushing: cone crusher, impact crusher, hammer crusher, jaw crusher, and fourroll crusherCement Crusher – Crusher In Cement Plant AGICO Cement Process Flow of Cement Making Plant 1 Crushing and Prehomogenization (1) Crushing In the cement production, most of the raw materials need crushing, such as limestone, clay, iron ore, coal, etc The limestone is of large particle sizes and high hardness after being mined Therefore, the limestone crushing is the most essential part in cement : Cement Production Line,Cement Plant,Cement

CEMENT PRODUCTION AND QUALITY CONTROL A

two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow diagram below; 1 Quarrying and Crushing 2 Raw material Storage and Transportation 3 Proportioning 4 Raw material Grinding and Transportation 5 AGICO dry process cement production line comprehensively adopts the IT technology, multifunction grinding system, newtype wearresisting and heatresisting materials, mechanical powder conveying device, and some other modern technologies to realize quality cement production It has the characteristic of energy saving, high efficiency, environmental protection, and low emissionCement Production Line Cement Manufacturing Plant Cement can also be packaged with or with no color addition and distributed by truck or rail stone processing plant Singlestage hammer crusher This kind of crusher is appropriate in crushing medium strength ore for instance limestone, marlite, slag, gypsum and coalSinglestage Hammer Crusher Used in Cement Crushing