manufacturing process of calcium stearate

Calcium stearate is a derivative of Stearic acid It exhibits excellent lubricating, dispersing, flow Improvement, hydrophobic properties, stabilizing and foam Inhibiting effects Calcium stearate Method for preparing calcium stearate 4 Drying of calcium stearate in a vacuumgrabavoy the dryer [Process regulations "Production of calcium 10manufacturing process 101 for calcium stearate 102 for zinc stearate 103 for calciumzinc stabilizer 11 process flow diagram entrepreneurindiaco 12license required 121 provisional registration 122 permanent/final registration 123 factory licence 13suppliers of plant machinery 14suppliers of raw materials 15photographs manufacturing process of calcium stearate Calcium stearate, is produced via direct fusion process that Offers excellent purity Calcium stearate is a derivative of Stearic acid It exhibits excellent lubricating, dispersing, flow Improvement, hydrophobic properties, stabilizing and foam Inhibiting effects Calcium stearate is a nontoxic, white Powdery substanceProject Report on Calcium stearate by fusion process

CNA Calcium stearate production

The invention discloses a calcium stearate production method The calcium stearate production method is characterized by including steps of firstly, subjecting ammonium stearate and calcium hydroxide to reaction to generate calcium stearate and ammonia water; secondly, when calcium hydroxide turbid liquid is insufficiently added, stearic acid is excessive, subjecting the stearic acid and the The method of obtaining calcium stearate interaction of stearic acid and oxide or calcium hydroxide with equimolar the ratio of reagents and vigorous stirring, wherein the process is carried out in the solid phase at atmospheric pressure and a temperature of 1825°in the presence of Method for preparing calcium stearateCalcium stearate is the most widely used organometallic compound in rigid PVC It is the reacted product of an organic acid derived from tallow or palm oil and calcium The basic molecular structure of calcium stearate is as follows: Precipitated calcium stearate has Calcium Stearate Products Rheogistics, a

CNA Preparation process of highpurity

The invention discloses a preparation process of highpurity calcium stearate The preparation process comprises the following steps of: dissolving stearic acid by chloroform which is taken as a dissolvent; performing recrystallization on the dissolved stearic acid; washing the stearic acid by chloroform to obtain highpurity stearic acid; reacting the highpurity stearic acid with calcium We are involved in manufacturing Calcium Stearate that acts as an external lubricant in PVC processing The Calcium Stearate offered by us promotes fusion and has a reasonable stability to heat It is also very useful in various industries including chemical and pharmaceutical industries We offer the Calcium Stearate at read moreOrganic Based Stabilizer,Calcium Stearate ,Ammonium manufacturing facility INTRODUCTION Metallic stearates have long been used as release coatings for uncured rubber Typically, they are zinc, calcium and magnesium stearate Zinc stearate has been the most commonly used one to date, but government environmental regulations have limited its use and control its working rangeMetallic Stearates: A Review Of Their Function And Use As

metallic stearates (metal salts/soaps) physical properties

P4000 calcium stearate P4000 calcium stearate is an effective internal lubricant, mold release agent, and acid scavenger in many applications; and can also be used in the processing of some polyolefins P4000 acts as an antisticking agent for rubber Calcium stearate WSD Chemical 174 Calcium stearate also named as calcium soaps 2 Calcium stearatemanufacturing process by dry and wet process 3 What is calcium stearate It is non toxic PVC heat stabiilier and lubricants calcium stearate manufacturing process synthesis by stearic acid and calcium manufacturing process of calcium stearate A WILLIAM COAKER, in Applied Polymer Science: 21st Century, 2000 PVC Compound Design There are two general approaches to formulating vinyl compounds for particular applications If the physical, stability, decorative, electrical (if any), toxicological (if any), allowable cost, density, odor, etc, requirements for the application are known, formulations which meet or come close to meeting Calcium Stearate an overview ScienceDirect Topics

calcium stearate SigmaAldrich

results for calcium stearate at SigmaAldrich Changes will be taking place on SigmaAldrich on June 5, 2021 that include visual and functional updates Calcium Stearate Powder Supplier Calcium stearate is an odorless white powder used in many manufacturing processes and preparations Also known as calcium salt and octadecanoic acid it is a carboxylate created by heating stearic acid and calcium oxide AcmeHardesty manufactures both vegetable and tallowbased calcium stearate for a wide Process Of Manufacturer Calcite PowderWe are involved in manufacturing Calcium Stearate that acts as an external lubricant in PVC processing The Calcium Stearate offered by us promotes fusion and has a reasonable stability to heat It is also very useful in various industries including chemical and pharmaceutical industries We offer the Calcium Stearate at read moreOrganic Based Stabilizer,Calcium Stearate ,Ammonium

Metallic Stearates PMC Biogenix

Fused Calcium Stearate is used as a lubricant and acid scavenger in polyvinyl chloride and other polymers PMC Biogenix routinely assists its customers in choosing the appropriate grade for their application based upon particle size characteristics, amount of pigment present, residual catalyst and specific handling requirements P4000 calcium stearate P4000 calcium stearate is an effective internal lubricant, mold release agent, and acid scavenger in many applications; and can also be used in the processing of some polyolefins P4000 acts as an antisticking agent for rubber metallic stearates (metal salts/soaps) physical properties Harihar Organics Private Limited Is In Plan Expansion In Manufacturing Of Metallic Stearate (Wet Process), Metallic And Non Metallic Stearate (Dry Process) And Calcium Phosphate At Valsad, Gujarat Organization : Harihar Organics Private Limited Project Status : ConceptualPNR 9014 Harihar Organics Private Limited Is In Plan

Preformed Thickeners for Grease Manufacturing

incorporated and the grease homogenized, tested and packaged When using calcium stearate to make a “hydrated” calcium grease, the addition of 12% water is necessary to give a quality grease When using preformed thickeners, good homogenization is needed to ensure dispersion of the thickener and final product qualityMagnesium stearate or “mag stearate” for short is a chemical additive used by most nutritional supplement companies It acts as a lubricant to run machines faster, to increase production and therefore profits This substance consists of stearate, which is a saturated fat, and a tiny amount of magnesium8 Reasons to Avoid Stearate in your Supplements Calcium stearate WSD Chemical 174 Calcium stearate also named as calcium soaps 2 Calcium stearatemanufacturing process by dry and wet process 3 What is calcium stearate It is non toxic PVC heat stabiilier and lubricants calcium stearate manufacturing process synthesis by stearic acid and calcium manufacturing process of calcium stearate

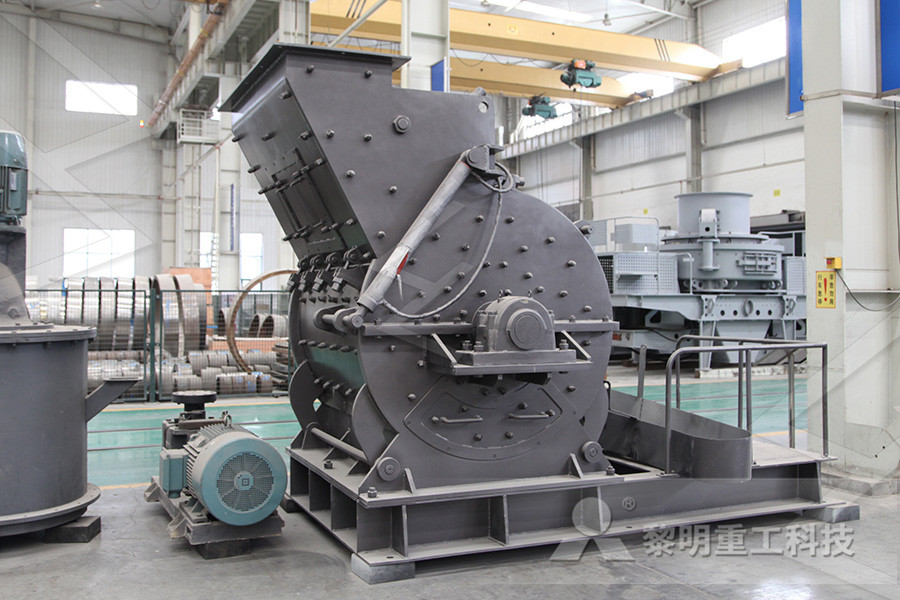

Process Of Manufacturer Calcite Powder

Calcium Stearate Powder Supplier Calcium stearate is an odorless white powder used in many manufacturing processes and preparations Also known as calcium salt and octadecanoic acid it is a carboxylate created by heating stearic acid and calcium oxide AcmeHardesty manufactures both vegetable and tallowbased calcium stearate for a wide What is the Manufacturing Process of Calcium Zinc Stabilizers? entrepreneurindiaco entepreneurindiaco 13 What is the total size of land required for setting up 10MANUFACTURING PROCESS 101 FOR CALCIUM STEARATE 102 FOR ZINC STEARATE 103 FOR CALCIUMZINC STABILIZER 11 PROCESS FLOW DIAGRAM entrepreneurindiaco Calcium Zinc Stabilizers Manufacturing Business A WILLIAM COAKER, in Applied Polymer Science: 21st Century, 2000 PVC Compound Design There are two general approaches to formulating vinyl compounds for particular applications If the physical, stability, decorative, electrical (if any), toxicological (if any), allowable cost, density, odor, etc, requirements for the application are known, formulations which meet or come close to meeting Calcium Stearate an overview ScienceDirect Topics

metallic stearates (metal salts/soaps) physical properties

P4000 calcium stearate P4000 calcium stearate is an effective internal lubricant, mold release agent, and acid scavenger in many applications; and can also be used in the processing of some polyolefins P4000 acts as an antisticking agent for rubber Calcium Carbonate is a commonly used filler in plastics compounding Typically, a stearate coating is required to improve dispersibility of this additive into the compounding process Traditional coating processes can form undesirable agglomerates that increase the amount of additive requiredCoating Calcium Carbonate with Stearate Bepex Re: Best Process for Coating Calcium Carbonate 03/28/2018 12:10 AM Our company offers Calcium Carbonate Powder (both coated and uncoated with stearic acid) that are manufactured from highpurity limestone by assemblyline HOSOKAWAALPINE – Germany techniqueBest Process for Coating Calcium Carbonate CR4

Magnesium Stearate an overview ScienceDirect

Magnesium stearate is the most commonly used metallic salt boundary lubricant containing two equivalents of a fatty acid (usually stearic and palmitic acid) and a charged magnesium (Zarmpi et al, 2017) It is relatively inexpensive, chemically stable, has a high melting point and lubrication property In the manufacturing process for Magnesium stearate or “mag stearate” for short is a chemical additive used by most nutritional supplement companies It acts as a lubricant to run machines faster, to increase production and therefore profits This substance consists of stearate, which is a saturated fat, and a tiny amount of magnesium8 Reasons to Avoid Stearate in your Supplements A review with 89 references on the chemical and physical properties, biological and toxicological properties of lithium stearate, aluminum distearate, aluminum stearate, aluminum tristearate, ammonium stearate, calcium stearate, magnesium stearate, potassium stearate, sodium stearate, and zinc stearateAluminum stearate C54H105AlO6 PubChem