High Clay OresA Mineral Processing Nightmare Part 2

processing high clay ores These clay minerals typically form in near surface geological environments due to weathering, particularly above the natural water table, sedimentation and diagenesis and are common in hydrothermally altered rocks Clay minerals associated with alteration is referred to as Argillic alterationwaste dilution from country rock containing clay can adversely affect the process There are some solutions which assist in processing high clay ores but do not negate all of the difficulties The presence of clays has a major influence on the process selection and equipment used in the final flowsheetThe Difficult Mineral Processing Issues with Processing impacts The mineral industry’s understanding of the issues and solutions of clayrelated processing issues remains poor and in many cases the processing problems associated with clays are simply avoided by not processing the ores As operators we approach the problem of processing high clay ores by finding chemical andThe Difficult Mineral Processing Issues with Clay Ores

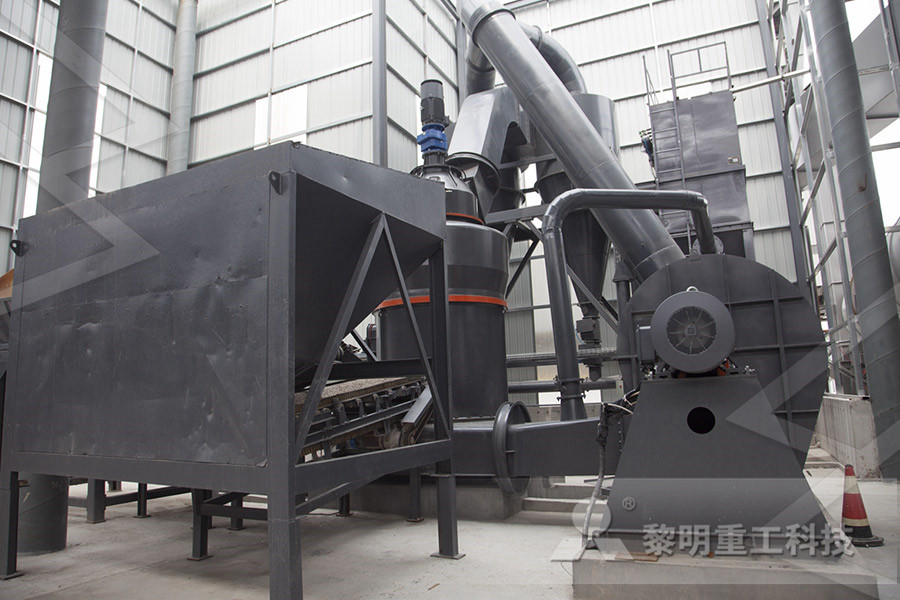

Processing clay gold oreHenan Mining Machinery

Mining of ore for heap leaching employs the same techniques and equipment as mining of ore to feed any other process method Where uncrushed ore (runofmine (ROM) ore) is placed on the leach pad, ore may be blasted very heavily in order to reduce rock size and improve gold recovery In highrainfall environments when processing clayrich > Mineral Processing > RESOURCE PROJECTS > TECHNOLOGY > INTEGR > Engineering Design > Training > Specialist ServicesATED SERVICES Heap Leaching > High clay ores require agglomeration with cement in an agglomeration drum and time to cure before stackingThe Difficult Mineral Processing Issues with Processing Processing of high clay ores is usually related to negative effects in particular in the flotation stages A good description was made recently in the work by Chen and Peng (2018), who developed a general review about the mechanisms and behaviour of clays in mineral flotation The background they presented is general and useful for any situation in which clays appear since most of the challenges The effect of clay minerals on the process of flotation

processing high clay material for gold

processing high clay material for gold For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more That is commonly done for highgrade ores simply by rejection in the beneficiation processes into lessmagnetic or nonmagnetic tailings or lower density tailings and in some cases by reverse flotation of silicates or apatite Selective flocculation, such as used at Processing HighGrade Concentrates from The most convenient processing alternative for highsilver gold ores and concentrates is largely dependent on the quantity and mineralogy of the silver phases present As far as leaching is concerned, pretreatment of the ore or modification of the leaching chemistry may be necessary to remove or diminish the negative effects of stable precipitating anionsProcessing of HighSilver Gold Ores ScienceDirect

Aluminum processing Ores Britannica

The Bayer process involves four steps: digestion, clarification, precipitation, and calcination In the first step, bauxite is ground, slurried with a solution of caustic soda ( sodium hydroxide ), and pumped into large pressure tanks called digesters, where the processing high clay material for gold For each project scheme design, we will use professional knowledge to help you, carefully listen to your demands, respect your opinions, and use our professional teams and exert our greatest efforts to create a more suitable project scheme for you and realize the project investment value and profit more processing high clay material for goldExperimental Study on the Mineral Processing of a HighClay and Lean Hematite Article Preview Abstract: ”,a final iron concentrate with TFe grade of 6589% ,yield of 1935% and iron recovery of 5232% from the raw ores with TFe grade of 2407% was obtained, with the first stage grinding size being 50% 200 mesh and the second stage,95 Experimental Study on the Mineral Processing of a

1125 Clay Processing US EPA

1125 Clay Processing 11251 Process Description14 Clay is defined as a natural, earthy, finegrained material, largely of a group of crystalline and in pelletizing taconite iron ores Fuller’s earth is defined as a nonplastic clay or claylike material that typically is high in magnesia and has specialized decolorizing and purifying Processing High Clay Material For Gold Gold Processing Equipment like the IGR500 Alluvial gold processing plant high clay ores This video is unavailable Watch Queue Queue Watch Queue Queue Auteur Melody Wong » Drywashing for Gold Sometimes it is necessary to dig clay a couple of days ahead of the processing moregold processing high clay in sudan priceScrubber liners from Multotec are ideal for hard minerals such as diamonds, and for treatment of laterite and other high clay ores Multotec uses computer simulations to determine an optimal height to angle (H2A) to ensure cascading of the material, while keeping breakage in mind Countersunk bolts from the outside of the shell are used for tyre and roller driven scrubbersScrubber Liners Multotec Mineral Processing

Establishing thE ProcEss MinEralogy of gold orEs

Silverrich ores and copper sulfide ores: Silverrich ores and copper sulfide ores are often freemilling, but when the silver grade is high (>10 g/t) and/or the gold is present as electrum, the processing may need to be modified The greater reactivity of silver SGS MINERALS TECHNICAL BULLETIN 2004930 nature, ease of mining and processing, these clays warrant a detailed study as important sources of rare earths II Formation of Weathered Crust Elution‐deposited Rare Earth Ores (Ion‐adsorption Clays) The ion adsorption clay deposits of REE were first discovered in 1969 in the Jinangxi provinceRecovery Of Rare Earth Elements From Clay MineralsTraditionally, nickel has been processed from sulfide ores in an approach similar to copper processing, in which the ore is upgraded to concentrates and then smelted As sulfide ore resources dwindle, however, processing of lateritic nickel ores is becoming of greater necessity, with many recognizing nickel laterite ores as the future of the Processing of Nickel Laterite Ores on the Rise

Uranium processing Britannica

2 天前 The hydrometallurgical processing of uranium ores is frequently preceded by a hightemperature calcination step Roasting dehydrates the clay content of many ores, removes carbonaceous materials, oxidizes sulfur compounds to innocuous sulfates, and oxidizes any other reductants that may interfere in subsequent leaching operationsExperimental Study on the Mineral Processing of a HighClay and Lean Hematite Article Preview Abstract: ”,a final iron concentrate with TFe grade of 6589% ,yield of 1935% and iron recovery of 5232% from the raw ores with TFe grade of 2407% was obtained, with the first stage grinding size being 50% 200 mesh and the second stage,95 Experimental Study on the Mineral Processing of a 1125 Clay Processing 11251 Process Description14 Clay is defined as a natural, earthy, finegrained material, largely of a group of crystalline and in pelletizing taconite iron ores Fuller’s earth is defined as a nonplastic clay or claylike material that typically is high in magnesia and has specialized decolorizing and purifying 1125 Clay Processing US EPA

An Innovative Process for Comprehensive Utilisation

An Innovative Process for Comprehensive Utilisation of ClayVanadium Ores By adopting conventional processing technologies such as flotation, gravity concentration, and magnetic separation, it is difficult to enrich vanadium mineral effectively At present, vanadium extraction processThe quality of clay raw material is always checked before further processing Liberation of impurities allows better blending, mixing and forming to produce a more constant and reactive material when firing Our Xray fluorescence (XRF) spectrometers improve yield and margin of ceramic production by checking the quality of incoming raw materialsAnalytical Clay, Refractory Ceramic Processing Scrubber liners from Multotec are ideal for hard minerals such as diamonds, and for treatment of laterite and other high clay ores Multotec uses computer simulations to determine an optimal height to angle (H2A) to ensure cascading of the material, while keeping breakage in mind Countersunk bolts from the outside of the shell are used for tyre and roller driven scrubbersScrubber Liners Multotec Mineral Processing

Recovery Of Rare Earth Elements From Clay Minerals

nature, ease of mining and processing, these clays warrant a detailed study as important sources of rare earths II Formation of Weathered Crust Elution‐deposited Rare Earth Ores (Ion‐adsorption Clays) The ion adsorption clay deposits of REE were first discovered in 1969 in the Jinangxi provinceTraditionally, nickel has been processed from sulfide ores in an approach similar to copper processing, in which the ore is upgraded to concentrates and then smelted As sulfide ore resources dwindle, however, processing of lateritic nickel ores is becoming of greater necessity, with many recognizing nickel laterite ores as the future of the Processing of Nickel Laterite Ores on the RiseHigh carbon ferromanganese Refined Silicomanganese Chemical formula HCFeMn/FeMn MCFeMn/LC FeMn SiMn % Mn 65% 79% 80% 81% 60% 77% C 80% max 01% 35% min 01% 20% max Si 20% max 10% 35% min 20% max Other materials P 05% max 005% 035% max 015% 035% max S 003% 003% max 003% max Produced in BF Yes Produced form HCFeMn (PDF) Hydrometallurgical Processing of Manganese

Uranium processing Britannica

2 天前 The hydrometallurgical processing of uranium ores is frequently preceded by a hightemperature calcination step Roasting dehydrates the clay content of many ores, removes carbonaceous materials, oxidizes sulfur compounds to innocuous sulfates, and oxidizes any other reductants that may interfere in subsequent leaching operations Depletion of highgrade resources has necessitated the use of lowgrade fines, which contain good amount of mineral values and also liberate in finer sizes Froth flotation, a physicochemical surfacebased process, is the most established solution, both technologically and economically, compared to other alternatives for fines beneficiation For a successful and effective flotation Role of Surfactants in Mineral Processing: An