Process Of Operating A Cement Mill moribito

Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 176c in a cement kiln in this process, the chemical bonds of the raw materials are broken down and then they are Cement Manufacturing Process Phases Production of cement completes after passing of raw materials from the following six phases These are; Raw material extraction/ Quarry; Grinding, Proportioning and Blending; Preheater Phase; Kiln Phase; Cooling and Final Grinding; Packing Cement Manufacturing Process Phases Flow Chart The cement flows from the inlet to the outlet of the mill (a rotating chamber), being first ground with 60 mm then 30 mm diameter steel balls The first grinding breaks up the material and the second grinds it to a fine powder The amount of grinding is Cement manufacturing process new SlideShare

Cement Mill for sale, Cement Mill Process, Cement

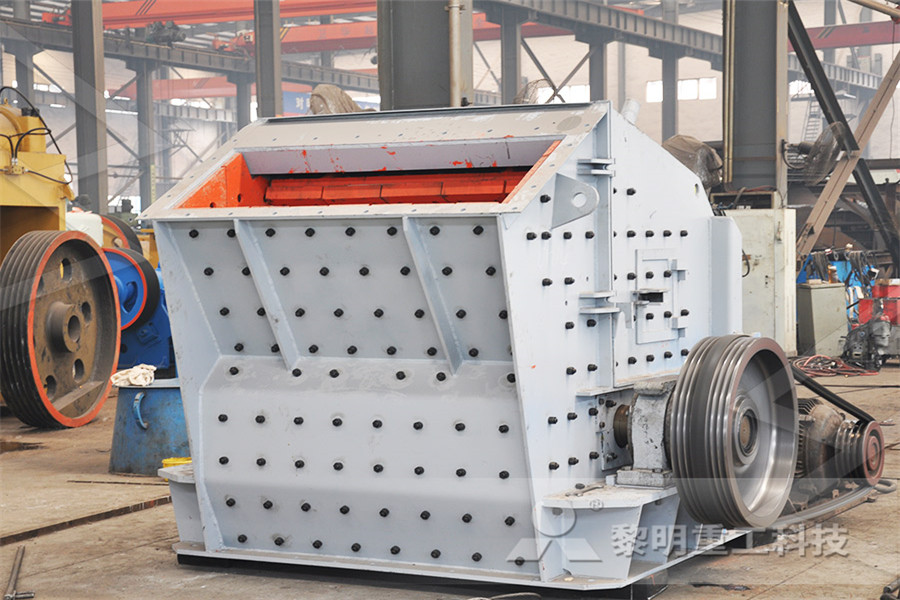

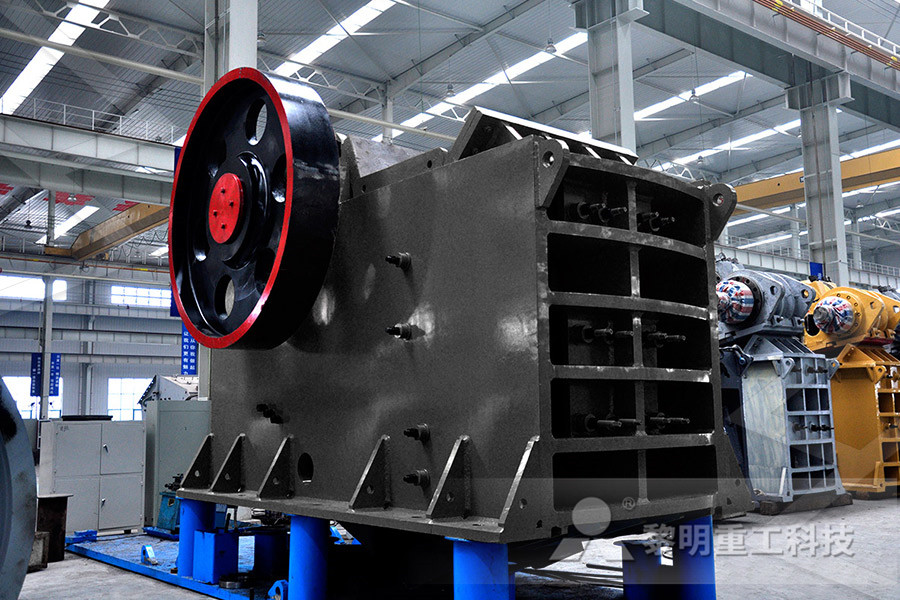

A cement mill is the equipment that used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement Most cement is currently ground in ball mills Cement clinker is usually ground using a cement ball mill This is essentially a large rotating drum containing grinding media normally steel ballsOur Cement Mill Optimizer system, is a parallel intelligent solution that acts as an autopilot for the cement grinding circuit It optimizes the cement quality and increases the overall production by keeping the cement product fineness closer to the ideal targets or in other words keeping a low standard deviation of the final product particles volumeES Processing Cement IndustryCement Grinding Process Ball Mill Machine From China Professional Manufactor High Efficient Dry Process Cement Ball Mill High Quanlity Good Performance Dry Ball Mill Cement Ball Mill Professional Manufacturer Ball Mill for Cement Making Plant Air Swept Coal Grinding Ball Mill for Cement China Cement Ball Mill for Dry Process China

Cement kiln Wikipedia

A typical process of manufacture consists of three stages: grinding a mixture of limestone and clay or shale to make a fine "rawmix" (see Rawmill); heating the rawmix to sintering temperature (up to 1450 °C) in a cement kiln; grinding the resulting clinker to make cement In cement production process, about 26% of the total electrical power is used in grinding the raw materials During grinding process, the energy obtained from the rotary burner is consumed In this study, the first and second law analysis of a raw mill is performed and certain measures are implemented in an existing raw mill in a cement factory in Reducing energy consumption of a raw mill in cement Vertical grinding mill is the main grinding equipment for the newtype dry cement raw meal production, raw material grinding process in cement industries accounts for approximately 50–60 % of the total energy consumption The dynamic characteristics of the variables in the raw material vertical mill grinding process are strongly coupled, nonlinear, Modeling Based on the Extreme Learning Machine for

The cement mill

Cement manufacturing brief description of a cement mill Cement clinker is usually ground using a ball mill This is essentially a large rotating drum containing grinding media normally steel balls As the drum rotates, the motion of the balls crushes the clinker The drum Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kilnThe Cement Manufacturing Process Thermo Fisher into Cement Mill for fine size reduction Gypsum is added to control setting time of cement Circuit Types : Open circuit Ball Mill , Closed circuit Ball Mill , Roller Press with Ball Mill,VRM with Ball Mill Depending on final Cement requirements Flyash or Slag is added along with Crushed Clinker Process Overview Different Type of Process Cement Process Chemistry Mill (Grinding) Manmade

Surya Gold Cement Manufacturing Cement Grinding Process

The mill is a large revolving cylinder containing steel balls that is driven by a motor The finished cement is ground so fine that it can pass through a sieve that will hold water THE CEMENT GRINDING PROCESS The Cement Process What is Cement? A powder of alumina, silica, lime, iron oxide, and magnesium oxide burned together in a kiln and finely pulverized and used as an ingredient of mortar and concrete The adhesive or Glue that holds concrete together Concrete: a hard strong building material made by mixing a cementing material (as portland cement) and a mineral aggregate (as sand and Cement Process Overview Mill (Grinding) Manmade Cement Manufacturing Process Cement Manufacturing Process Cement Manufacturing Process Cement is a material which is used to bind other materials together Binding means it has an effect of gluing the substances together due to cohesive and adhesive action and then hardens and sets in order to become permanent Cement is usually not used on Cement Manufacturing Process Chemical Engineering World

How Is Cement Produced in Cement Plants Cement Making

The making process of portland cement in the modern industry can be divided into the wet process, dry process, and semidry process Nowadays, the dry process is the most popular cement making process which is widely adopted by cement plants all over the world for its great advantages in energy saving and environmental protection Why Every Component of a Cement Mill Counts in the Production Process Share This Article: Operators of cement plants worldwide face the challenge to create their systems more efficient and reliable Even though the production and consumption of this material is quite stable in Europe, there is a continuously growing demand in Africa, North Why Every Component of a Cement Mill Counts in the Dehydration of the gypsum added to the cement In the grinding process heat will be generated and the cement will be heated up The temperature of the cement leaving the mill will be dependant on the temperature of the materials (especially the clinker) fed to the mill and to features of the mill and the grinding processCement grinding Vertical roller mills versus ball mills

Cement KIMA Process Control

LEADING TECHNOLOGY IN BALL MILL CONTROL With MILLMASTER KIMA Process Control offers the most robust, open and easy to handle Advanced Control System in the Cement Industry Since 1996 this ‘AutoPilot’ system was installed in hundreds of cement plants to operate mills fully autonomously Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 °C in a cement kilnThe Cement Manufacturing Process Thermo Fisher The Cement Process What is Cement? A powder of alumina, silica, lime, iron oxide, and magnesium oxide burned together in a kiln and finely pulverized and used as an ingredient of mortar and concrete The adhesive or Glue that holds concrete together Concrete: a hard strong building material made by mixing a cementing material (as portland cement) and a mineral aggregate (as sand and Cement Process Overview Mill (Grinding) Manmade

Manufacturing Process – Continental Cement

Cement is made from common materials such as limestone, clay, silica, and iron ore that are blended together Click on the circles above and tour Continental Cement’s Hannibal plant to view the cement making process For a more detailed description of the cement manufacturing process, visit Portland Cement Association’s presentation Abstract: It is known that the variable is strong coupling, nonlinear, multivariable and large timedelay dynamic characteristics in the raw cement vertical mill grinding process Against the problem which is difficult to establish accurate mathematical model, this paper establishes a production index prediction model of vertical mill raw meal grinding process by using echo state network and Modelling of the vertical raw cement mill grinding process Cement grinding is the last process of cement production, it is to mix cement clinker and a small amount of gypsum, and then grind the mixture to a certain fineness, that is cement You may also interest in the ball mill product price , lime ball mill , quartz ball mill Cement Ball Mill JXSC Machine

Cement Mill Great Wall

The cement ball mill is mainly used to grind cement clinker in cement production process, and it also applies to grinding various ores and other grindable materials in industrial and mining enterprises such as metallurgical plant, chemical plant and power plant and so on Our company has more than 40year experience on the manufacture of cement ball mill, the quality of our product takes a Dehydration of the gypsum added to the cement In the grinding process heat will be generated and the cement will be heated up The temperature of the cement leaving the mill will be dependant on the temperature of the materials (especially the clinker) fed to the mill and to features of the mill and the grinding processCement grinding Vertical roller mills versus ball mills Abstract: Cement is the basic material used for construction activities The Cement manufacturing process mainly can be divided in to ten stages From limestone loading to dispatching of cement various hazards takes place which causes harm The purpose of this project to minimize the riskRisk Assessment in Cement Manufacturing Process

Cement KIMA Process Control

LEADING TECHNOLOGY IN BALL MILL CONTROL With MILLMASTER KIMA Process Control offers the most robust, open and easy to handle Advanced Control System in the Cement Industry Since 1996 this ‘AutoPilot’ system was installed in hundreds of cement plants to operate mills fully autonomously Mining Process Flow Chart Prism Cement Limited: Investor Update Feb 2014 remnimegadynedlyamelynicivalycovyhstankov pdf MinAS Demoproject En gbsp47 1s20S26807main 15 General Equipment Description of Ball Mill Cement mill (Ball Mill1 cement mill ppt Mill (Grinding) Cement