Steel Mills: Removing Oil from Scale Pits oilskim

Oil Skimmers, Inc has provided oil removal solutions to many steel mill companies to date One customer, a steel minimill, had employed a vac truck service to periodically vacuum waste oil out of its scale pit But vacuuming takes a lot of water along with the oil, and occasional visits didn't provide a solution to a continuous problem The presence of mill scale is also a hindrance to applying paint or powder coating, which adheres poorly to scale Left in place, the scale will eventually chip and break the coating’s surface, allowing moisture to penetrate It is wasteful to apply a protective coating over a workpiece covered with mill scale For this reason, scale removal Removing Mill Scale from Steel Surfaces Latem Mill scale removal is part of the normal weld preparation to get a quality weld Let us now look at the methods of removal It’s worth understanding that whether using acid cleaning or mechanical cleaning with a grinder of mill scale it is best to Mill Scale Removal Before Welding Mild Steel 3 Ways

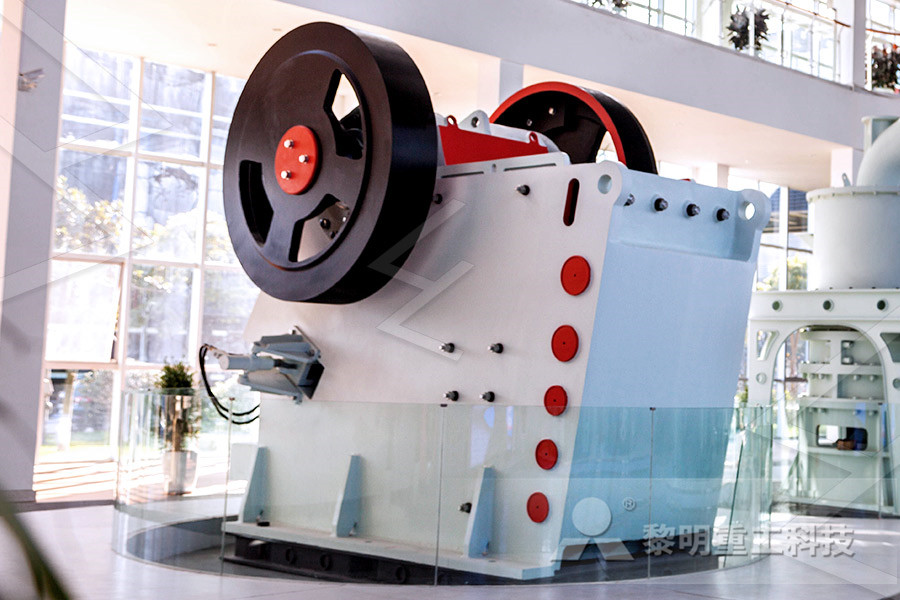

Mill scale removal on steel pipe production line

A basic feature of our mill scale removal machine is the aspiration speed, which must be kept high, in order to remove the mill scale on steel and to avoid its A newly emptied, freshly graded dry slag pit, nominally 120 ft by 45 ft in size, was charged with oily mill scale to a nominal depth of 46 inches, in a restricted area beginning about 1015 feet outward from the point of slag pourout, and continuing outward to cover about 85 percent of the pit areaMethod for removing oil from mill scale and Removing mill scale 05202008, 10:05 AM Hi guys, Maybe you have a slick way of removing mill scale from hot rolled shapes, typically bar stock I have tried wire wheels, 36 grit flap wheels on 41/2" angle grinder and 36 grit Roloc discs on a 2" air Removing mill scale Miller Welding Discussion Forums

Mill Scale

Presidio Fire Pit See Details Whether you need a smoker on skids to put in a pit room, or one that can be taken on the road to cook anywhere, we’ve got you covered2005 A Mill scale consists primarily of magnetite, Fe 3 O 4, of characteristic bluegray "steely" color An extremely thin outer film of hematite, Fe 2 O 3, is invisible to the naked eye The inner portion of the magnetite contains fine metal grains and sometimes, residual black FeO (see below), which contribute to the roughness of descaled metalWhat exactly is Mill Scale and what is done about it It is very smooth with mill scale extremely resistant to removal I have twisted pieces of this red hot and had it not take rust outdoors for over a year I have also hammered it thin while red hot still retaining this scale which challenges wire wheels and sanding disks Dipping it in water red hot won’t even phase it most timesVinegar for scale removal Metallurgy I Forge Iron

Mill Scale Removal

Mill Scale Removal Hi everyone We are trying to remove mill scale from steel prior to a powdercoat What acid is the best to use for the removal of mill scale and rust? I seem to recall that Sulfuric acid is a good one for mill scale, but doesn't do the job on plasma edges Just looking for some confirmation on my memory 1131 Openpit mining Openpit mining is a type of strip mining in which the ore deposit extends very deep in the ground, necessitating the removal of layer upon layer of overburden and ore In many cases, logging of trees and clearcutting or burning of vegetation above the ore deposit may precede removal of the overburden The11 PHASES OF A MINING PROJECT ELAWThe purpose of the benches is to control the depth of the blast holes, the slope of the pit walls, and the dangers of highwall faces The benches also provide enough length of face to allow sustained, uninterrupted production Open pit mining is a large scale method in terms of production rate, responsible for more than 60% of all surface outputAMIT 129: Lesson 2 Open Pit and PPE – Mining Mill Operator

Deoxidizing Aluminum as a Pretreatment Products Finishing

Removal of oxide, mill scale, corrosion products, heattreatment scale or welding fluxes Etching to increase surface area Heavyduty deoxidizing for castings Lightduty deoxidizing In the aerospace industry, for instance, the parts are complex and have tight tolerances for which etching off of material is not acceptable Abanaki Corporation manufactures a wide variety of oil skimmers to meet any size application From a small coolant tank in a lathe to a scale pit in a steel mill, Abanaki Corporation can supply a skimmer to do the job We manufacture skimmers that can remove from 1 gallon per hour to 200 gallons per hourHow to Remove Oil From Water Abanaki Oil Skimmers The Rolling Mill comprises of the following sections: i Primary Descaling ii Roughing stands/ Intermediate stands iii Roller tables iv Finishing Mill v Cooling bed/laminar area vi Down coiler vii Shearing section/finishing yard viii Dispatch yard ix Oil Cellars x Flume tunnels xi Scale pit/settling tank xii Drive mechanismsSAFETY GUIDELINES FOR IRON STEEL SECTOR

Interior View from W within Pipe Mill building, showing

Interior View from W within Pipe Mill building, showing pit exposed by removal of largescale plant scale formation in LTV black liquor evaporators Reducing the content of each of the components that lower the critical solids is the basic approach to controlling this problem Note that each of the three (Na2SO4, Na2CO3 and total Na) is controlled by mill operations outside of the evaporator area The operating approach within theEVAPORATOR FOULING Slide 4 Soluble Sodium (Na) ScalesThe mill scale is carded in the flowing water in the flume to a scale pit where the oil, scale, and water are separated However, the mill scale is now oilwet as a result of contact with the oil in the flume water trench and scale pit In some cases, mill scale may contain up to 10% oilSteel mill flume water treatment Nalco Chemical Company

Pit to crack transition and corrosion fatigue lifetime

Pit to crack transition and corrosion fatigue lifetime reduction estimations by means of a short crack microstructural model where the rate of material removal is typically uniform, slow, pitting can arise where there is a semiprotective film such as mill scale (formed during processing or welding), or due to microbiologically Mill Scale Removal Hi everyone We are trying to remove mill scale from steel prior to a powdercoat What acid is the best to use for the removal of mill scale and rust? I seem to recall that Sulfuric acid is a good one for mill scale, but doesn't do the job on plasma edges Just looking for some confirmation on my memoryMill Scale RemovalThe purpose of the benches is to control the depth of the blast holes, the slope of the pit walls, and the dangers of highwall faces The benches also provide enough length of face to allow sustained, uninterrupted production Open pit mining is a large scale method in terms of production rate, responsible for more than 60% of all surface outputAMIT 129: Lesson 2 Open Pit and PPE – Mining Mill

ScotchBrite XT Pro Extra Cut A new spin on Scotch

Rust, paint, light mill scale removal Maintains workpiece shape, removes coatings Low sparking XTPr o Sharp silicon carbide mineral and reengineered web make a durable disc that won’t damage the base metal ScotchBrite™ Clean and Strip Discs Choose your new XT pit removal without leaving divots Thick paint and coating removal Weld refinement and removing weld discoloration Cuts to bare metal quickly coating removal and Ideal for adhesion prep surface prep Decreased chunking – extended life Highly conformable High speed rating Quickchange, spinon thread XT Pro Rust, paint, light mill scale A new spin ON however, for largescale open pit mining in particular, the \truck and loader" material movement practice is the preferred method of materials handling (Czaplicki, 1992; Ta et al, 2005) Throughout this paper, we consider a \loader" to be any type of high productivity excavating equipment, which may include a mining loader, shovel or excavatorEquipment Selection for Surface Mining: A Review

11 PHASES OF A MINING PROJECT ELAW

1131 Openpit mining Openpit mining is a type of strip mining in which the ore deposit extends very deep in the ground, necessitating the removal of layer upon layer of overburden and ore In many cases, logging of trees and clearcutting or burning of vegetation above the ore deposit may precede removal of the overburden The boating, swimming, camping, commercial and recreational fishing Removal of the source material from the Waste Pits and the river sediment is the only way" to end exposure to toxic chemicals The case is currently pending in state district court and is set for trial in September, 2014 A FLOOD RISK ASSESSMENT OF THE SAN JACINTO RIVER industries The systems are installed at operational, industrial scale plants, where mine drainage or pit water, waste water from tailing storage facilities, and even “produced water” from coal seam methane production are treated The use of treated wastewater varies based on geographic region, treatment method, local dischargeMine Water Treatment Solutions for Discharge and ReUse

Chapter 6 Copper Production Technology Princeton

Removal of most gangue and collection of some byproduct minerals (eg, Mo, Ni, Pb, Zn) to avoid further expense in materials handling, transportation, and smelting Heatinduced separation of complex sulfides into copper sulfides, iron sulfides, and sulfur; removal of sulfur as off gas (SO2) and removal of gangue via slag; in oxygen Mercury contamination from historical gold mines represents a potential risk to human health and the environment This fact sheet provides background information on the use of mercury in historical gold mining and processing operations in California, with emphasis on Mercury Contamination from Historical Gold Mining