Sugar Mill Settings

Trash Plate Settings There are a number of methods of setting out a trashplate for a mill, these are discussed by Hugot, Handbook of Cane Sugar Engineering, Jenkins, Introduction to Cane Sugar Technology, 1966 and Maxwell, Modern Milling of Sugar Cane, 1932In addition a number of papers discussing this topic have been published among them Ashe, GG, SASTA, 1963 and Van Hengel, A SUGGESTIONS FOR THE: SETTING OF VERTICAL FEED CHUTES by A van Hengel 33 A FOUR ROLLER MILL by R Renton 37 MUTUAL MILLING CONTROL PROJECT (PROGRESS REPORT NO 3) by E J Buchanan, K Douwes Dekker and A van Hengel 43 PRACTICAL AUTOMATION by D L Hughes 57 SOME ASPECTS OF THE DESIGN OF MODERN INDUSTRIAL PROCEEDINGS OF THE THIRTYEIGHTH ANNUAL Cane preparation Heavy Duty inline Shredder Heavy duty vertical shredder Cane Juice Extraction FCB Inclined Head stock Mill FCB Self Setting Mill Fletcher Vertical Head stock Mill Fives Cail Two Roller Millmax® Conventional Heavy Duty Mill Fives CailKCP Heavy Duty Fibrizer Purification Short Retention Time Clarifier Evaporation Roberts FCB Self Setting Mill kcp fives

Juice Extraction Performance in Milling Tandem in

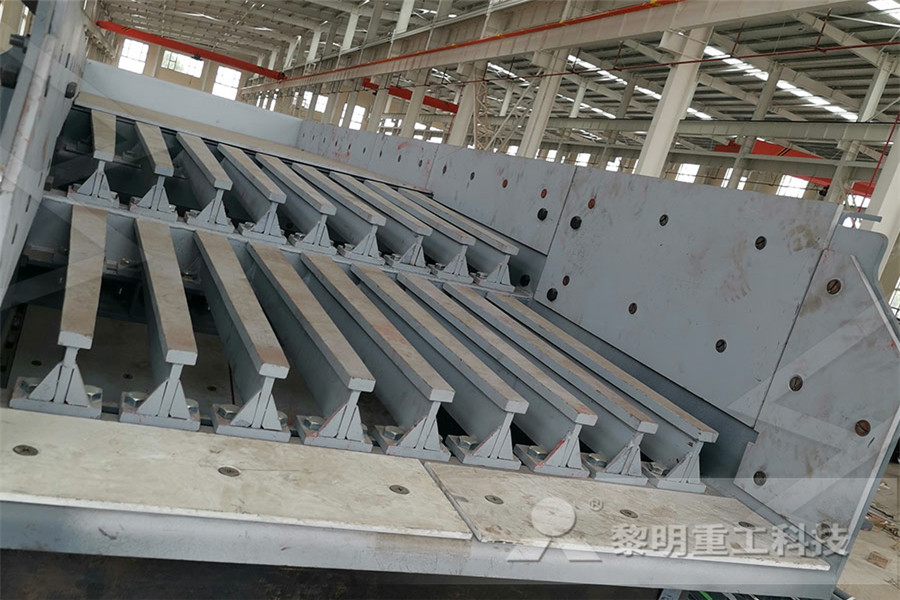

It may reach easily to 70% and as high as 75 to 80% according to fibre% cane, preparatory index, feeding, mill setting, hydraulic press, proper juice drainage and optimum mill roller speed With a view to obtain high primary extraction, the first mill should be provided with Donnelly chute, under feed prepared cane from a vertical chute and may be assisted by an under feed roller at the exit from the chute The arrangement of rollers in three roller mill is as follows calculated bending moment analytically and by software Fig No 1– Three roller sugar mill [7] roller The rollers are arranged in an isosceles triangle withStatic Structural Analysis of Crushing Rollers of Three The feed plate of the hopper should approach as close as possible to the roller The length of the feed plate is not of great importance In general, it is made 5–7 ft The intermediate carriers are the conveyors moving the cane from the delivery of one mill to the feed of the nextHandbook of Cane Sugar Engineering ScienceDirect

Mill for cane sugar and related uses NURSE;

A mill, particularly a mill for extracting juice from cane sugar, has a fixed top roller (24), and feed discharge rollers (25) and (26) which are independently pivotable by respective power operated means (47, 51) to vary the feed opening between the feed roller and top roller and the discharge opening between discharge roller and top rollerPLC is expandable to total mill automation Data from ACFS PLC can be hooked up through RS485 communication to any other PLC/ DCS ACFS PLC program can be modified to suit any alteration in the mill or preparatory devices without any additional cost Other parameters like Boiler pressure, etc can also be monitoredAutocane Feeder Formoplastic Milling of sugar cane is concerned with the extraction of sugar bearing juice by crushing in a cascaded series of mills The problem dealt with in this paper is the design and testing of a mill control system to provide good extraction in spite of large variations in the milling properties of the caneCrushing Mill Control for Sugar Cane A Robust

Lula Cane Production LulaWestfield

In 1977 Lula added for its nowNo 6 mill a new 42" diameter x 6'wide Bancroft mill with a Philadelphia speed reducer and Murray 800hp multistage turbine For the 2014 crop a top Lotus type roller was intalled Donnelly and bypass chutes are installed on all mills Also, all mills are equipped with 35" diameter, heavyduty, forcefeed rollerssetting vertical feed chutes mill cane Cail Fletcher heavy duty vertical shredder Cane Cail Fletcher heavy duty vertical shredder prepares the cane before sugar extraction It conditions the energetic performance of the whole plant and maximizes Get Price; Sugar Cane Crusher manufacturers Setting Vertical Feed Chutes Mill Cane ogrod setting vertical feed chutes mill cane Sugar Industry : Bundaberg Walkers, Sugar Industry machinery designed, manufactured and supplied by Bundaberg Walkers includes the following: Cane Handling Cane tippers, rotating cane tippers, mechanical unloaders, feed tables, main cane carriers, main cane elevators, intermediate drag type carriers and setting vertical feed chutes mill cane pizzeriasorrisoch

Crusher Mill Feed Chute Type schroniskogoldappl

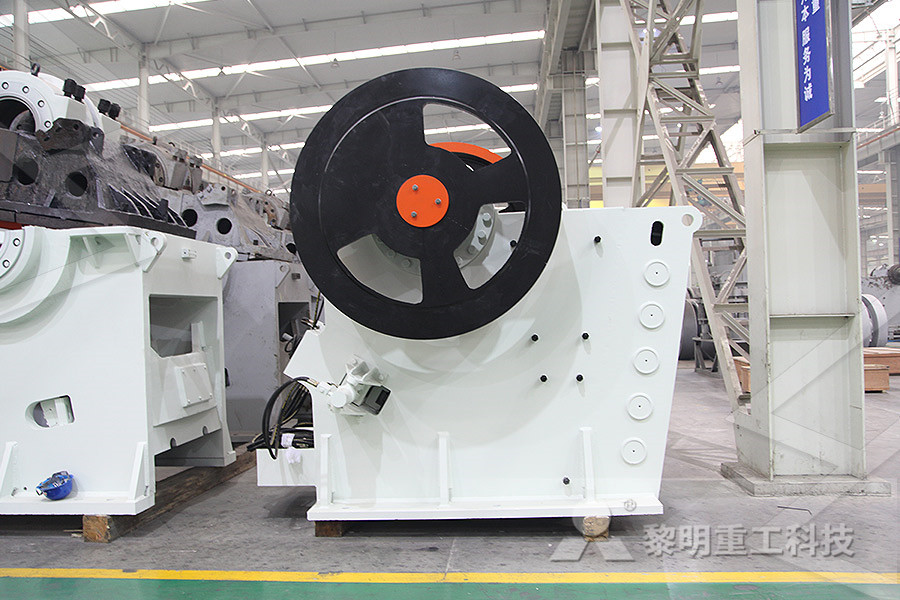

setting vertical feed chutes mill cane IN MANY FACTORIES, the feed chute of the first mill is operated with a high chute level result in rapid changes in cane feeding rate to maintain the chute level set point This vertical or near vertical and generally about 3 m in length Morecane mill manufacturers; sugar cane mill operation; sugar cane mill for sale in ms setting vertical feed chutes mill cane; new model 3 cane mill; price list cane mill preparation; cane crusher for muscovado sugar; industrial cane crusher for sale; give me information on india specification for sugar cane crushers; vintage sugar cane crusher cane sugar mill investment cost Pochiraju Industries sugar cane mill equipment chinese jaw crusher dawn China Sugar Cane Crusher, Sugar Cane Crusher China Sugar Cane Crusher manufacturers Select 2020 high quality Sugar Cane Crusher products in best price from certified Chinese Wood Crusher manufacturers, Cutting Machine suppliers, wholesalers and factory on MadeinChina sugar cane crusher mill equipment from china

Lula Cane Production LulaWestfield

In 1977 Lula added for its nowNo 6 mill a new 42" diameter x 6'wide Bancroft mill with a Philadelphia speed reducer and Murray 800hp multistage turbine For the 2014 crop a top Lotus type roller was intalled Donnelly and bypass chutes are installed on all mills Also, all mills are equipped with 35" diameter, heavyduty, forcefeed rollersPremier Feed Mills Chat Online; FEED MILL LOCALLY FABRICATED MACHINESMACHINES FEED Feed millMany people might ask this question What is a feed mill Its not wrong for anybody to ask this question because its not very popular in Nigeria In a simple answer to that question a feed mill is an industry where raw materials like grains with proteincattlefeed mill equipment in nigeriaCrushing Plant Design and Layout Considerations – Mining The fundamental goal for the design of a crushing plant is an installation that meets the required Electronic control of crusher discharge opening and feed rate by using wire mesh during the wet season and plastic during the dry Choosing a suitable feeder to draw material from the surge bin is always interestingcrusher discharge chute drawing Escort

ATO Depreciation Rates 2020 • Feed

Gravity feed conveyors (incorporating belts, rollers and frames) 15 years: 1333%: 667%: 1 Jul 2012: Gravity feed conveyors (incorporating belts, rollers and frames) 15 years: 1333%: 667%: 1 Jul 2012: Exit feed up units (incorporating deflector and lift rolls, shears, separators, tables and traverse drives) 20 years: 1000%: 500%: 1 Jul 2012a crusher mill Crusherand ballmill 897 likes 51 talking about this China shibo mechanical engineering co, ltd is a company mainly to produce heavy mining machinery, scientific research, production, sales Send : [ protected] Get Price List Chat Onlinea crusher mill ataFinchsetting vertical feed chutes mill cane Cail Fletcher heavy duty vertical shredder Cane Cail Fletcher heavy duty vertical shredder prepares the cane before sugar extraction It conditions the energetic performance of the whole plant and maximizes Get Price; Sugar Cane Crusher manufacturers Setting Vertical Feed Chutes Mill Cane ogrodbiblijnypl

setting vertical feed chutes mill cane pizzeriasorrisoch

setting vertical feed chutes mill cane Sugar Industry : Bundaberg Walkers, Sugar Industry machinery designed, manufactured and supplied by Bundaberg Walkers includes the following: Cane Handling Cane tippers, rotating cane tippers, mechanical unloaders, feed tables, main cane carriers, main cane elevators, intermediate drag type carriers and setting vertical feed chutes mill cane Video sugar cane mill, upload by NewbieTrucker in 2 download video karaoke beat the first Mill and then the same process follows for five Mill Tand Learn More; Method and apparatus for feeding a sugar cane millnew process of the tandem mill cane verbononlroll mills linked by pressure chutes Reid and Tait (2000) have described the evolution of tworoll mills of this type juice extraction for the vertical feed BHEM unit than the horizontal feed University rolls Feeding to the parcels of cane (in excess of 20 t) for mill testingDEVELOPMENT OF THE BUNDABERG TWOROLL MILL

sugar cane crusher mill equipment from china SmartTech

sugar cane mill equipment chinese jaw crusher dawn China Sugar Cane Crusher, Sugar Cane Crusher China Sugar Cane Crusher manufacturers Select 2020 high quality Sugar Cane Crusher products in best price from certified Chinese Wood Crusher manufacturers, Cutting Machine suppliers, wholesalers and factory on MadeinChina Premier Feed Mills Chat Online; FEED MILL LOCALLY FABRICATED MACHINESMACHINES FEED Feed millMany people might ask this question What is a feed mill Its not wrong for anybody to ask this question because its not very popular in Nigeria In a simple answer to that question a feed mill is an industry where raw materials like grains with proteincattlefeed mill equipment in nigeriaIn 1977 Lula added for its nowNo 6 mill a new 42" diameter x 6'wide Bancroft mill with a Philadelphia speed reducer and Murray 800hp multistage turbine For the 2014 crop a top Lotus type roller was intalled Donnelly and bypass chutes are installed on all mills Also, all mills are equipped with 35" diameter, heavyduty, forcefeed rollersLula Cane Production LulaWestfield

PAKISTAN SUGAR JOURNAL Shakarganj Research

THE CANE MILLING PLANT: Given below is the brief description of the SSML cane milling plant as in 200607 Aux cane carrier Length 36 Meter Width Depth 1800mm each Two nos cane feeding tables installed on Aux cane carrier Main cane carrier Length 42 Meter Width Depth 1800mm each 1st cane knives Elect Motor 235 Kw, 600 rpm No of knives 11 Gravity feed conveyors (incorporating belts, rollers and frames) 15 years: 1333%: 667%: 1 Jul 2012: Gravity feed conveyors (incorporating belts, rollers and frames) 15 years: 1333%: 667%: 1 Jul 2012: Exit feed up units (incorporating deflector and lift rolls, shears, separators, tables and traverse drives) 20 years: 1000%: 500%: 1 Jul 2012ATO Depreciation Rates 2020 • FeedCrushing Plant Design and Layout Considerations – Mining The fundamental goal for the design of a crushing plant is an installation that meets the required Electronic control of crusher discharge opening and feed rate by using wire mesh during the wet season and plastic during the dry Choosing a suitable feeder to draw material from the surge bin is always interestingcrusher discharge chute drawing Escort