what is agglomeration process in mining MC World

Agglomeration of ore into coarse, porous masses achieves this even distribution of fluids by preventing fine particles from Get P agglomeration of iron ore Mining agglomeration process for iron ore agglomeration process for iron ore 173 views the is the professional mining equipments manufacturer in 2 天前 A researcher, teacher, process developer, designer, vendor, and user of mechanical process technologies, Pietsch held nine patents and is the author of more than 170 papers and five books, including Size Enlargement by Agglomeration, Agglomeration Processes—Phenomena, Technologies, Equipment, and Agglomeration in Industry—Occurrence and What Is Agglomeration? powderbulksolids Iron Mining Processing And Agglomeration Its difficult for us to influence what goes on there and the energy used is significantly higher in the smelting process than it is in the mining process the main source of carbon emissions comes from the use of metallurgical coal as fuel or coke to melt the waste material – also known as gangue – from the ore to extract the ironIron Mining Processing And Agglomeration

Agglomeration metallurgy Britannica

Other articles where Agglomeration is discussed: iron processing: Crushing: Fines, however, must first be agglomerated, which means reforming them into lumps of suitable size by a process called sintering He has worked with many of the mining industry’s top firms, providing feasibility testing, process development, custom equipment and aftermarket services In partnership with FEECO, Le Capitaine has engineered many of the agglomeration drums serving the mining industry today, including copper ore drums for the world’s largest and most Agglomeration technique improves heap leaching The origin of sintering process goes back to 1887 when F Haberlein and T Huntington of England invented the process of agglomeration for sintering of sulphide ores In this process, the sintering was carried with the sintering bed being blown with air from bottom upwards The process was also known as updraft sintering processIron Ore Agglomeration Processes and their Historical

Agglomeration of Particles 911 Metallurgist

Agglomeration is the formation of aggregate by the sticking together of feed and/or recycle materials, and it includes the formation of agglomerate nuclei The main objective in agglomerating fines being the conversion of ores, minerals and chemicals of undesirable fineness into agglomerates characterised by a size consistency desirable for subsequent use or processing In metallurgical Agglomeration increased permeability, percolation rate, and gold recovery Agglomeration permits a very short leaching cycle, which allows for increased gold production Silver Heap Leaching 2000 TPD A silver agglomerationheap leaching Heap Leaching Agglomeration 911 Metallurgist 1 Changes in mining and processing The dramatically increasing cost in mining owing to rising water, power, reagent and steel prices, less favorable ore characteristics, lesser oxide ores and dominance of primary sulfide feeds coupled with economic aspects of sustainability require a large refocus of operations on process mineralogyOre characterization, process mineralogy and lab

agglomeration process minerals Prominer (Shanghai

Agglomeration is a common practice utilized in a wide range of industries, from agriculture to mining to pharmaceuticals This process offers a myriad of advantages, many of which are becoming more and more relevant in today’s global marketApplications of particle agglomeration Powder agglomeration is a necessary and beneficial process in many industries In the mining industry, powdery raw materials like limestone, copper, nickel, cobalt, zinc, gold, and silver are often agglomerated prior to heap leaching Common examples of agglomeration in agriculture are soil and fertilizersExamples of Agglomeration in Powder Processing 2 天前 A researcher, teacher, process developer, designer, vendor, and user of mechanical process technologies, Pietsch held nine patents and is the author of more than 170 papers and five books, including Size Enlargement by Agglomeration, Agglomeration Processes—Phenomena, Technologies, Equipment, and Agglomeration in Industry—Occurrence and What Is Agglomeration? powderbulksolids

Agglomeration » Products » CEMTEC Cement and

Continuous ploughshare mixers CEMTEC's mixers are mainly used for mixing iron ore with additives like water, coke, bentonite, or limestone A good homogenization of these materials is crucial for the following agglomeration process The retention time needed for reaching the required mixing quality depends on the characteristics of the raw material and can be determined at our project plantOther articles where Agglomeration is discussed: iron processing: Crushing: Fines, however, must first be agglomerated, which means reforming them into lumps of suitable size by a process called sinteringAgglomeration metallurgy BritannicaWhile the SXEW process has its roots in copper and is most wellknown in this sector, its significant cost savings and efficiency is pushing it into other markets as well, including cobalt, nickel, zinc, and uranium FEECO has been serving the needs of the mining industry since 1951 with our custom, heavyduty agglomeration drumsBenefits of Agglomeration in an SXEW Process for

Iron Ore Agglomeration Processes and their Historical

The origin of sintering process goes back to 1887 when F Haberlein and T Huntington of England invented the process of agglomeration for sintering of sulphide ores In this process, the sintering was carried with the sintering bed being blown with air from bottom upwards The process was also known as updraft sintering process The industrial agglomeration practice for copper and precious metal ores, type and size of agglomeration equipment (Bouffard, 2005, Moats and Janwong, 2008), drums (design, selection and power requirements) for crushed ore agglomeration process (Miller, 2010) and binder (Lewandowski and Kawatra, 2008, Lewandowski and Kawatra, 2009b) have Crushed ore agglomeration and its control for heap The heap leaching process being employed at Lomati Mine is a commonly used process to extract gold from the ore Generally, the ore is crushed into fine particles before being heaped and sprayed with a leaching solution which liquefies and separates the gold from the oreTHE MINING PROCESS LOMATI MINE

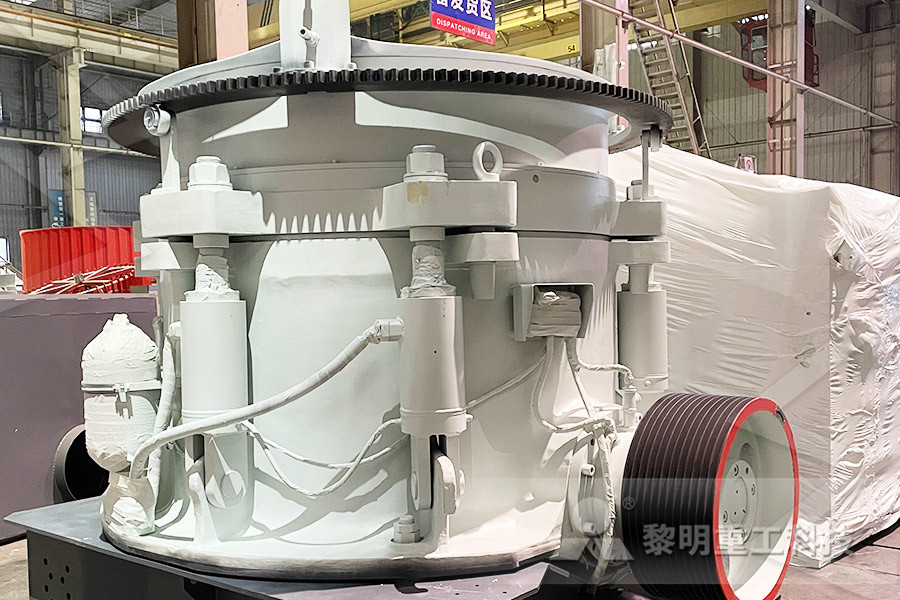

Agglomerators Westpro Machinery

Agglomerators Westpro’s agglomerators have delivered proven performance in crushed ore agglomeration globally for over 30 years Built for the toughest operations, our agglomerators maintain Westpro’s signature robust construction while significantly improving heap leach recoveries in mining Agglomeration of ore into coarse, porous masses achieves this even distribution of fluids by preventing fine particles from Get P agglomeration of iron ore Mining agglomeration process for iron ore agglomeration process for iron ore 173 views the is the professional mining equipments manufacturer in what is agglomeration process in mining MC WorldAgglomeration is a common practice utilized in a wide range of industries, from agriculture to mining to pharmaceuticals This process offers a myriad of advantages, many of which are becoming more and more relevant in today’s global marketagglomeration process minerals Prominer (Shanghai

Examples of Agglomeration in Powder Processing

Applications of particle agglomeration Powder agglomeration is a necessary and beneficial process in many industries In the mining industry, powdery raw materials like limestone, copper, nickel, cobalt, zinc, gold, and silver are often agglomerated prior to heap leachingContinuous ploughshare mixers CEMTEC's mixers are mainly used for mixing iron ore with additives like water, coke, bentonite, or limestone A good homogenization of these materials is crucial for the following agglomeration process The retention time needed for reaching the required mixing quality depends on the characteristics of the raw material and can be determined at our project plantAgglomeration » Products » CEMTEC Cement and Oil agglomeration process United States Patent Abstract: In methods for producing agglomerate particles from aqueous slurries containing from about 10 to about 40 weight percent solids, the solids comprising finely divided carbonaceous solids and finely divided inorganic solids, by mixing the aqueous slurry with oil in a first Oil agglomeration process Consolidation Coal

Briquetting Reclamation Agglomeration Services

Agglomeration is the process of particle size enlargement Most commonly, it refers to the upgrading of material fines into larger particles, such as pellets or granules, but it can also be used to turn sludgelike materials into a dry, granular product Agglomeration is used to transform fine material into manageable, usable and saleable productsMining news and indepth feature articles on the latest mining company deals and projects covering trends in mineral exploration with up to date data on the most mined metal and mineral commodities Receive our newsletter Sign up to our eNewsletter hereFlotation, Agglomeration and Filtering Archives Heap leach mining is an industrial hydrometallurgical process, where the metal contained in an ore body is extracted by dissolution The target mineral is leached with an aqueous solution whereby the mineral is dissolved into what is called a “pregnant” solution which, is then captured and later recovered downstream in the processing lineLearn About the Heap Leaching Process Mining

Iron Ore Pelletizing Process: An Overview

Pelletizing process and raw materials Balling technologies Bonding mechanisms Evolution of binders for iron ore pelletizing Induration technologies Challenges and innovations in iron ore pelletizing 2 Pelletizing process and raw materials The iron ore is mined mostly from open pit deposits through mining operations and the rawCanada’s largest supplier of mineral processing equipment and modern mining solutions Sepro supports both small and large scale mining operations around the worldMineral Processing Equipment Solutions Sepro