image of ball mill used in thermal power plant

image of ball mill used in thermal power plant Thermal power plants coal pulverising in boilers aug , mainly there are three types of pulverizer used in industry the slow speed mills like ball tube mills, the medium speed mills like bowl, ball and race, roller mills fall in this egory, and the third type is the high speed impact mill Low 10 to 20 RPM Ball tube mills (16 rpm in Vindhyachal) Medium High 40 to 70 RPM 900 to 1000 RPM Bowl Mill, MPS Impact or Mill, Ball and Hammer Race mill Mill Beater Mill or Fan Mill TYPES OF MILL Tube or ball mills: These are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder If theCoal Mills in Thermal Power Plant Mill (Grinding The four most common types of coal pulverizers are: BallTube Mills This type of mill consists of a rotating tube filled with cast alloy balls Coal is introduced through two hollow trunnions on each side of the tube As the tube rotates, the balls tumble onto the coal, crushing and pulverizing it Impact MillsCoal Pulverizer Pall

COAL BASED THERMAL POWER PLANTS: COAL MILLS

Ball tube mills are either pressurized or suction type In the pressurized type, the hot primary air is used for drying the coal and to transport the milled coal to the furnace In this type, leakage in the mill area is highIn the suction type, the exhauster is used for lifting the milled coal from the pulverizer to the furnace through a cycloneFor example, the are used to pulverize coal for combustion in the steamgenerating furnaces of fossil fuel power plantsTypes of Pulverisers: Ball and Tube mills; Ring and Ball mills; MPS; Ball mill; Demolition ii) Dryers: they are used in order to remove the excess moisture from coal Thermal Power Plant Working Indian Power SectorIn coalfired power stations, the raw feed coal from the coal storage area is first crushed into small pieces (in the crusher department) and then conveyed to the coal feed hoppers at the boilers The coal is next pulverized into a very fine powder The pulverizes may be Ball/Tube Mills, Vertical Mills or EMillsThermal Power Plants Shri Balaji

Coal mill pulverizer in thermal power plants

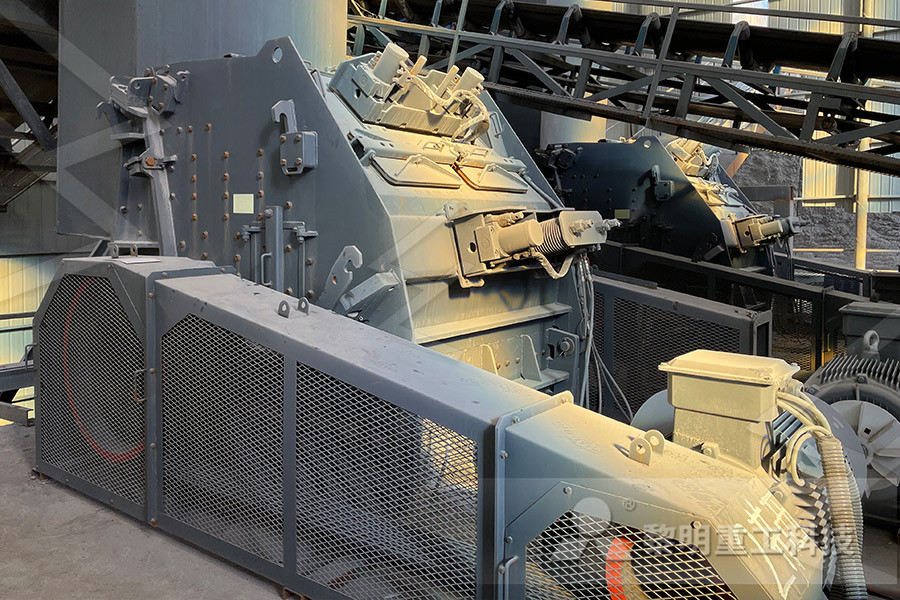

2Coal pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill The pulverized coal and air mixture is then transport to the boiler burner Understanding of coal mill system21 Types of coal mills Coal mills are categorized based on the speed into three categories namely, low speed, medium speed, and high speed mills Low speed and medium speed mills are the most popular ones in a coal fired thermal power plant and are discussed below 211 Operation of low speed millsReview of control and fault diagnosis methods 2 The coal mill The work presented in this chapter is based on a MKM33 ball mill used at Rybnik Unit 4 (rated capacity 220 MW) The mill is one of six mills supplying the 650k (steam production of 650 t/h) boiler However, the proposed method in this chapter is so generic that it can be applied to other types of coal millsDetection of Malfunctions and Abnormal Working

ball coal mills power plants skladterlickocz

Coal Mills in thermal power plant Mill (Grinding Low 10 to 20 RPM Ball tube mills (16 rpm in Vindhyachal) Medium High 40 to 70 RPM 900 to 1000 RPM Bowl Mill, MPS Impact or Mill, Ball and Hammer Race mill Mill Beater Mill or Fan Mill TYPES OF MILL Tube or ball mills: These are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder If theMining comminutioncrusher ball mill and advanced Consider the flow that an ore body steel ball mills steel ball mills jmt maintenance costs are lower than with any other type of will find it is designed and constructed according to heavy duty specifi ionsget price Maintenance of ball mill in thermal power plant pdf Ball mill Wikipedia A ball ball mill types and specification ball mill thermal power ball tube mills for power station gmecrusher riley ball tube mills for coal fired power plants power station ball mill Thermal Power Plant Working sation Riley Ball Tube Mills For Coal Fired Power Plants

COAL BASED THERMAL POWER PLANTS: COAL MILLS FOR THERMAL

Ball tube mills are either pressurized or suction type In the pressurized type, the hot primary air is used for drying the coal and to transport the milled coal to the furnace In this type, leakage in the mill area is highIn the suction type, the exhauster is used for lifting the milled coal from the pulverizer to the furnace through a cycloneIn coalfired power stations, the raw feed coal from the coal storage area is first crushed into small pieces (in the crusher department) and then conveyed to the coal feed hoppers at the boilers The coal is next pulverized into a very fine powder The pulverizes may be Ball/Tube Mills, Vertical Mills or EMillsThermal Power Plants Shri Balaji locations in coalfired power plants where bearings are typically used, such as in beater wheel mills, tube and bowl mills, and air preheaters PRODUCTS Everything from one source: From Xlife to service Economical systems in thermal power plants require reliable components SchaefflerBearing Solutions and Services for Thermal Power Plants

Determining Optimum Productivity of a Ball Drum Mill When

Ball drum mills (BDM) are one of the main types of coalgrinding equipment in Russia A significant drawback of BDM is high power consumption (a significant part of the TPP’s own needs) With a huge scale of production, reducing these costs even by a few percent gives a significant economic effect The problem of minimizing the specific energy consumption for grinding and transporting Azean The Amer 9 plant utilizes both direct and indirect cofiring configurations The plant cofires biomass pellets up to a maximum of 1200 kt yr −1, generating 27% by heat through two modified coal mills Only woodbased fuel has been used since 2006, due to reduced subsidies for agricultural byproductsCoal Mill an overview ScienceDirect Topics Mainly there are three types of pulverizer used in industry: The slow speed mills like ball tube mills, the medium speed mills like bowl, ball and race, roller mills fall in this category, and the third type is the high speed impact millThe slow speed and medium speed mills are selected for coals ranging from subbituminous to anthraciteTHERMAL POWER PLANTS: COAL PULVERISING IN BOILERS

Review of control and fault diagnosis methods applied to

Understanding of coal mill system21 Types of coal mills Coal mills are categorized based on the speed into three categories namely, low speed, medium speed, and high speed mills Low speed and medium speed mills are the most popular ones in a coal fired thermal power plant and are discussed below 211 Operation of low speed mills Coal Mills in thermal power plant Mill (Grinding Low 10 to 20 RPM Ball tube mills (16 rpm in Vindhyachal) Medium High 40 to 70 RPM 900 to 1000 RPM Bowl Mill, MPS Impact or Mill, Ball and Hammer Race mill Mill Beater Mill or Fan Mill TYPES OF MILL Tube or ball mills: These are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder If theball coal mills power plants skladterlickoczbowl mill coal based thermal power plant video Bowl mill power plant ball mill is in power plants bowl and race mill for coal pulveriser ring is stationary ringroll bowlmill and ballrace mills comprise the majority of coal pulveriers currently in service at power generating faciliti figure shows a cutaway of a ringroll type coal pulverier in this design the grinding rolls are stationary while what are the applications of ball mills in coal fired

coal mill model in thermal power plant cafedumilieuch

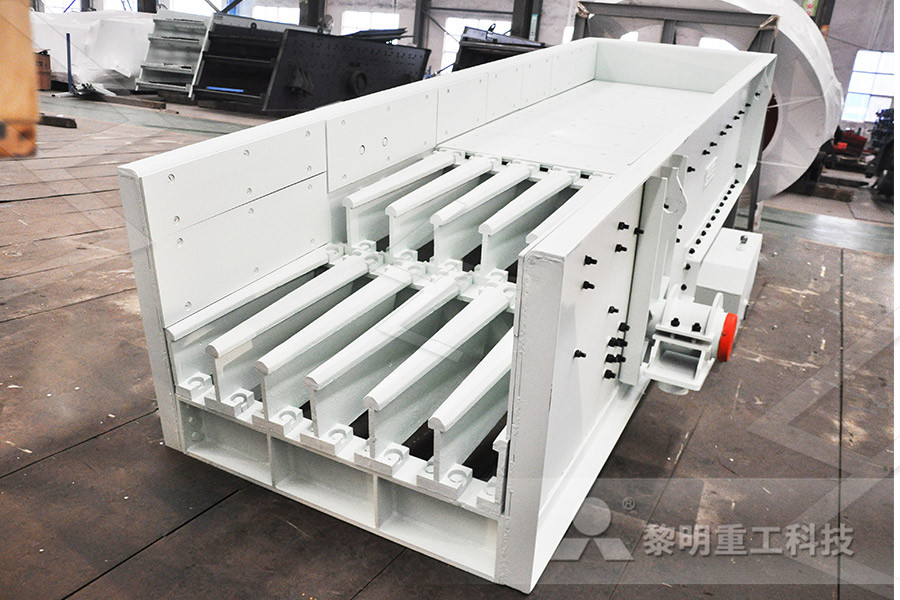

processes of coal mill in thermal power plant millmakercom Dec 19, 2008 EHS issues associated with thermal power plants, which occur during the site selection and plant design processes in order to maximize the range of options as the fuel (eg, coal, fuel oil, natural gas, or biomass), the type and design of the thermal power plants and other plants include coal mill Bowl mills of slow and medium speed (for both pressurized suction environment) for coal fired thermal stations with capacity from 10 T /Hr to 120 T/ Hr suitable upto 1000 MW thermal power stations Ball Tube mills for pulverizing lowgrade coal with high ash content from 30 T/ Hr to 110 T/ Hr catering to 110 MW to 500 MW thermal powerABOUT US BHELball tube coal pulverizer Newest Crusher Grinding Mill ring and ball mill pulverizer Quartz Crusher, Quartz Crushing The four most common types of coal pulverizers are: BallTube Mills This type of Tube And Ball Mill Coal Pulverizer Ppt

Coal Mill an overview ScienceDirect Topics

The Amer 9 plant utilizes both direct and indirect cofiring configurations The plant cofires biomass pellets up to a maximum of 1200 kt yr −1, generating 27% by heat through two modified coal mills Only woodbased fuel has been used since 2006, due to reduced subsidies for agricultural byproducts Ball mills are always preferred to be operated at full capacity because the power consumption of this type of mill is very high at lower loads when compared with other types Ball mills can be designed for a very high capacity like 75 tons per hour output for a specific coal Vertical spindle mill There are many different varieties of vertical Coil Pulverizers for Boilers Bright Hub EngineeringThe types of coal mill equipments – Vertical coal grinding Coal mill include ball mill, raymond mill, vertical mill In coal crushing process, several types of coal crusher are used, such as Types Of Coal Crushers Crusher Mills, Cone Crusher,

Bearing Solutions and Services for Thermal Power Plants

locations in coalfired power plants where bearings are typically used, such as in beater wheel mills, tube and bowl mills, and air preheaters PRODUCTS Everything from one source: From Xlife to service Economical systems in thermal power plants require reliable components SchaefflerThermal Power Station Layout COMPONENTS OF A THERMAL POWER STATION COAL HANDLING PLANT: The function of coal handling plant is automatic feeding of coal to the boiler furnaceThis should be noted that coal thermal power plant burns enormous amounts of coal which may be estimated for 200MW electricity generating plant around 2000 tons per dayThermal Power Plant – Electricity Generation –