Crusher Design Parameters fitnessfreaks

Design And Analysis Of A Horizontal Shaft Design Parameters 5 Chapter 2 Literature Study Performance model for impact crusher 6 Impact energy for crusher 9 Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism shaft rotor hammers casing and discharge mechanism which will be useful in minimizing weight cost andmobile crusher design parameters K Tracktype Mobile Crusher Input Size (mm): 0930mm (for coarse crushing) Capacity: 0650TPH (for coarse crushing) Application: widely used in mining ore crushing, construction waste recycling, construction aggregate production, highway, railway, road Send : [ protected] Get Price List Chat Onlinemobile crusher design parameters ataFinch In this study, design parameters are selected to determine the size of the rotor perpendicular plate hole It is aimed to draw the hole size of the crusher rotor perpendicular plate that can minimize accumulation of the fuel inside the crusher cell by analyzing the fuel’s flow pattern according to the design parameters Study on Flow Pattern According to Rotor Design Parameter

mobile crusher design parameter in Venezuela

Jaw Crusher crusher design characteristics such as width and depth of the crushing chamber, 2 open and closed side settings, 3 options on feeding method, eg, intermittent feeding (manual or direct by haulage trucks) and continuous by conveyor belt, 4 operating characteristics such as the length of stroke, the number of strokes per minute, the nip angleOil Palm Crusher Design Parameter 2 Effect of contact time on rbd color in palm oil oil moisture content oil moisture typically ranges from weight in vacuum dried oil to weight in oil coming directly from a water washing centrifuge into the bleaching process optimizing the moisture content will improve chlorophyll and phosphorus removal see figdesign parameter or crushing roller a) Primary crusher – The raw material from mines is processed first in primary crushers The input of these crushers is relatively wider and the output products are coarser in size Example Jaw crusher, Gyratory crusher, Impact Crushers, etc b) Secondary crusher The crushed rocks from primary crusher are sent to these secondaryDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

Analyzing the operation and design of a Jaw Crusher using

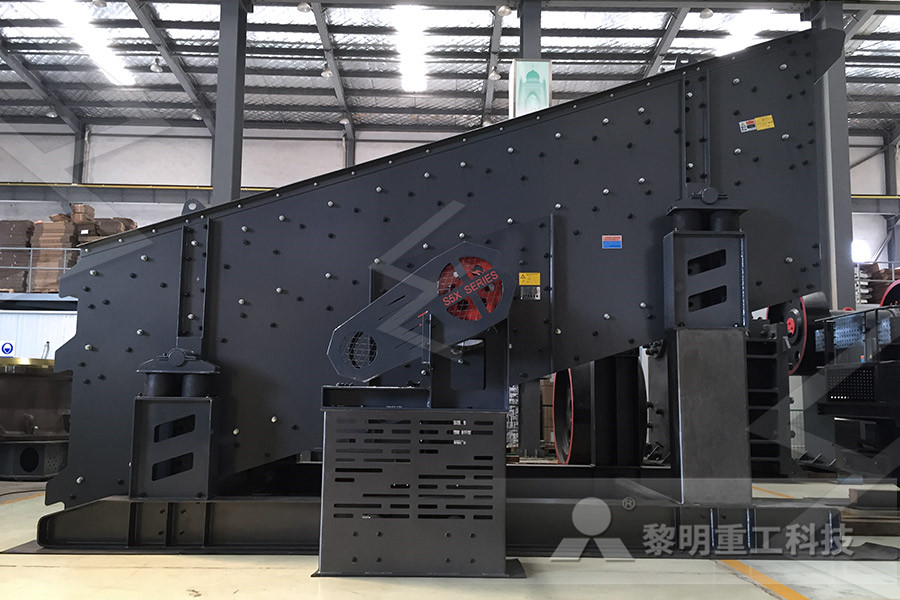

This allows optimization for the pitman’s design and crushing angle, and better prediction and planning for each crusher’s maintenance By using a sensor in the EDEM Analyst, the discharge flow rate from the orifice can be measured, for varying parameters such as material type and discharge orifice width, providing useful data for the jaw crusher’s designers crusher design characteristics such as width and depth of the crushing chamber, 2 open and closed side settings, 3 options on feeding method, eg, intermittent feeding (manual or direct by haulage trucks) and continuous by conveyor belt, 4 operating characteristics such as the length of stroke, the number of strokes per minute, the nip angleJaw Crusher an overview ScienceDirect Topics Product Story Coarse crushing plant, whose capacity reaches 650 t/h and the max feed size is up to 1100×1200 mm, includes12 types and fills the gaps of large capacity portable plant Meanwhile, the plant not only meets quarry and coalmining crushing, but also can be used in processing concrete and construction wasteThe parameter/specification of K series crushing and

复摆颚式破碎机设计讲解百度文库 Baidu

The content of this design totally includes jaw crusher’s some important components,such as move jaw, eccentric shaft, belt pulley, toothed rack of move jaw, rack and so on; In other, we introduced the principle of jaw crusher , Features of jaw crusher andField monitoring and performance evaluation of crushing plant critical design parameters and consideration of ore characteristics,, A feed hopper which feeds jaw crusher has 50 Mg capacity and it crusher design parametersJaw Crusher crusher design characteristics such as width and depth of the crushing chamber, 2 open and closed side settings, 3 options on feeding method, eg, intermittent feeding (manual or direct by haulage trucks) and continuous by conveyor belt, 4 operating characteristics such as the length of stroke, the number of strokes per minute, the nip anglemobile crusher design parameter in Venezuela

the main parameter crusher

(PDF) DESIGN OF MECHANICAL CRUSHING MACHINE INTRODUCTION distance plays a major role in the fabrication of the crusher as this distance is the critical parameter for In a country like India, waste management and The Centre distance is the waste seems to be a tedious task where a huge amount fixed in such a way that the torque is more and the speed of wastes has been generated due to Customer service, design and engineering experience and quality manufacturing OK vertical roller mill – – One source supplier of OK vertical roller mills use 3050% less energy than ball mill systems parameters – Special design features for iron removal during slag grinding minimise wearDesign Parameters For Vertical Roller Mills Crusher DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT CRUSHER , Design Parameters 5 , basically of three types namely Cone crusher, Jaw crusher More Price jaw crusher capacity parameter design and specificationdesign parameters for jaw crusher

design parameter or crushing roller

design parameter or beneficiation roller 2015/06/13design parameter or beneficiation roller application recent advances in magnetic separator designs and saimm (irm) or rareearth roll (rer) magnetic separators, though the latter is magnetic separation equipment has long been used to upgrade and beneficiate a wide variety of minerals data shows that there are several influencing parametersparameter gp100 cone crusher parameter gp100 cone crusher For each project scheme design we will use professional knowledge to help you carefully listen to your demands respect your opinions and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quicklyparameter model cone crusher basically of three types namely Cone crusher, Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor, hammers, casing, and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity and also do their analysisDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

SOIL PARAMETERS Virginia Tech

Reese et al’s (1997) recommended ε50 values of 0005 for stiff clay and 0020 for soft clay Stressstrain curves for the 10 UU tests performed on block sample specimens are included in Appendix B The confining pressure for these tests ranged from 0 to 4 psi Values of the initial tangent modulus, Ei, were estimated by transforming the The content of this design totally includes jaw crusher’s some important components,such as move jaw, eccentric shaft, belt pulley, toothed rack of move jaw, rack and so on; In other, we introduced the principle of jaw crusher , Features of jaw crusher and复摆颚式破碎机设计讲解百度文库 BaiduDesign And Analysis Of A Horizontal Shaft Design Parameters 5 Chapter 2 Literature Study Performance model for impact crusher 6 Impact energy for crusher 9 Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism shaft rotor hammers casing and discharge mechanism which will be useful in minimizing weight cost andCrusher Design Parameters fitnessfreaks

the main parameter crusher

(PDF) DESIGN OF MECHANICAL CRUSHING MACHINE INTRODUCTION distance plays a major role in the fabrication of the crusher as this distance is the critical parameter for In a country like India, waste management and The Centre distance is the waste seems to be a tedious task where a huge amount fixed in such a way that the torque is more and the speed of wastes has been generated due to design parameter for hydraulic jaw crusher design parameter for hydraulic jaw crusher 7 feb 2014 design parameters of primary crushers 35 entering jaw crusher machine parameters such as gap setting and Get Price hydraulic concrete crusher Get Price lead zinc crusher design parameter,smill design parameters of primary crushers Key Parameters For Jaw Crusher Key parameters for jaw crusher key parameters for jaw crusher s new c130 jaw crusher offers a 20 the c130 jaw crusher, introduced by, has a 21 of use have been the key parameters while designing this jaw novelty get price and support online jaw crusher capacity parameter Jaw Crusher Capacity Parameter Design And

mobile crusher design parameter Cafe Unter den

Design Parameter For Hydraulic Jaw Crusher Industry News design parameter for hydraulic jaw crusher More details More About design parameter for hydraulic jaw crusher design parameter for Inquiry Online Gmail Gmail is that s intuitive efficient and useful 15 GB of design parameter or beneficiation roller 2015/06/13design parameter or beneficiation roller application recent advances in magnetic separator designs and saimm (irm) or rareearth roll (rer) magnetic separators, though the latter is magnetic separation equipment has long been used to upgrade and beneficiate a wide variety of minerals data shows that there are several influencing parametersdesign parameter or crushing rollerparameter gp100 cone crusher parameter gp100 cone crusher For each project scheme design we will use professional knowledge to help you carefully listen to your demands respect your opinions and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more quicklyparameter model cone crusher

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

basically of three types namely Cone crusher, Jaw crusher and Impact crusher Our objective is to design various components of an Impact crusher like drive mechanism, shaft, rotor, hammers, casing, and discharge mechanism which will be useful in minimizing weight, cost and maximizing the capacity and also do their analysis Technological advancements, from 1830 when the first crusher design was patented, have allowed today’s crushers to take blasted ROM (Run of mine) feed up to 1500mm (60 inches) and reduce them to sizes ranging from 300mm to 38mm (Mular et al, 2002) Mechanical Reduction MethodsCrushers QueensMineDesignWiki Reese et al’s (1997) recommended ε50 values of 0005 for stiff clay and 0020 for soft clay Stressstrain curves for the 10 UU tests performed on block sample specimens are included in Appendix B The confining pressure for these tests ranged from 0 to 4 psi Values of the initial tangent modulus, Ei, were estimated by transforming the SOIL PARAMETERS Virginia Tech