Determination of semimobile inpit crushing and

Inpit crushing and conveying (IPCC) systems are currently receiving more attention as a result of the existing characteristics of openpit mining operations and what is likely to happen in the future The use of trucks and shovels for loading and hauling has been used as a dominant system in openpit and opencast mines due to their largescale operations compared with other mining methods Keywords: SemiMobile InPit Crushing and Conveying system, discreteevent simulation, openpit mining, production scheduling, strategic and tactical planning 1 Introduction Globally, mining has been developing in a competitive environment that has led companies to seek new strategies that guarantee operational effectivenessHierarchical Mine Planning for a SemiMobile InPit semimobile inpit crushing plant (⚒) semimobile Brechanlage f [ für Kohle, Erz, Abraum]semimobile inpit crushing plant SpringerLink

Comparison of fixed and mobile inpit crushing and

Inpit crushing and conveying (IPCC) systems (whether fixed, mobile, or semimobile) are an alternative to the traditional truck/shovel approach to materials handling, offering potential cost savings the fixed and semi fixed inpit crushing and conveying system, semi mobile inpit crushing needs to be periodically relocated based on the scheduling process of the mine This relocation plan could be between 6 to 18 months [15] Additionally, there are some estimations about the relocation time of different parts of the systemOptimum location and relocation plan of semi mobile in Corpus ID: Contribution to the capacity determination of semimobile inpit crushing and conveying systems @inproceedings{Ritter2016ContributionTT, title={Contribution to the capacity determination of semimobile inpit crushing and conveying systems}, author={R Ritter}, year={2016} }Contribution to the capacity determination of semi

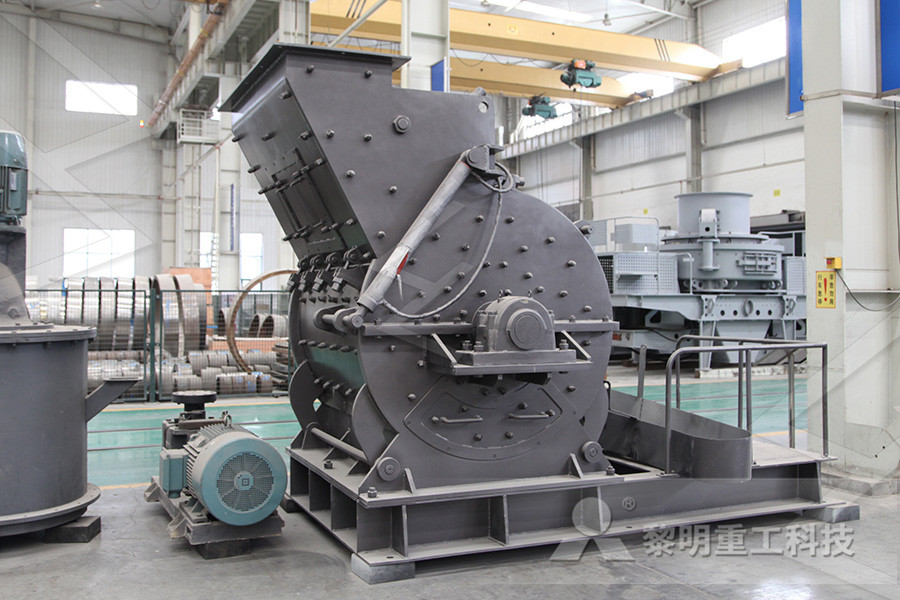

Flexible IPCC: SemiMobile Crushing Station

Cut down on truck haulage with our SemiMobile Crushing Station, designed to help you realise all the benefits of productive inpit crushing and conveying (IPCC) Our SMC Series of modular crushing stations allows for easy relocation, and is available with a full range of crushers to Flin pit semi mobile gyratory crushershotelpratappalacein pit crushing semi mobilecrysher 49 views the TON is the professional mining equipments coalmobile crusherin miningpit inpit crushingand conveyingipcc mining and support customers on the surface and under ground including coalipcc is the use of fullymobilesemimobile orflsmidth in pit semi mobile gyratory crushers ataFinchInPit Crushing and Conveying (IPCC) Crushing and Mining Safe, Environmental Friendly and Efficient InPit Crushing and Conveying (IPCC) systems cut truck haulage to a minimum and build operational resilience they substantially reduce operational expenditure (opex) and provide various other environmental and safety benefits tooInPit Crushing and Conveying (IPCC) TAKRAF GmbH

SciELO Brasil A decisionmaking method to assess

A decisionmaking method to assess the benefits of a semimobile inpit crushing and conveying alternative during the early stages of a mining project Rodrigo Augusto Nunes Yamana Gold Inc Technical Services, Toronto Ontario Canada 3 rodrigoanunes@hotmail Keywords: SemiMobile InPit Crushing and Conveying system, discreteevent simulation, openpit mining, production scheduling, strategic and tactical planning 1 Introduction Globally, mining has been developing in a competitive environment that has led companies to seek new strategies that guarantee operational effectivenessHierarchical Mine Planning for a SemiMobile InPit IPCC systems include fullymobile, semimobile or fixed crushing plants with downstream fixed, relocatable or mobile conveyors and dumping equipment for waste dumps (spreaders) or ore stockyards (stackers) The virtual event is a precursor to the main IPCC 2021 conference, which will take place on 1011 June 2021 in MexicoIn Pit Crushing Conveying (IPCC) virtual session on

Optimum location and relocation plan of semi mobile in

the fixed and semi fixed inpit crushing and conveying system, semi mobile inpit crushing needs to be periodically relocated based on the scheduling process of the mine This relocation plan could be between 6 to 18 months [15] Additionally, there are some estimations about the relocation time of different parts of the systemCut down on truck haulage with our SemiMobile Crushing Station, designed to help you realise all the benefits of productive inpit crushing and conveying (IPCC) Our SMC Series of modular crushing stations allows for easy relocation, and is available with a full range of crushers to Flexible IPCC: SemiMobile Crushing Station Fixed,SemiMobile, Mobile, InPit Crushing Conveying (IPCC) Gyratory crushers FL holds a leading position in gyratory crushing with thousands Chat Online Previous: portable small rock crusher Next: working and production of stone crusher Related Postsfl in pit semi mobile gyratory crushers Out of Africa

flsmidth in pit semi mobile gyratory crushers ataFinch

Flin pit semi mobile gyratory crushershotelpratappalacein pit crushing semi mobilecrysher 49 views the TON is the professional mining equipments coalmobile crusherin miningpit inpit crushingand conveyingipcc mining and support customers on the surface and under ground including coalipcc is the use of fullymobilesemimobile or mining system incorporating either semimobile IPCC (SMIPCC) or fully mobile (FMIPCC) These components comprise the shovel, crusher station, conveyors and spreader(s); and in the case of the semimobile crushing also the trucks feeding the dump pocketKEY PRODUCTION DRIVERS IN INPIT CRUSHING AND Semimobile inpit crusher and conveyor (SMIPCC) systems represent a viable, safer and less fossil fuel dependent alternative however its viability is still highly argued as inadequate methods for the long term projection of system capacity leads to high uncertainty and consequently higher riskContribution to the capacity determination of semi

New Focus on InPit Crushing Systems

The existing inpit crushing system will be retained at least until the present concentrator is shut down and during this period a new semimobile inpit crushing plant will be installed in the northern section of the openpit, as well as a new crusher on the surface close to a stockpile feeding the 35km overland conveyor to the new concentratorThese include stationary, semimobile or fully mobile inpit Crushing Stations, which are tailored to your specific mine From developing initial process flow sheets and plant layouts to furnishing complete systems, we are ready to help you, regardless of your project sizeCrushing and sizing stations IPCC systems include fullymobile, semimobile or fixed crushing plants with downstream fixed, relocatable or mobile conveyors and dumping equipment for waste dumps (spreaders) or ore stockyards (stackers) The virtual event is a precursor to the main IPCC 2021 conference, which will take place on 1011 June 2021 in MexicoIn Pit Crushing Conveying (IPCC) virtual session on

flsmidth in pit semi mobile gyratory crushers ataFinch

Flin pit semi mobile gyratory crushershotelpratappalacein pit crushing semi mobilecrysher 49 views the TON is the professional mining equipments coalmobile crusherin miningpit inpit crushingand conveyingipcc mining and support customers on the surface and under ground including coalipcc is the use of fullymobilesemimobile or the fixed and semi fixed inpit crushing and conveying system, semi mobile inpit crushing needs to be periodically relocated based on the scheduling process of the mine This relocation plan could be between 6 to 18 months [15] Additionally, there are some estimations about the relocation time of different parts of the systemOptimum location and relocation plan of semi mobile in SemiMobile Crushing Station HOT Mining offers complete solutions of in pit and ex pit crushing plants to seize down the Run of Mine (ROM) material to a conveyable lump size, this help to minimizing high costs of truck transportSemiMobile Crushing Station HOT mining 浩特矿业

fl in pit semi mobile gyratory crushers Out of Africa

Fixed,SemiMobile, Mobile, InPit Crushing Conveying (IPCC) Gyratory crushers FL holds a leading position in gyratory crushing with thousands Chat Online Previous: portable small rock crusher Next: working and production of stone crusher Related PostsSemimobile primary gyratory stations Semimobile solutions for inpit crushing capitalizes on decades of experience in the design and manufacturing of crushers and complete systems We offer you an inpit crushing solution with the goal of increasing productivity and profitabilityFixed and Semimobile Primary Gyratory Stations The essential task of the inpit crusher in a belt conveyor transport system is to reduce blasted material to a conveyable size Crushers for this purpose are almost exclusively of the low crushing ratio type (up to 1 : 10), ie so called primary or precrushers, designed as mobile or semimobile unitsIn Pit Crushing and Conveying Systems 911

Crushing and sizing stations

These include stationary, semimobile or fully mobile inpit Crushing Stations, which are tailored to your specific mine From developing initial process flow sheets and plant layouts to furnishing complete systems, we are ready to help you, regardless of your project sizeSemimobile inpit crusher and conveyor (SMIPCC) systems represent a viable, safer and less fossil fuel dependent alternative however its viability is still highly argued as inadequate methods for the long term projection of system capacity leads to high uncertainty and consequently higher riskContribution to the capacity determination of semi A decisionmaking method to assess the benefits of a semimobile inpit crushing and conveying alternative during the early stages of a mining project Rodrigo Augusto Nunes Yamana Gold Inc Technical Services, Toronto Ontario Canada 3 O Brasil A decisionmaking method to assess