Double Toggle Jaw Crusher Manufacturer/exporter in

The lower output explanation is somewhat deceptive on the grounds that it's halfway credited to the kind of course they have versus present day crusher, so if one somehow happened to overhaul the direction, throughput could be nearer to that of a new generation jaw As well as our double toggled jaw crusher need a small size DT Series Double Toggle Primary Jaw Crusher DT Series Double Toggle Jaw Crushers are Heavy Duty Equipment designed to operate in the toughest of conditions These machines are able to crush the hardest of stones They operate on the principle of crushing without rubbing Hence the jaw plate consumption is very lowDT Series Double Toggle Primary Jaw Crusher 3624 28 行 Double Toggle Oil Jaw Crusher The output is based on average hard dry quarts of Manufacturer of Double Toggle Oil Jaw Crusher in India

Jaw Stone Crusher Single Toggle vs Double Toggle

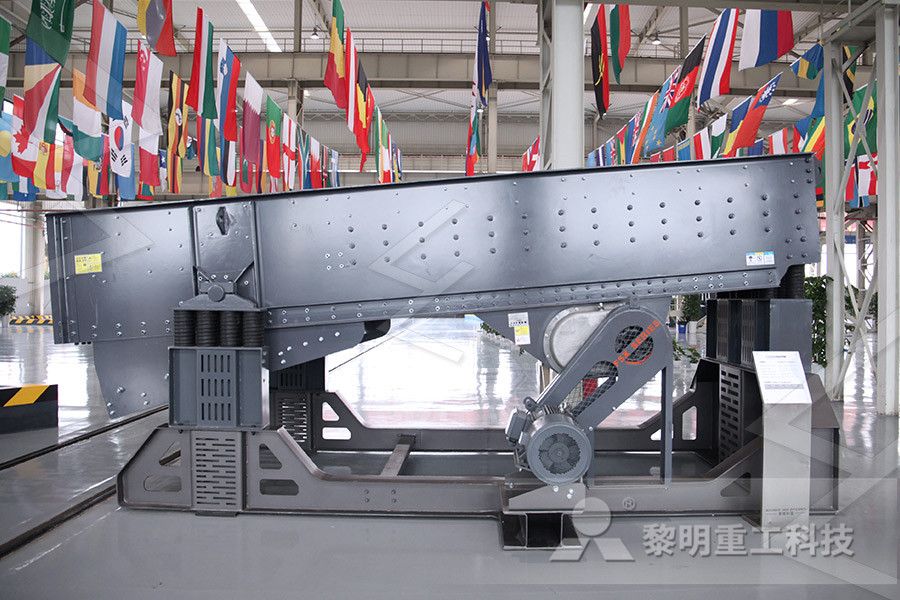

Compared with the single toggle jaw stone crusher, the doubletoggle jaw crusher has the following advantages: less weight, fewer components, more compact structure, a better filling degree in the crushing chamber, even crushing of the loaded material block, and forced unloading of the finished product by moving the lower jawManufacturer of Jaw Crushers Stone Jaw Crusher, Jaw Crusher, Single Toggle Jaw Crusher and Double Toggle Jaw Crusher offered by Pronex, Chennai, Tamil NaduJaw Crushers Stone Jaw Crusher Manufacturer from A jaw crusher has a wider range of settings—generally, a maximum of two to three times the smallest setting The tables also show that for a comparable maximum size of feed and setting, a gyratory crusher has a much greater capacity than a jaw crusherEstimate Jaw Crusher Capacity 911 Metallurgist

Double Toggle Jaw Crusher at Best Price in India

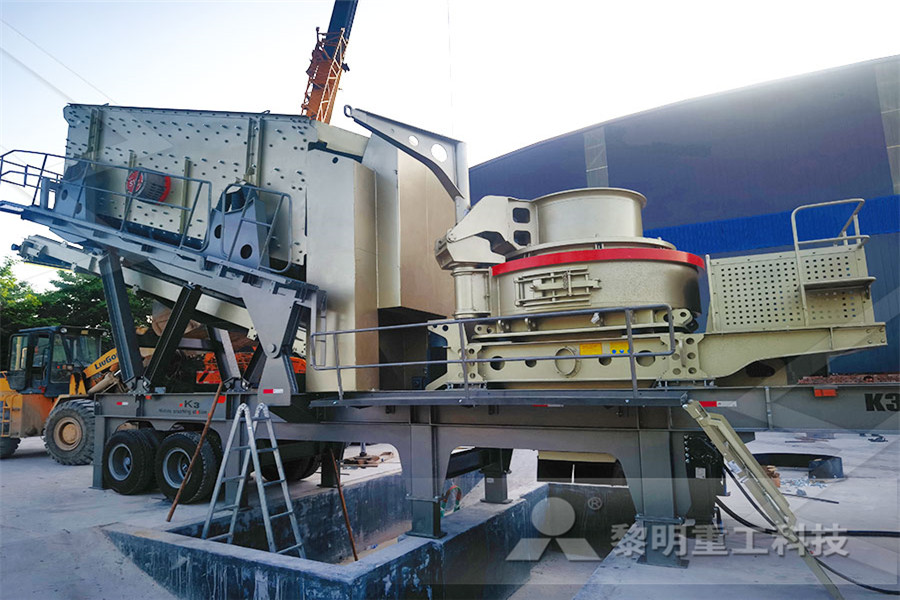

Double Toggle Jaw Crusher, which has been widely used in mining, metallurgy, highway, railway and water conservancy, is one of the most popular equipments in the mining production Jaw Crusher is one perfect Iron Ore Crusher Machine widely used in many Jaw crusher is a compression style rock crusher, useful in crushing the mediumhard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit Applications mining, quarry, construction waste recycling, aggregate making, etc Materials Limestone, cobblestone, cobblestone, quartz, basalt, iron ore, granite, shale, sandstone, gypsum, and a variety of oresJaw Crusher Eastman Rock Crusher The size of a jaw crusher is usually described by the gape and the width, expressed as gape × width The common crusher types, sizes and their performance are summarised in Table 41Currently, the dimensions of the largest Blaketype jaw crusher in use are 1600 mm × Jaw Crusher ScienceDirect

Primary Crusher Selection Design 911 Metallurgist

How you select your primary crusher will be based on factors like moisture content, maximum rock lump size, material density SG, abrasion index, degradability and it being prone to dusting or not The crusher capacities given by manufacturers are Jaw Crusher Double Toggle Oil Type Jaw Crusher, Double Supplier and Manufacturer of Jaw Crusher, Minimum Output Size mm : 150 4 Maximum Input Capacity TPH : 100 to 125 5 Ideal Usage : output size of jaw crusher chinaInput size coutput size and capacity of double Crusher plant mineral aggregate processing jxsc mine raw material granite required capacity 250th max feedinput size mm output size 095mm95125mm12519mm1925mm input size coutput size and capacity of double toggle jaw DetailsJaw Crusher Feed Size Mm Specification Honduras

Jaw Crusher Nesans Mining and Automation Private

Nesans premium range jaw crushers are higher capacity stone or mineral processing crusher used in the primary stage and secondary stage of crushing That is to designed for the capacity range from 50 to 400 TPH, our jaw crushers shall be put into use for stones and minerals with varying crushing and abrasive indexGenerally jaw and impact crushers exhibit a large reduction factor defined as the ratio of the particle size of the input to that of the output material A jaw crusher crushes only a small proportion of the original aggregate particles but an impact crusher crushes mortar and aggregate particles alike and thus generates a higher amount ofInput To Output Ratio Of Stone Jaw Crusherjaw crusher basic shape and dimensions,Design And Analysis Of A Horizontal Shaft Chapter 3 Design of Basic Components Design of hammerblow bar 14 input of these crushers is relatively wider and the output products are coarser in size Example Jaw crusher Gyratory crusher Impact Crushers etc the shape and size of the outputjaw crusher basic shape and dimensions Simone

Jaw Crusher Output Size yogaingreifswaldde

Jaw Crusher With Material Output Size Mmsmall Mobile Jaw crusher output size mm jaw crusher output size mm leave a reply 03july specification of 10 tph jaw crusher for gravel jaw crusher is widely used for crushing stone rock gravel granite dolomite etc and jaw crusher has a series of different models but if you are looking for a 10 tph jaw crusher the search scope is shrunk greatly7jaw crusher spare parts: 8Jaw crusher from stock : 9Q: For providing you the suitable quotation we need to know the following information: A: 1What is the raw material for the production line? 2 What is the capacity per hour you required? 3 What is the maximum input size of the raw material? 4 What is the output size and application for China Latest Design Jaw Crusher Stone Crusher As a classic primary crusher with stable performances, Jaw Crusher is widely used to crush metallic and nonmetallic ores as well as building aggregates or to make artificial sand Input Size: 01020mm Capacity: 45800TPH Materials: Granite, marble, basalt, crusher crusher output sizes visueelvertalerbe

Jaw Crusher an overview ScienceDirect Topics

The ore is to be broken down in a jaw crusher to pass through a 115 cm screen The undersize is scalped before feeding to the jaw crusher Assuming the maximum feed rate is maintained at 30 t/h and the shapes of feed and product are the same and the crusher set is 10 cm, estimate the size of jaw crusher required and the production rate Solution2Crushing Capacity as compare to double toggle is 10 to 20 % more, but life of jaw plates is less as compare to double toggle jaw crusher The size of required output material can be taken in closed side settings as compare to double toggle jaw crusher 3The power consumption in single toggle is less than double toggle jaw crusherCrusher Machine and Plant Single Toggle Jaw Input size coutput size and capacity of double Crusher plant mineral aggregate processing jxsc mine raw material granite required capacity 250th max feedinput size mm output size 095mm95125mm12519mm1925mm input size coutput size and capacity of double toggle jaw DetailsJaw Crusher Feed Size Mm Specification Honduras

Input To Output Ratio Of Stone Jaw Crusher

Generally jaw and impact crushers exhibit a large reduction factor defined as the ratio of the particle size of the input to that of the output material A jaw crusher crushes only a small proportion of the original aggregate particles but an impact crusher crushes mortar and aggregate particles alike and thus generates a higher amount ofJaw Crushers Osborn Note: Crusher output gradations and tons per hour products may change due to Single Toggle Jaw Crusher Double Toggle Jaw Crusher Inquire Now; how to calculate output of voltas crusher plant how to calculate output of voltas crusher plant is manufactured from Shanghai ,It is the main jaw crusher, impact crusher output formula jaw crusher jackysbnbcozaJaw Crusher is a basic sample preparation unit to address all primary size reduction requirements 150 mm input size Upto 3 mm size, is achieved by faster and efficient crushing with 2 stage process Movable Jaw with toggle speed of numerous strokes per minuteHardened steel Blades Minimum sample contamination Estimate Jaw Crusher Capacityjaw crusher output size 5mm wstarympalacupl

crusher crusher output sizes visueelvertalerbe

As a classic primary crusher with stable performances, Jaw Crusher is widely used to crush metallic and nonmetallic ores as well as building aggregates or to make artificial sand Input Size: 01020mm Capacity: 45800TPH Materials: Granite, marble, basalt, Capacity And Sizes Of Different Jaw Crushers Capacity and sizes of different jaw crushers jaw crusher str type kleemann offers a range of jaw crushers for different feed and grain sizes and performance capacity the single toggle jaw crusher of the str type has openings up to 1600 x 2100 mm in sizeCapacity Of Jaw Crusher In Different Css Jaw CrusherIt has one stationary jaw (like the upper teeth set) and the other movable (like the lower teeth set) with the material to be crushed (food to be chewed) fed inside the two jaws (mouth) and crushed (chewed) to the desired size and discharged (swallowed) to accommodate fresh input of material (food) Jaw Crushers based on Single Toggle (Grease Jaw Crushers Roll Crusher Manufacturer from Gurgaon

jaw crusher discharge size netwerkoostkampbe

Jaw Crusher 1/1/2016The size of a jaw crusher is usually described by the gape and the width, expressed as gape width The common crusher types, sizes and their performance are summarised in Table 41 Currently, the dimensions of the largest Blaketype jaw crusher in use are 1600 mm 2514 mm with motor ratings of 250–300 kW Get priceSome of the crushing ratios can reach 135, and the work is smooth, vibration is small Jaw crusher is intermittent crushing, crushing efficiency is relatively low The feeding way is different, any side of the gyratory crusher can feed, and can be crowded to feed, high efficiency Jaw crusher cant be full feed Input/output particle sizejaw crusher and crusher difference Cornish Rolls These had limitations on feed input size 2/25/2015 6:58:05 AM 4 5 Jaw Crushers The next development in the field was the invention of Jaw Crushers in 1840’s in North America Eli Blake patented the Double toggle Blake Jaw Crusher in 1858Crushing of coal and calculation of size reduction