How To Design Attritor Mill Scholman Loodgieters

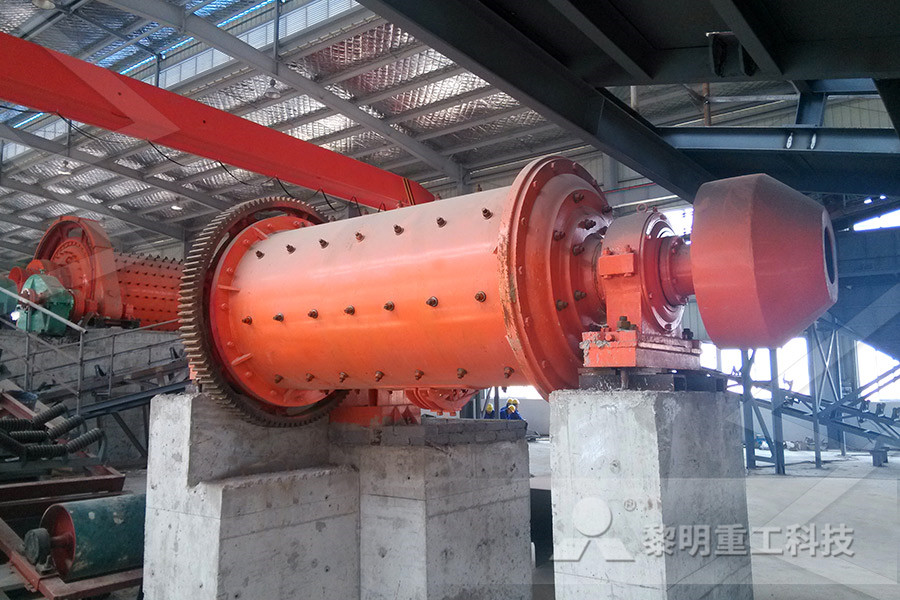

Attritor mill or stirred ball mill as it is commonly known is manufactured by using superior grade of steel Attritor mill is used for grinding and blending process for wet or dry materials Attritor mill performance is great and highly efficient Attritor mill unique design consists of a Detailsattritor mill design Microstructural evolution of Y2O3 and Microstructural evolution of Y 2 O 3 and MgAl 2 O 4 ODS EUROFER steels during their elaboration by mechanical milling and hot isostatic pressingattritor mill design mojursusplAttritor mill or stirred ball mill as it is commonly known is manufactured by using superior grade of steel Attritor mill is used for grinding and blending process for wet or dry materials Attritor mill performance is great and highly efficient Attritor mill unique design consists of a Attritor NITA ENGINEERING

Attritor, How attritor Works, Attritor working, Dry

MIKRONS ® Attritor is used for producing fine homogenous dispersions quickly repeatedly under controlled conditions Used for the manufacture of ceramics , inks, paints,coatings, metal oxides, ferrites, chocolates, chemicals pharmaceuticals The Attritor is often referred to as a agitated ball millAttritor Attritor is used for producing fine homogeneous dispersions quickly repeatedly under controlled conditions Used for the manufacture of ceramics , inks, paints,coatings, metal oxides, ferrite, chocolates, chemicals pharmaceuticals The Attritor is often referred to as a agitated ball millAttritor Milling, Attritor Mill, Attritor For Ceramics This proprietary design eliminates shaft whip and mill vibration, while providing much greater random media motion for improved milling efficiency The mill is designed to accommodate media from 03mm to 10mmATTRITOR GRINDING MILLS AND NEW DEVELOPMENTS

Atritor • Products Industries

The Atritor Cell Mill is a highly efficient mechanical mill with multiple rotors mounted on a vertical shaft The construction is modular, providing great versatility for customised designDesigned for optimum particle size reduction our SmartGrind Attritor Mill reduces particle size upto 35 microns Available in wide range of capacities from laboratory scale to production scale Various chamber configurations available to meet process requirements ranging from 1 L to 300 L and beyondSMARTGRIND ATTRITOR MILLS Renders India Pvt Ltd The motions of grinding media and powder in an attritor canister were studied by means of filming the agitated charge and framebyframe scrutiny of the footage In conjunction with auxiliary experiments, this permitted semiquantitative analysis of the milling action In particular, the mill can be divided into several regions characterized by different balances between direct impacts and Milling dynamics: Part I Attritor dynamics: Results of a

Laboratory Attritor, Attritors

MIKRONS® Lab Attritor has been designed to allow easy removal of the grinding chamber from the mill The motor is controlled vide a variable frequency drive controller The MIKRONS® Lab model Attritors are versatile, reliable laboratory machine designed to meet all the lab grinding needsAttritor mill or stirred ball mill as it is commonly known is manufactured by using superior grade of steel Attritor mill is used for grinding and blending process for wet or dry materials Attritor mill performance is great and highly efficient Attritor mill unique design consists of a DetailsHow To Design Attritor Mill Scholman LoodgietersAttritor mill or stirred ball mill as it is commonly known is manufactured by using superior grade of steel Attritor mill is used for grinding and blending process for wet or dry materials Attritor mill performance is great and highly efficient Attritor mill unique design consists of a Attritor NITA ENGINEERING

Union Process Attritor Mills

The Attritor is often referred to generically as an "internally agitated high energy media (ball) mill" Attritors work ten times faster than ball mills, and are advantageous because they offer simple operation, rugged construction, and a compact design Advantages of Using an Attritor Description GTEK Attritor Mill or Stirred Ball Mill is a grinding mill containing internally agitated media It is a simple and effective method of grinding and dispersing fine and homogenous material quickly and repeatedly GTEK laboratory size Attritor Mill or Stirred Ball Mill is designed with variable speed drive for different RPM selections The Attritor Ball Mill can operate with wet Attritor MillStirred Ball Mill GTEKAttritor Attritor is used for producing fine homogeneous dispersions quickly repeatedly under controlled conditions Used for the manufacture of ceramics , inks, paints,coatings, metal oxides, ferrite, chocolates, chemicals pharmaceuticals The Attritor is often referred to as a agitated ball millAttritor Milling, Attritor Mill, Attritor For Ceramics

Laboratory Attritor, Attritors

MIKRONS ® Attritor is used for producing fine homogenous dispersions quickly repeatedly under controlled conditions Used for the manufacture of ceramics , inks, paints,coatings, metal oxides, ferrites, chocolates, chemicals pharmaceuticals The Attritor is often referred to as a agitated ball mill Agitator Bead Mill Attritor: MIKRONS® ATTRITORS are available in broad ranges from traditional attrition mill type to the latest wet dry grinding type, circulation type attritorsAgitator Bead Mill Attritor The present model focuses on experiments using an attritor mill, model 01HD by Union Process In this mill, milling balls are agitated by a steel impeller rotating at a designated speed In the experiments, the impeller was set to rotate at 400 rpm The attritor mill contains a Discrete element model for an attritor mill with

Milling dynamics: Part I Attritor dynamics: Results of a

The motions of grinding media and powder in an attritor canister were studied by means of filming the agitated charge and framebyframe scrutiny of the footage In conjunction with auxiliary experiments, this permitted semiquantitative analysis of the milling action In particular, the mill can be divided into several regions characterized by different balances between direct impacts and Attritor mill geometry with the twodifferent impeller designs: a) SD1 original design (impeller with long arms) with a gap between arm and inner wall of 125 mm b) Modified impeller design (impeller with shorter arms) with a gap between arm and inner wall of 25 mmInvestigating grinding media dynamics inside a Description GTEK Attritor Mill or Stirred Ball Mill is a grinding mill containing internally agitated media It is a simple and effective method of grinding and dispersing fine and homogenous material quickly and repeatedly GTEK laboratory size Attritor Mill or Stirred Ball Mill is designed with variable speed drive for different RPM selections The Attritor Ball Mill can operate with wet Attritor MillStirred Ball Mill GTEK

SMARTGRIND ATTRITOR MILLS Renders India Pvt Ltd

An attritor mill has a specific advantage over other conventional milling equipment and thus are very popular among the industry owners and process managers Our flawless designed and manufactured advanced featured SmartGrind Attritors are thus employed in numerous applications in various industries across the globe in an attritor Powder circulation within an operating mill was also investigated Based on the results and the accompanying analysis, concepts for improved attritor design are presented I INTRODUCTION MECHANICAL alloying (MA) is a technique for producing powders manifesting intriguing propertiesMilling dynamics: Part I Attritor dynamics: Results of a Find here online price details of companies selling Attrition Mills Get info of suppliers, manufacturers, exporters, traders of Attrition Mills for buying in IndiaAttrition Mills at Best Price in India

Attritor Mill Manufacturers, Attritor Mill Suppliers

Find here directory of top attritor mill manufacturers, attritor mill suppliers and exporters from India These attritor mill companies offer top quality products at affordable pricesThe motions of grinding media and powder in an attritor canister were studied by means of filming the agitated charge and framebyframe scrutiny of the footage In conjunction with auxiliary experiments, this permitted semiquantitative analysis of the milling action In particular, the mill can be divided into several regions characterized by different balances between direct impacts and Milling dynamics: Part I Attritor dynamics: Results of a Attritor SF Attritor is used for producing fine homogenous dispersons quickly repeatedly under controlled conditions Used for the manufacture of ceramics , inks, paints,coatings, metal oxides, ferrites, chocolates, chemicals pharmaceuticals The Attritor is often referred to as a agitated ball millAttritor, Attritor Manufacturers India, Sf Engineering Works

Lab Attritor is designed for limestone grinding

Whereas CL Series production Attritors provide large, continuous production with throughputs in the tons per hour, the CL5 Lab Attritor will process in the range of 200500 pounds of limestone per hour The mill is equipped with a variable frequency drive (VFD) and a 15 horsepower inverter duty motor The CL5 uses 25 gallons of grinding media Attritor mill geometry with the twodifferent impeller designs: a) SD1 original design (impeller with long arms) with a gap between arm and inner wall of 125 mm b) Modified impeller design (impeller with shorter arms) with a gap between arm and inner wall of 25 mmInvestigating grinding media dynamics inside a vertical Bead Mill Design highlights: Grinding chamber: horizontal position with cooling jacket Agitator discs: Specially shaped agitator discs provide good Bead mill, sand mill, Perl mill, dyno mill, small media