Grinding balls making machine, grinding ball heat

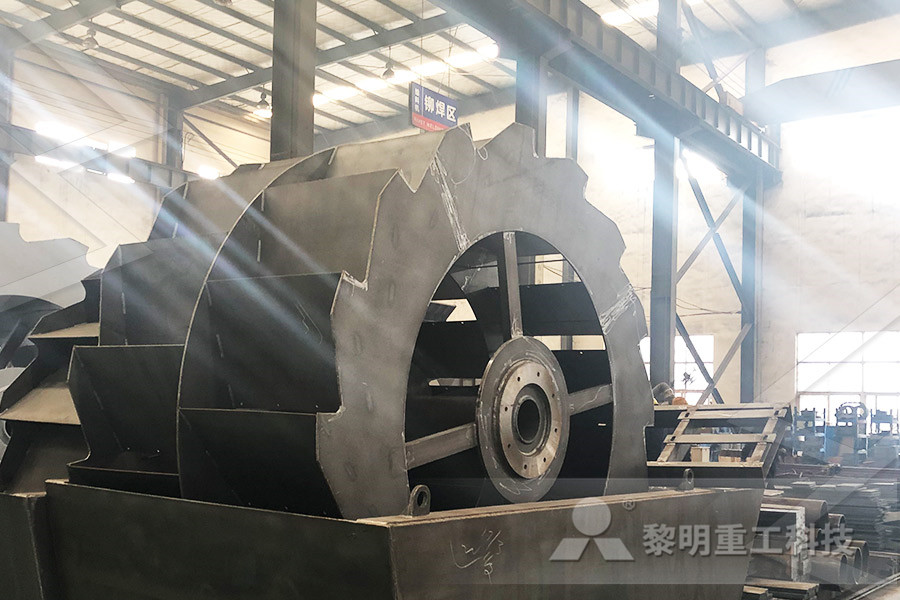

Grinding balls making machine is widely used for grinding balls producing in foundries, including balls making machine: automatic casting grinding media molding line and manual metal mold; heat treatment furnace for grinding balls, contents quenching plant and tempering machine; the balls separator for separating the grinding balls with risers, runners and pouring gates; and then the lab Grinding Rod Allstar Grinding Rod is directly from heated high carbon and chromium alloyed steel bar followed by straightening and inline heat treatment, tailed to give uniform hardness, high resistance to both abrasion and impact, and resistance to Grinding Ball Grinding Steel Ball, Grinding Media Ball 2 天前 Gas Type Heat treatment furnace for grinding balls is used to do heat treatment The furance can do: oil quench,air quench,water quench, tempering etcheat treatment furnace for grinding balls, air quench for

Heat treatment plant,grinding balls producing machine

Automatic screw rolling steel balls production line Tilting type molten iron pouring system automatic casting grinding balls production line Heat treatment machine for grinding media electrical type Gas type heat treatment furnace for grinding balls Medium Frequency Induction Melting Furnace automatic balls separating and sorting machineGrinding ball heat treatment furnace After grinding balls are manufactured in casting ball metal mold or automatic grinding ball molding line, the next most important process is heat treatment Grinding ball heat treatment includes quenching and tempering Grinding ball heat treatment is used to quenching and tempering for casting balls VIEW MOREGrinding Ball Production Equipment, Heat Treatment Furnace Continue Heat Treatment Furnace For Grinding Balls Condition:New Type:resistance furnace Usage:heat treatment furnace Model Number:GKW340C Voltage:380V Power:340kw Dimension(L*W*H):750mm*950mm*10500mm Certification:ISO9001:2008 Capacity:00560ton Max temperature:1200℃ Frequency:50Hz Fuel:electricityGrinding Ball Casting Line, Grinding Ball Heat Treatment

Grinding balls manufacturing process Melting, Molding and

Heat treatment is a vital process for a good ball This process will change the ball’s characteristics, increase the hardness, reduce the inner stress To achieve the formed grinding balls have good impact value and low wear rate This process includes quenching and temperingBalls are hardened by microalloying steel and heat treatment The technology for producing iron balls is more complicated (centrifugal casting); they are used primarily for grinding cement and nonferrous metal ores The wear resistance of such products is increased by alloying cast iron with chromium, vanadium, molybdenum and nickelGrinding balls, buy metal balls from Metinvest manufacturerHigh Carbon Heat Treated (HTR50) MILL LINER BOLT EASY RELEASE BOLT EASY OUT BOLT Molycop manufactures grinding balls to exacting internal specifications at its grinding media production facility across the globe Balls Grind Molycop

Quenching and Partitioning–Based Heat Treatment for Rolled

A “Quenching and Partitioning” (QP)–based heat treatment has been applied to rolled grinding steel (075 wt pct CMnCr) balls of 104mm diameter to prevent their cracking during heat treatmentGrinding Balls Heat Treatment Analysis Feb 10, 2018 Grinding Balls Heat treatment is a kind of technological process that the billet is heated to a certain temperature in a specific environment for a certain period of time and then cooled at different speedsGrinding Balls Heat Treatment Analysis News For grinding balls, the last two ways are the best Moreover, for super high chrome balls, air quenching is welcomed than oil quenching But, like 1018%Cr, oil quenching is the most popular Quenching process: first heating the grinding balls up to the certain degrees in particular time, then quench directly to oil or air for several minutesHeat Treatment Furnace for Grinding Media Balls,Steel

Grinding Ball Casting Line, Grinding Ball Heat

Continue Heat Treatment Furnace For Grinding Balls Condition:New Type:resistance furnace Usage:heat treatment furnace Model Number:GKW340C Voltage:380V Power:340kw Dimension(L*W*H):750mm*950mm*10500mm Certification:ISO9001:2008 Capacity:00560ton Max temperature:1200℃ Frequency:50Hz Fuel:electricity Furnace Heat This work aimed to model the temperature distribution, phase transformation and residual stress induced during the heat treatment of grinding balls of 3 and 5 in diameter The temperature model considered factors such as the heating of the water and the formation of a steam layer that surrounds the balls at the start of the quenchingResidual stress during heat treatment of steel Grinding Ball, ALLSTAR Grindingball, a certified ISO 9001 company, is the worldleading manufacturer of grinding media ball, grinding steel ball, forged steel ball, casting steel ball with annual production capacity of 100,000 metric tonsGrinding Ball Grinding Steel Ball, Grinding Media Ball

heat treatment furnace for grinding balls

heat treatment furnace for grinding balls Function: it is widely used in the quenchingtempering of grinding balls and foundry productsAdopt dual screen PID to adjust temperature controller independently and PLC programming controlTouching screenmalfunction alarmSIZE Molycop manufactures forged grinding balls for use in ball milling and regrind applications in nominal sizes from 10” to 40” in diameter CHEMISTRY An individual chemical profile has been developed for each diameter ball to correspond with the requirements for heat treatment Specific alloy additions are included to produce optimum Grind MolycopIn 1961 the product range was extended by rolled grinding balls The grinding balls are produced by VÍTKOVICE CYLINDERS using worldclass equipment achieving high quality In 1998 the entire production process was reequipped, heat treatment technology (quenching and tempering) was added and the product range was further extendedGrinding balls Vítkovice Cylinders as

Manufacture High Chrome Grinding Media Balls,Steel

The manufacturing process of casting chrome grinding media consists of 6 Main Steps: Melting – Raw material analysis – Molding(making grinding balls) – Separating Cleaning – Heat Treatment – Packaging For each step matches with the certain equipment, including induction melting furnace, balls making production line (metal mold), grinding media separating and cleaning machine, Their main business area is bolts, grinding balls, rods, special hot forgings heat treatment Donhad Pty Ltd have 150 members of staff, and have achieved revenues of AU$80,000,000Donhad Pty Ltd Bolts, grinding balls, rods, special Grinding Ball, ALLSTAR Grindingball, a certified ISO 9001 company, is the worldleading manufacturer of grinding media ball, grinding steel ball, forged steel ball, casting steel ball with annual production capacity of 100,000 metric tonsGrinding Ball Grinding Steel Ball, Grinding Media Ball

Grinding balls, buy metal balls from Metinvest

Such grinding media for ball mills are produced by hotrolling, forging and stamping Balls are hardened by microalloying steel and heat treatment The technology for producing iron balls is more complicated (centrifugal casting); they are used primarily for grinding cement and nonferrous metal oresThe carbon content in steel of the most produced grinding balls, 3 and 5 inch diameter, varies between 06% and 11% and, due to the presence of other addition elements, after their standard heat treatment, all the ball zones –external and central –reach high hardness values: over 60 RC in the case of the 3 inch diameter balls The internal zone, hard and with low tenacity, produces a Improving the Working Life of Steel Grinding Balls by SIZE Molycop manufactures forged grinding balls for use in ball milling and regrind applications in nominal sizes from 10” to 40” in diameter CHEMISTRY An individual chemical profile has been developed for each diameter ball to correspond with the requirements for heat treatment Specific alloy additions are included to produce optimum Grind Molycop

heat treatment furnace for grinding balls

heat treatment furnace for grinding balls Function: it is widely used in the quenchingtempering of grinding balls and foundry productsAdopt dual screen PID to adjust temperature controller independently and PLC programming controlTouching screenmalfunction alarmGrinding ball manual mold There are two ways to produce cast grinding ballsOne is automatic grinding ball molding line by machine;the other is grinding ball mold by handIn this part,mainly introduce grinding bal mould by handOne pair grinding ball dies includes top mold and bottom moldWhen production,it also need patternUsually,Dia 50mm mold,40 pairs mold needs 1 pcs 50mm patterGrinding Ball Production Equipment, Heat Treatment The manufacturing process of casting chrome grinding media consists of 6 Main Steps: Melting – Raw material analysis – Molding(making grinding balls) – Separating Cleaning – Heat Treatment – Packaging For each step matches with the certain equipment, including induction melting furnace, balls making production line (metal mold), grinding media separating and cleaning machine, Manufacture High Chrome Grinding Media Balls,Steel

Grinding Media Balls, Grinding Balls, ग्राइंडिंग

This grinding media for ball mills, pulverizers and attritors is cold forged and ground The hardened steel balls (shots, beads) are available in different hardness, as required, in both high carbon steel and chrome alloy steel Precise heat treatment insures their resistance to flaking, chipping or spellingCr ≥12% Cast Chrome Grinding BallsChrome Cast Steel Grinding balls are especially used in the mining industry, and chosen according to customers' requirements and grinding applications It has very high chromium content ranging from lower 10% up to 32% The balls Cr ≥12% Cast Chrome Grinding Balls – KemcoreThe grinding balls work under severe wear conditions Different stresses taking place during the grinding operation may cause material wear whose rate differs from material type or manufacturing process As a result, these numerous stresses can alter the life cycle of the material In the grinding field, there are grinding bodies made of chromium cast iron and forged steelEffect of heat treatment on tribological behavior of