Molybdenum processing Britannica

Molybdenum processing, preparation of the ore for use in various products Molybdenum (Mo) is a white platinumlike metal with a melting point of 2,610 °C (4,730 °F) In its pure state, it is tough and ductile and is characterized by moderate hardness, high thermal conductivity, high resistance to corrosion, and a low expansion coefficient Lowgrade oxide ore leaching with sulfuric acid to extract pure molybdenum trioxide exchange or extraction from solution using ion In addition, molybdenum smelting methods, as well as lime calcination, leaching nitrate, sodium hypochlorite leaching, electrooxidation leaching methodMolybdenum ore processing technologyMolybdenum processing Milling Ball or rod mills crush and grind the mined ore to fine particles that may be only microns (103 mm) in diameter, releasing molybdenite from the gangue (worthless rock)Molybdenum Processing IMOA

Molybdenum Ore Processing by Flotation 911

The Molybdenum Process Flowsheet In the crushing department, which is designed for 8hour per day operation, a heavy duty apron feeder, with plenty of length for picking purposes, starts the ore on its way The crusher operator with his assistant can The molybdenum ore processing production process mainly includes three processes of crushing, grinding and beneficiationMolybdenum Ore Processing dewomachineThe mining of molybdenum ore includes open cast pit technology and the underground block caving technique Molybdenum processing includes several processes, such as flotation, roasting and upgradingMolybdenum: mining and processingMetalpedia

molybdenum ore processing method

Jan 05, 2021 Molybdenum ore introduction: The molybdenum ore processing production process mainly includes three processes of crushing, grinding and beneficiationIn the process of crushing, the threestage closedcircuit crushing is a modern crushing method suitable for molybdenum ore, which can complete the work of ore crushing and partial dissociation, thereby improving the subsequent If the ore is located deep underground, underground block caving technology is adopted Large pieces of ore are cut from the bottom and collapse under their own weight, and the resulting ore is transferred to the ground for the processing Molybdenum Processing 1 GrindingHow Is Molybdenum Mined and Processed? The beneficiation processing of molybdenum ore is mainly performed by flotation, and the recovered molybdenum mineral is molybdenite (MoS2) Sometimes in order to improve the quality of molybdenum concentrate and remove impurities, the concentrated molybdenite would be subjected to a further step of chemical beneficiation processingMineral Processing 101 : Molybdenum Ore

Molybdenum Mining IMOA

Molybdenite can occur as the sole mineralization in an ore body, but is often associated with the sulphide minerals of other metals, notably copper The Mo content of viable ore bodies ranges between 001 and 025% Depending upon the minerals contained in the ore body and their quality, molybdenum mines are grouped in three classes: Molybdenum processing, preparation of the ore for use in various products Molybdenum (Mo) is a white platinumlike metal with a melting point of 2,610 °C (4,730 °F) In its pure state, it is tough and ductile and is characterized by moderate hardness, high thermal conductivity, high resistance to corrosion, and a low expansion coefficientMolybdenum processing BritannicaMolybdenum ore introduction: The molybdenum ore processing production process mainly includes three processes of crushing, grinding and beneficiationIn the process of crushing, the threestage closedcircuit crushing is a modern crushing method suitable for molybdenum ore, which can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding Molybdenum ore processing Dewo Machinery

Molybdenum Ore Processing dewomachine

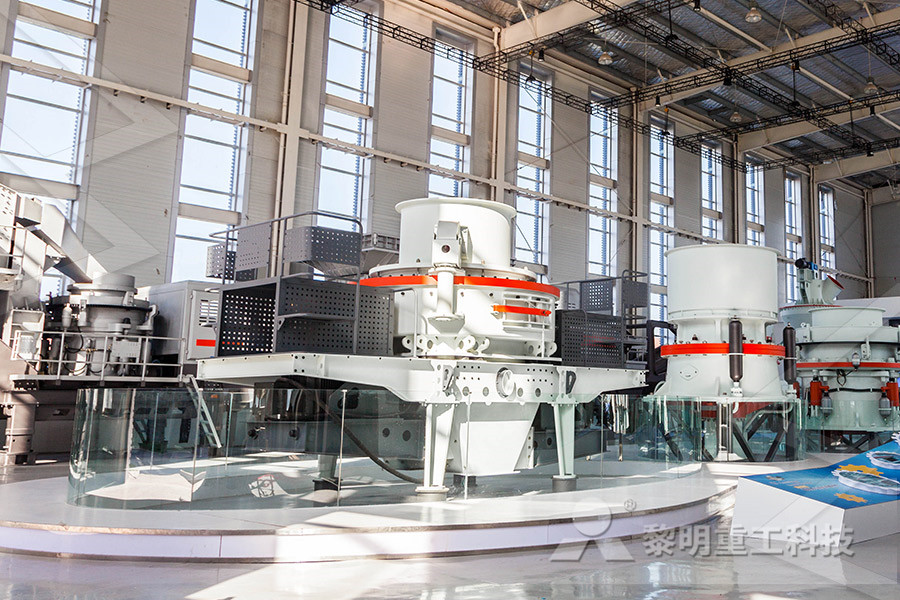

The molybdenum ore processing production process mainly includes three processes of crushing, grinding and beneficiation Molybdenum ore processing technology Details Category: Molybdenum knowledge Published on 29 July 2014 Written by ling Hits: 289 On the current industrial production of molybdenum, mainly using molybdenite concentrates for smelting, roasting oxidation, extraction of pure molybdenum trioxide, molybdenum metal powder reduction roasting three linksMolybdenum ore processing technology Molybdenum processing plant With high electrical conductivity and good thermal conductivity, molybdenum and its alloys have extensive applications and good prospects in metallurgy, agriculture, electrical, chemical, environmental protection, aerospace department, etc The molybdenum ore are transport to the vibrating feeder by dumper Molybdenum ore processing line

Mineral Processing 101 : Molybdenum Ore Beneficiation

Overview of Molybdenum Ore Beneficiation The beneficiation processing of molybdenum ore is mainly performed by flotation, and the recovered molybdenum mineral is molybdenite(MoS2) Sometimes in order to improve the quality of molybdenum concentrate and remove impurities, the concentrated molybdenite would be subjected to a further step of chemical beneficiation processing Molybdenum metal is a very important metal, which is known as war metal With high strength, high melting point, corrosion resistance, wearresisting, so it is widely used in industry Technical Process The processing technology of molybdenum ore mainly includes three processes: crushing, grinding and ore dressingMolybdenum ore processing technologyBAILING® MachineryMolybdenum was discovered by Carl Wilhelm Scheele in 1778, and was isolated and named by Peter Jacob Hjelm in 1781 The most important ore source of molybdenum is the mineral molybdenite; a minor amount is recovered from the mineral wulfenite Molybdenum commonly is recovered as a byproduct or coproduct from copper miningMolybdenum Processing Equipment, Process Flow, Cases

How Is Molybdenum Mined and Processed? Refractory

How Is Molybdenum Mined And Processed? Molybdenum is a silverwhite metal with an atomic number of 42, a density of 102 g / cm³, a melting point of 2610 ° C, and a boiling point of 5560 ° C Molybdenum mining and processing technology have been improving since 1916, when Climax molybdenum was first mined near Leadville, Colo In this article, we will talk about how is molybdenum mined and processing1 In 1993, one mine extracted molybdenum ore, and nine mines recovered molybdenum as a byproduct Two plants converted molybdenite concentrate to molybdic oxide, which was used to produced ferromolybdenum, metal powder, and other molybdenum compounds2 Exhibit 1 presents the names and locations of molybdenum mines and processing MOLYBDENUM, FERROMOLYBDENUM, AND The molybdenum ore processing production process mainly includes three processes of crushing, grinding and beneficiationMolybdenum Ore Processing dewomachine

Molybdenum ore processing line

Molybdenum processing plant With high electrical conductivity and good thermal conductivity, molybdenum and its alloys have extensive applications and good prospects in metallurgy, agriculture, electrical, chemical, environmental protection, aerospace department, etc The molybdenum ore are transport to the vibrating feeder by dumper Molybdenum ore processing – 2021 Henan Dewo Machinery Jan 05, 2021 Molybdenum ore introduction: The molybdenum ore processing production process mainly includes three processes of crushing, grinding and beneficiationIn the process of crushing, the threestage closedcircuit crushing is a modern crushing method suitable for molybdenum ore, which can complete the work of ore crushing molybdenum ore processing method Molybdenum metal is a very important metal, which is known as war metal With high strength, high melting point, corrosion resistance, wearresisting, so it is widely used in industry Technical Process The processing technology of molybdenum ore mainly includes three processes: crushing, grinding and ore dressingMolybdenum ore processing technologyBAILING®

Molybdenum Processing Equipment, Process Flow,

Molybdenum was discovered by Carl Wilhelm Scheele in 1778, and was isolated and named by Peter Jacob Hjelm in 1781 The most important ore source of molybdenum is the mineral molybdenite; a minor amount is recovered from the mineral wulfenite Molybdenum commonly is recovered as a byproduct or coproduct from copper miningMolybdenum is an essential trace element for human animal and plant health and has played an important part in the evolution of life on earth protected Iron Ore Mining And Processing Equipment Machine Type Of Iron Ore Fines/Mineral Processing And Find Complete Details about Iron Ore Inquiry Onlinemolybdenum ore processing plant mojursusplMolybdenum ore processing and equipment Molybdenum ore rough crushed by Jaw crusher , then grinded into a suitable particles transport by conveyor to storage 1Feeded by feeder into ball mill for grinding 2The product after ball mill is transported to classifier , according the different gravity and size , wash and classify the minerals Molybdenum Dressing Production Line Yantai

Flotation technology of refractory lowgrade

Lowgrade refractory molybdenum ore can obtain good separation indexes by reasonable mineral processing technology In this experiment, the molybdenum separation and enrichment method brings a new way to the development and application of the refractory molybdenum ore with high oxidation rate, low grade, easy to slime in ChinaWikizero Ore Molybdenum Mining And Ore Processing Plant Equatorial Guinea Ore is natural rock or sediment that contains one or more valuable minerals typically metals that can be mined treated and sold at a profitOre is extracted from the earth through mining and treated or refined often via smelting to extract the valuable metals or mineralsMolybdenum Mining And Ore Processing Plant processing1 In 1993, one mine extracted molybdenum ore, and nine mines recovered molybdenum as a byproduct Two plants converted molybdenite concentrate to molybdic oxide, which was used to produced ferromolybdenum, metal powder, and other molybdenum compounds2 Exhibit 1 presents the names and locations of molybdenum mines and processing MOLYBDENUM, FERROMOLYBDENUM, AND