gypsum production process plant design

design of gypsum production plant A GYPSUM PLASTERBOARD PLANT A gypsum plasterboard is a construction material that is is produced in a continuous production process by pouring gypsum Gypsemna Gypsum boards Dubai Abu Dhabi UAE Gypsemna Gypsum boards was established in 2006 by setting up the first world scale gypsum plasterboard plant in UAE's with an annual production capacity Plant Design CaSO42H2O (Gypsum) From CaCO3 and H2SO4 8 With Capacity 100000 Ton/Year Lateefee yangok D Universitas Muhammadiyah Surakarta 14 The Process Selection 141 Kind of Process 1 Preparation of Gypsum from Rock The process of making gypsum from rock is by destroying the rocks gypsum obtained from mountain areasPlant Design CaSO42H2O (Gypsum) From CaCO3 and Plant and Pilot Scale Process Testing and Design With challenging characteristics and wide variability, testing is often a critical component in the success of a gypsum processing operation The FEECO Innovation Center is a unique testing facility where we can test your material at both batch and pilot scale in order to work out process Gypsum Processing FEECO

1116 Gypsum Manufacturing US EPA

1116 Gypsum Manufacturing 11161 Process Description12 Gypsum is calcium sulfate dihydrate (CaSO4 2H2O), a white or gray naturally occurring mineral Raw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, and gypsum wallboard To produce plasters or PRELIMINARY PLANT DESIGN OF GYPSUM USING LIMESTONE AND SULFURIC ACID WITH CAPACITY OF 100,000 TONS/YEAR Abstract Gypsum or calcium sulfate dihydrate requirement in Indonesia is fulfilled with domestic production and imported from abroad Domestic gypsum production is still not sufficient to meet the needs of gypsum in IndonesiaPRELIMINARY PLANT DESIGN OF GYPSUM USING Our Services for your gypsum production plant Partnership Design, construction and commissioning of a new gypsum production line are only the first steps in a good customer relationship Professional service in daytoday operation is just as important: we want your investment to be consistently profitable – that's why our engineers are Gypsum: production solutions Grenzebach

Production of commercialgrade gypsum Power

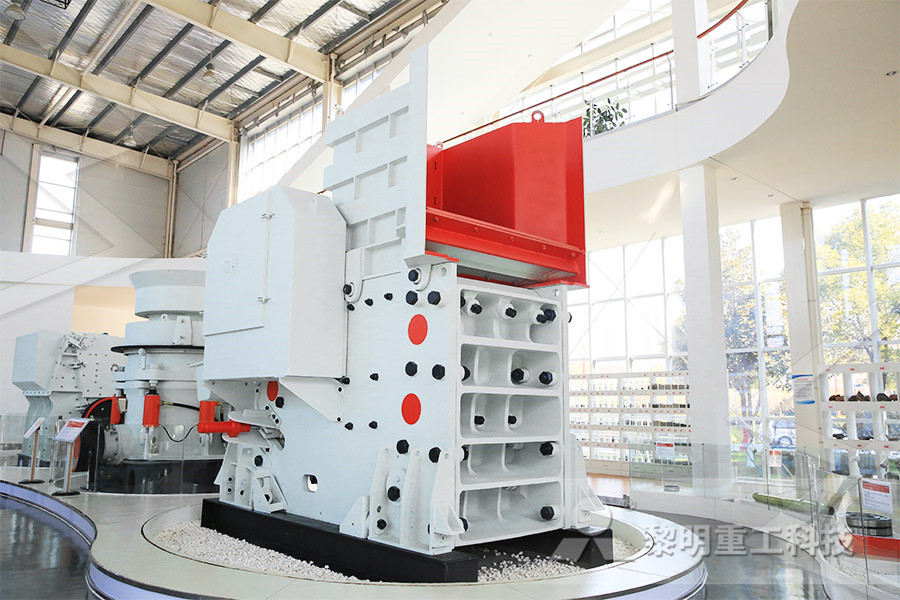

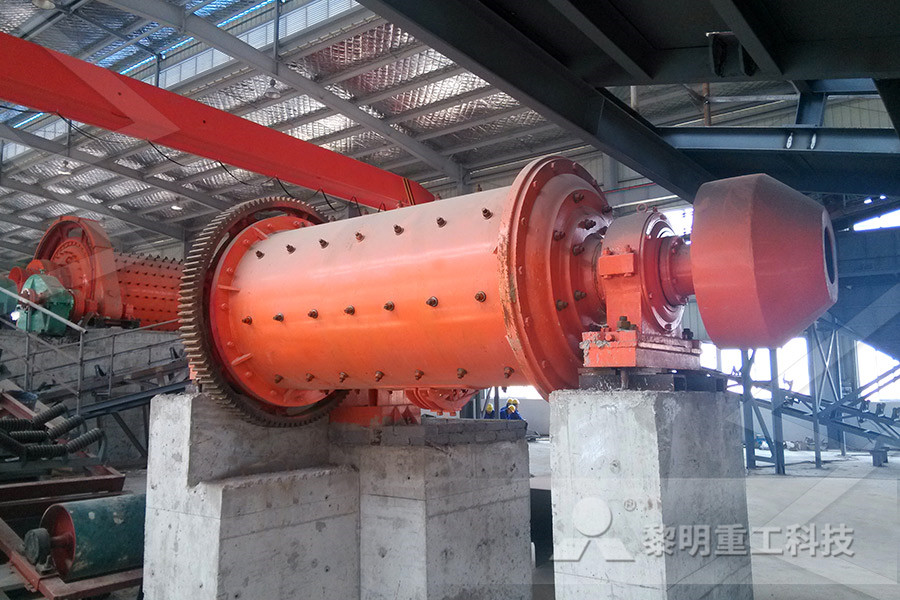

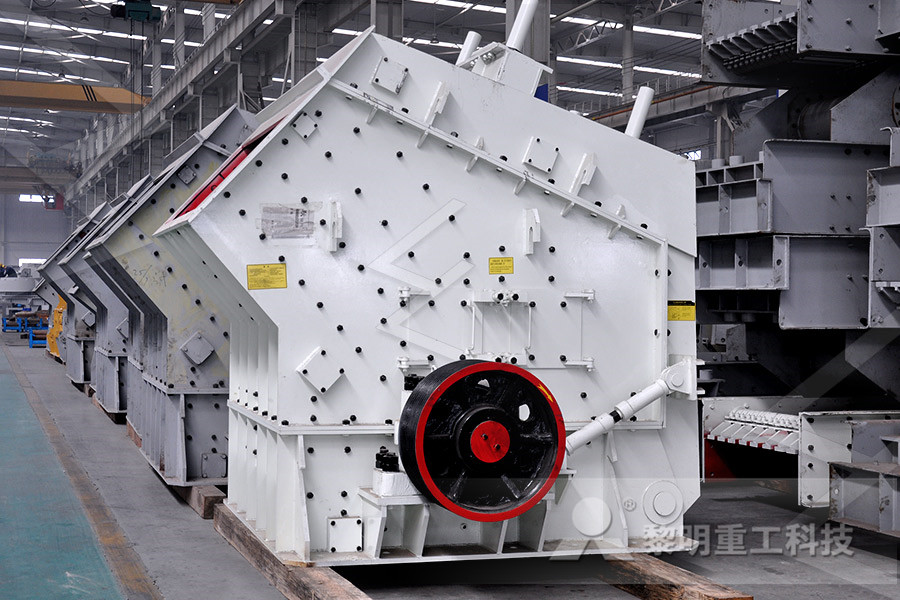

Gypsum from a plant's FGD system can be a lucrative way for coalfired plants to avoid landfill disposal requirements and recover some plant operation costs However, utilities must consider some Gypsum processing equipment differs significantly in scale and level of technology some plants produce one or two tonnes per day using lowcost manual technologies, some other plants of a thousand tonnes per day that are highly mechanized and capable of producing different types and grades of gypsum plaster or plaster boardsGypsum Mining Processing Equipment Flow Chart Gypsumboard face paper is commonly 100 percent recycled from newsprint, cardboard, and other postconsumer waste streams, but most recycled gypsum in wallboard products is postindustrial, made from gypsumboard manufacture Gypsum board should be purchased in sizes that minimize the need for trimming (saving time and waste)Synthetic Gypsum an overview ScienceDirect Topics

BASF Solutions for Gypsum Wallboards Applications

Gypsum wallboards are part of the prefabricated products The production of gypsum wallboards is a very long period optimized process and so complex that even a small change in chemical additives used in the system or adjustment of any production parameter can destabilize the whole optimized process and can create troubles Plant Design CaSO42H2O (Gypsum) From CaCO3 and H2SO4 8 With Capacity 100000 Ton/Year Lateefee yangok D Universitas Muhammadiyah Surakarta 14 The Process Selection 141 Kind of Process 1 Preparation of Gypsum from Rock The process of making gypsum from rock is by destroying the rocks gypsum obtained from mountain areasPlant Design CaSO42H2O (Gypsum) From CaCO3 and Our Services for your gypsum production plant Partnership Design, construction and commissioning of a new gypsum production line are only the first steps in a good customer relationship Professional service in daytoday operation is just as important: we want your investment to be consistently profitable – that's why our engineers are Gypsum: production solutions Grenzebach

Gypsum Processing FEECO

Plant and Pilot Scale Process Testing and Design With challenging characteristics and wide variability, testing is often a critical component in the success of a gypsum processing operation The FEECO Innovation Center is a unique testing facility where we can test your material at both batch and pilot scale in order to work out process The production of wet process phosphoric acid generates a considerable quantity of acidic U S generally use a dihydrate process that produces gypsum in the form of calcium sulfate with 2 molecules of water Final disposition of the volatilized fluorine depends on the design and operation of the plantAP42, CH 89: Phosphoric Acid Desulfurization Gypsum Treatment ProcessProcess Selection On the basis of different capacities and user, we prepare two kinds of production process for our customers The first is onestep production process which is based on boiling kiln This process make use of our mature boiling kiln as the calcining facility and apply theDesulfurization Gypsum Production Line

1116 Gypsum Manufacturing US EPA

1116 Gypsum Manufacturing 11161 Process Description12 Gypsum is calcium sulfate dihydrate (CaSO4 2H2O), a white or gray naturally occurring mineral Raw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, and gypsum wallboard To produce plasters or Gypsum wallboards are part of the prefabricated products The production of gypsum wallboards is a very long period optimized process and so complex that even a small change in chemical additives used in the system or adjustment of any production parameter can destabilize the whole optimized process and can create troublesBASF Solutions for Gypsum Wallboards ApplicationsUsing a process referred to as ‘scrubbing,’ gas pollutants are fed through calcium carbonate to eliminate impurities and environmental concerns When the sulfur dioxide is removed, the gypsum byproduct is formed 4 Common Uses for Synthetic Gypsum Synthetic gypsum is used interchangeably with natural gypsum in a number of applications6 Facts about Synthetic Gypsum FEECO

Analysis and Simulation of Dihydrate Process for the

(gypsum) by adding a mixed solution of sulfuric and phosphoric acids to the reactor The main process used in industrial practice for phosphoric acid production is the “wet method”, which includes singlestage and recrystallization processes The singlestage processes consist of a single reactioncrystallization step and the most The dryer is one of the most critical steps in the wallboard production process and so it makes sense to use the company’s extensive expertise in this field In actual fact, Münstermann’s first move into the gypsum sector was the launch of a dryer for gypsum blocks, manufactured for a Rigips factory in SwitzerlandMünstermann: A decade in gypsum dryers Plant Design CaSO42H2O (Gypsum) From CaCO3 and H2SO4 8 With Capacity 100000 Ton/Year Lateefee yangok D Universitas Muhammadiyah Surakarta 14 The Process Selection 141 Kind of Process 1 Preparation of Gypsum from Rock The process of making gypsum from rock is by destroying the rocks gypsum obtained from mountain areasPlant Design CaSO42H2O (Gypsum) From CaCO3 and

GYSPSUM PRODUCTION PLANT – Deha Tech

Gypsum production plants will be designed specifically according to demanded capacities to be required in production and also final product specifications to be obtained Gypsum Production Process has become an important study in terms of the product development and improvement of gypsum plant Gypsum has many types with usages in 1116 Gypsum Manufacturing 11161 Process Description12 Gypsum is calcium sulfate dihydrate (CaSO4 2H2O), a white or gray naturally occurring mineral Raw gypsum ore is processed into a variety of products such as a portland cement additive, soil conditioner, industrial and building plasters, and gypsum wallboard To produce plasters or1116 Gypsum Manufacturing US EPA Knauf uses the gypsum that emerges from the end of this process and, in 2019, the Company took back around 45,000 tonnes of recycled gypsum from Countrystyle for use in its manufacturing Matt Wood, Manufacturing Manager at Knauf Sittingbourne, said “Around 10% of the gypsum in our finished board products is from recycled gypsumImproving and using recycled gypsum Knauf

6 Facts about Synthetic Gypsum FEECO

Using a process referred to as ‘scrubbing,’ gas pollutants are fed through calcium carbonate to eliminate impurities and environmental concerns When the sulfur dioxide is removed, the gypsum byproduct is formed 4 Common Uses for Synthetic Gypsum Synthetic gypsum is used interchangeably with natural gypsum in a number of applications Global Gypsum Knowledge Base The Global Gypsum Knowledge Base is an archive of Global Gypsum Magazine, the Global Gypsum Directory and papers from the Global Gypsum Conference since 2007 Global Gypsum is wellknown as the foremost source of information for the global gypsum Global Gypsum Knowledge Base, news, plants more (gypsum) by adding a mixed solution of sulfuric and phosphoric acids to the reactor The main process used in industrial practice for phosphoric acid production is the “wet method”, which includes singlestage and recrystallization processes The singlestage processes consist of a single reactioncrystallization step and the mostAnalysis and Simulation of Dihydrate Process for the

Münstermann: A decade in gypsum dryers

The dryer is one of the most critical steps in the wallboard production process and so it makes sense to use the company’s extensive expertise in this field In actual fact, Münstermann’s first move into the gypsum sector was the launch of a dryer for gypsum blocks, manufactured for a Rigips factory in Switzerland🕑 Reading time: 1 minuteGypsum is a mineral and is hydrated calcium sulphate in chemical form Gypsum plays a very important role in controlling the rate of hardening of the cement, so its is generally termed as retarding agent of cement It is mainly used for regulating the setting time of cement and is an indispensable []Role of Gypsum in Cement and its Effects The UIF Polycondensation Technologies provides a full range of plant design options: 1 Plants for the exclusive production of LA, lactide or PLA 2 Plants for the combined production of either LA and lactide or lactide and PLA 3 Fully integrated plants for the production of the complete process Polylactide Technology ThyssenKrupp