Impact Crusher an overview ScienceDirect Topics

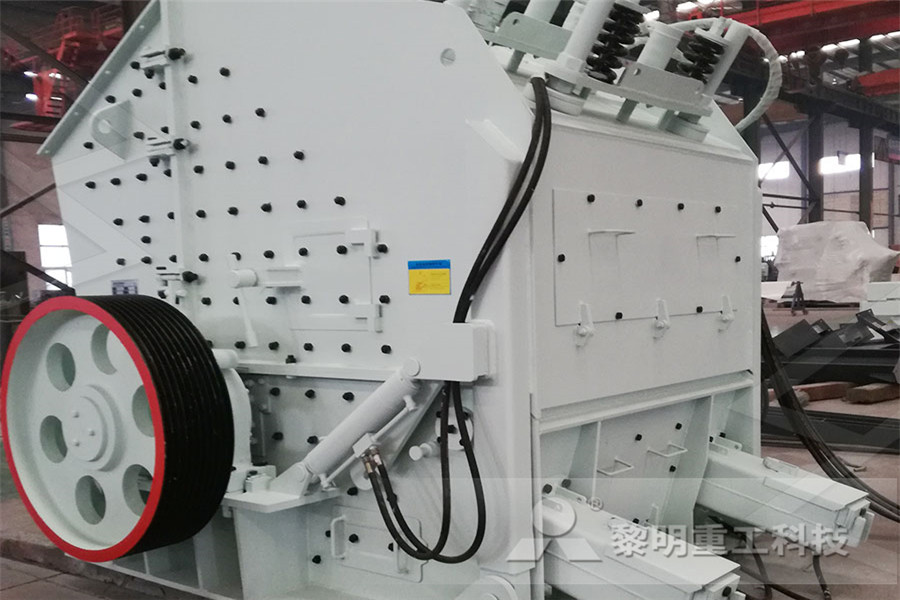

However, due to the crushing board that is easy to wear, it is also limited in the hard material crushing The impact crusher is commonly used for the crushing of limestone, coal, calcium carbide, quartz, dolomite, iron pyrites, gypsum, and chemical raw materials of medium hardness Apron settings can be infinite and its entirely up to you, the operator, as to what size and when you set the apron gaps If you have 2 or 3 impact aprons it makes a difference as does the type of material you are crushing Impact crushers differ from jaws and cones in the fact they impact the rock and don’t compress the rockImpact Crusher Apron Settings MAX PlantImpact Crushers create material reduction by providing a sudden impact force that causes the material to shatter along all the weakest fissures in the stone Controlling the flow of the material through the Impact Crusher requires features that vary from one style of impactor Impact Crushers Primary McLanahan

DESIGN AND ANALYSIS OF A HORIZONTAL SHAFT

The Impact Crusher Machine rotor revolves in fixed direction by means of driving action of triangle belt that connects with motor Above rotor, there are sets of suspended impact plates Material enters into the crushing chamber through the charging hole and feeding guide plate The blow bars fixed on rotor strikes the feed material onto impact plate and then fall from it to mutually shock material blocks Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them Impact crushing can be of two variations: gravity and dynamic An example of gravity impact Impact Crusher Working Principle 911 Metallurgist The vertical shaft impactor uses high rotor speeds (1,000 to 3,000 rpm) to apply high energies to the material, and since Energy + Material = Size Reduction, it can create sand from 2inch feed Requirements for optimum production and wear part utilization include the following: Limit feed size Use metal detection (required)Impact Crushers Stedman Machine Company

Tips to maximize crushing efficiency Pit Quarry :

This is why it is vitally important that the feed arrangement to an impact crusher ensures an even distribution of feed material across the full width of the rotor This will allow for even distribution of energy into the feed material and uniform wear patterns, ensuring consistent product gradation and power consumption Setting impact crushers material has remained unbroken Material crushed in an impact crusher is an example of dynamic impact When the material is crushed in an impact crusher, the freely falling material first breaks due to dynamic impact by a moving hammer and then the force of impact accelerates movement of the reduced particles toward breaker blocks and/or other hammers for further size reductionConstruction, Working and Maintenance of Crushers for Impact crushers use the principle of quick impacts to crush the material and they can be used in any stage of the crushing process However, the features and capabilities of different impact crusher types vary considerably Impact crushers are traditionally classified into two main types, horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers These different types of impact crushers share the crushing principle, impact, to reduce the material Crushing 101 – Different types of crushers for

Crushers an overview ScienceDirect Topics

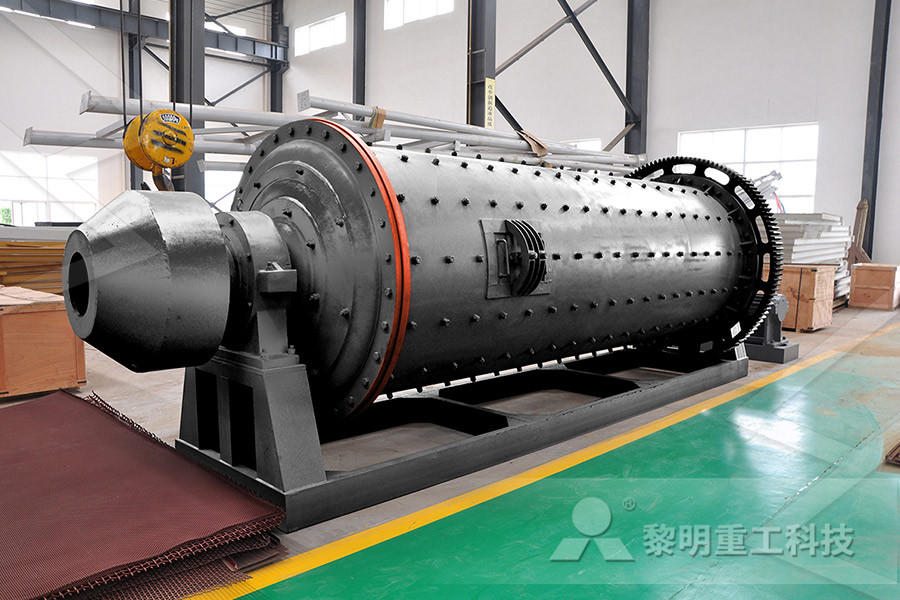

Hammer (impact) crusher: The feed is fragmented by kinetic energy introduced by a rotating mass (the rotor) which projects the material against a fixed surface causing it to shatter causing further particle size reduction This crusher produces more rounded shapeImpact definition: ”The action of one object coming forcibly into contact with another” 60% of the crushing in an impactor will be done on initial impact with the blow bars and the primary apron Then the secondary apron will do 30% and finally the tertiary apron kicks in and does the final 10% Back to the primary settingImpact Crusher Apron Settings MAX PlantMEKA secondary impact crushers are manufactured using two different designs in order to respond to our customers’ different needs One of these designs is the MSI series secondary impact Crusher with two independent breaking plates, which may be adjusted by hydraulic setting rodsSecondary Impact Crushers MEKA Crushing

Construction, Working and Maintenance of Crushers for

material has remained unbroken Material crushed in an impact crusher is an example of dynamic impact When the material is crushed in an impact crusher, the freely falling material first breaks due to dynamic impact by a moving hammer and then the force of impact accelerates movement of the reduced particles toward breaker blocks and/or other Impact crusher capacity charts are developed for use as an application tool to properly utilize the NP crusher’s capabilities The capacity figures shown apply to material weighing 100 pounds per cubic foot or 1600 kg per cubic meter The crusher is one component of the circuit As such, Impact Crushers NP Series Impact Crushers Impact crusher is a widely used crusher machine in ore mining industry Its production efficiency is related to the material nature and structure of the impact crusher, and the discharge opening also has a certain impact on its production efficiency and also has a protective effect on the equipmentHow to adjust the Discharge Opening of the Impact

Crushing 101 – Different types of crushers for

Impact crushers are traditionally classified into two main types, horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers These different types of impact crushers share the crushing principle, impact, to reduce the material to smaller sizes, but features, capacities and optimal applications are far from each other The mobile impact crusher MOBIREX MR 130 Zi EVO2 can be deployed universally as an allrounder and produces first class final product quality With a crusher inlet width of 52“, it achieves a production rate that until now was only associated with considerably larger crushing plantMOBIREX MR 130 Zi EVO2 Wirtgen GroupPercussion crusher: The aggregates are produced by impact and hence higher fines content • Hammer (impact) crusher: The feed is fragmented by kinetic energy introduced by a rotating mass (the rotor) which projects the material against a fixed surface causing it to shatter causing further particle size reduction This crusher produces more Crushers an overview ScienceDirect Topics

Tips for maintaining efficiency in crushing circuits –

Impact crushers An impact crusher uses mass and velocity to break down feed material First, the feed material is reduced as it enters the crusher with the rotating blow bars or hammers in the rotor The secondary breakage occurs as the material is accelerated into the stationary aprons or Aggregates required for a given job are generally specified by a full set of gradation limits and other relevant properties of the material When rock is crushed, the product includes material of the size of the crusher setting, some slightly larger and the rest of the material smaller than the crusher settingCrusher Product Gradation Charts 911 MetallurgistImpact definition: ”The action of one object coming forcibly into contact with another” 60% of the crushing in an impactor will be done on initial impact with the blow bars and the primary apron Then the secondary apron will do 30% and finally the tertiary apron kicks in and does the final 10% Back to the primary settingImpact Crusher Apron Settings MAX Plant

Secondary Impact Crushers MEKA Crushing

MEKA secondary impact crushers are manufactured using two different designs in order to respond to our customers’ different needs One of these designs is the MSI series secondary impact Crusher with two independent breaking plates, which may be adjusted by hydraulic setting rods Impact crusher capacity charts are developed for use as an application tool to properly utilize the NP crusher’s capabilities The capacity figures shown apply to material weighing 100 pounds per cubic foot or 1600 kg per cubic meter The crusher is one component of the circuit As such, Impact Crushers NP Series Impact Crushers The impact chamber features variable rotor speed and hydraulic apron setting assist to provide convenient and efficient adjustment of the chamber aprons It is also fitted with hydraulic overload protection system as standard The machine is built around a robust direct drive ® Ø1034mm x 1000mm (Ø415” x 40”) impact pact Impact Crushers Heavy Duty Finlay

PA6060 Impact Crusher Impact Crushers Telsmith

PA6060 impact crusher is versatile and can be mounted on track or wheeled portable units or onto fixed structures with truck dump hoppers Built heavy with advanced operating features, PA crushers deliver consistent, reliable production with lower operating costs than other brands material has remained unbroken Material crushed in an impact crusher is an example of dynamic impact When the material is crushed in an impact crusher, the freely falling material first breaks due to dynamic impact by a moving hammer and then the force of impact accelerates movement of the reduced particles toward breaker blocks and/or other Construction, Working and Maintenance of Crushers for 512 Impact crushers Breakage is achieved by impact using either hammer the crusher and some material falls through and out A certain amount of fresh feed is also taken in setting of the crusher Data from operating crusher machines indicate that both d1 and d2 are proportional to the closed side settingTECHNICAL NOTES 5 CRUSHERS Mineral Tech

How to adjust the Discharge Opening of the Impact

Impact crusher is a widely used crusher machine in ore mining industry Its production efficiency is related to the material nature and structure of the impact crusher, and the discharge opening also has a certain impact on its production efficiency and also has a protective effect on the equipment Impact crushers are traditionally classified into two main types, horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers These different types of impact crushers share the crushing principle, impact, to reduce the material to smaller sizes, but features, capacities and optimal applications are far from each otherCrushing 101 – Different types of crushers for Impact crushers An impact crusher uses mass and velocity to break down feed material First, the feed material is reduced as it enters the crusher with the rotating blow bars or hammers in the rotor The secondary breakage occurs as the material is accelerated into the stationary aprons or Tips for maintaining efficiency in crushing circuits –