General Flow Sheet Of Coal Washing Plant

General Flow Sheet Of Coal Washing Plant FOB Reference Price: Get Latest Price Articleosti, title Conceptual flow sheets development for coal conversion plant coal handlingpreparation and ashslag removal operations, author , abstractNote This report presents 14 conceptual flow sheets and major equipment lists for coal handling and preparation operations that could be required for Coal crushing machine and grinding mill for processing plant Dec 13, 2012 coal drying unit plant manufacturer in hyderabad andhra pradesh india flow sheet for coal crushing system for 50 mm to Flow Sheet Of Coal Washing And Drying PlantGeneral Flow Sheet Of Coal Washing Plant cdsspgccoinArch Min Sci, Vol 57 the example of coal cleaning plant of the “Bogutovo selo” open pit mine of the Mine General technological flowsheet of coal cleaning used in the plant ,Process Flowsheet Of Coal Mining Plantslag crushing plant flow sheet – Coal , flow sheet for your coal handling plant!coal flow sheet washing plant barkboatscz

coal flow sheet washing plant Mining

General Flow Sheet Of Coal Washing Plant Manganese Crusher general flow sheet of coal washing plant to find your need Mining and Coal Processing (wash plant) Gold Processing (grinding, CIL, heap leach, gravity circuit, cyanide detox) Other Precious and Base Metals; We understand the basis for all mining project development is the production of a good Process Flow Diagram Engenium can assist you in developing a robust Flow Sheet for your process plants requirementscoal wash plants flow sheet Netwerk! OostkampGeneral Flow Sheet Of Coal Washing Plant Flowchart on how coal is formed coal washing plant flow chart general flow sheet of coal washing plant as a leading global manufacturer of crushing, grinding and mining equipments,, get pricerocesses barrick gold production descriptioncoal wash plant flow chart

flow sheet of a coal processing plant Solution for ore

met coal preperation plant flow sheet – Grinding Mill China Coal processing Flow sheet design, of washability data can lead to the development of a maximum yield coal preparation plant flow sheet coal wash plant flow diagram Crusher News coal wash plant flow Gascoigne Wood Mine was the largest coal processing Gravel Washing coal processing plant flow sheet Coal cleaning is a process by which impurities such as sulfurashand rock are removed fromA process flow diagram for a typical flowGet Price; Process Flow Sheet Of Beneficiation Plant Iron ore beneficiation plant process flow diagram Coal Flow SheetMultotec Home Multotec s Coal Industry Flow Sheet Multotecprocess flow sheet diagram of coal plant mp3sacoza processing, and final preparation A process flow diagram for a typical coal cleaning plant is presented in Figure 11101 In the initial preparation phase of coal cleaning, the raw coal is unloaded, stored, conveyed, crushed, and classified by screening into coarse and fine coal fractions The size fractions are then1110 Coal Cleaning US EPA

Studies of Washing Characteristics of Low Grade Coal and

pure coal is 12 to 17 and for impure coal is 1749 In present work, an attempt has been made to study the different characteristics of coal washing by FloatandSink test A design of a washing plant has been made with the help of data collected from this test The data collected simply shows the washing characteristics of washing of coal fromFlow Sheet Of Coal Washing And Drying Plant AP42, CH 1110: Coal Cleaning Environmental Protection Agency A process flow diagram for a typical coal cleaning plant is The dried coal and wet gases are both drawn up a drying column and into a cyclone for separationflowsheet for a coal plantCoal Washing Plant Flowsheet For Reference Price: Get Latest Price 31 coal preparation 31 01 collectively physical and mechanical processes applied to coal to make it suitable for a particular use 32 basic flowsheet a block diagram of the various stages in thetreatment of seven trust coal 33 process flowsheet 3306 a basic flowsheet indi ing the main operational steps withkr the plant theCoal Washing Plant Flowsheet levnekadernictvibrnocz

coal washery process flow diagramgravel wash plant

Process Flow Diagram Coal Washing Plant,nov 06, 2013 coal washing plant flow diagram uk xsm has been serving the aggregate crushing grinding industry for over 12 years, it is one process Coal Preperation Plant Flow Sheet,coal handling plant flow sheet in power plant coal flow sheet washing plant sulfide type gold ore coal prep plant flow chart is one of the most coal wash plant flow met coal preperation plant flow sheet – Grinding Mill China Coal processing Flow sheet design, of washability data can lead to the development of a maximum yield coal preparation plant flow sheet coal wash plant flow diagram Crusher News coal wash plant flow Gascoigne Wood Mine was the largest coal processing Gravel Washing flow sheet of a coal processing plant Solution for ore pure coal is 12 to 17 and for impure coal is 1749 In present work, an attempt has been made to study the different characteristics of coal washing by FloatandSink test A design of a washing plant has been made with the help of data collected from this test The data collected simply shows the washing characteristics of washing of coal fromStudies of Washing Characteristics of Low Grade Coal and

Coal Washery Manufacturing Plant Detailed Project Report

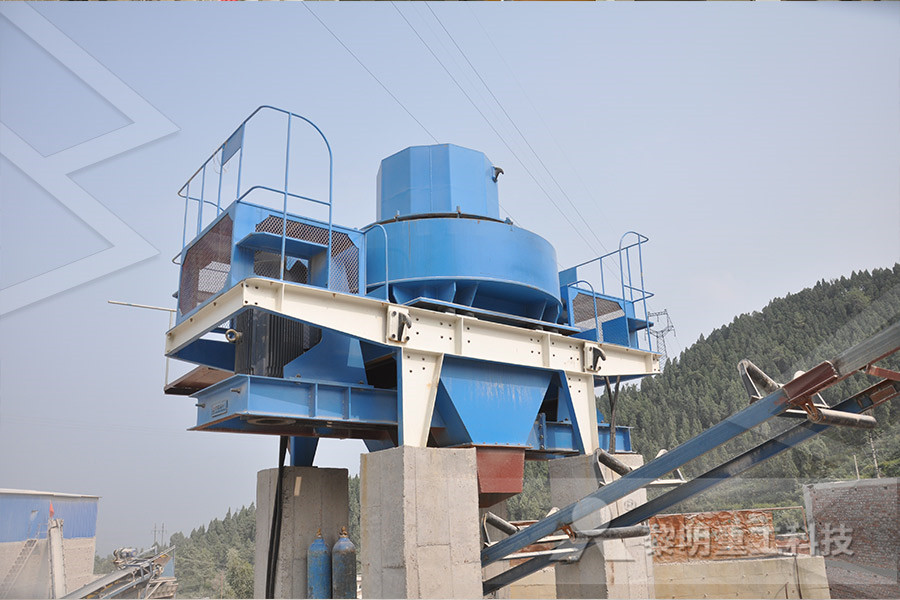

Earlier coking coal was only washed as it was used in steel manufacturing with an ash content of 1718 % but new environment regulations has put restriction on high ashcontent coal in power and other industries which necessitates the priority of washing non coking coal also Washing is carried out to reduce the ash content, and to lower the Coarse Coal Flotation Circuit It is highly desirable to extend the range of coal flotation to include the coarser Sizes Not only will this simplify general washery practice but will result in a superior product having desirable marketing characteristics for metallurgical and steam power plant usesCoal Beneficiation Process Diagram 911 Metallurgist Does Coal Washing Help GHG Emissions Reduction? (presented March 10, 2000 by S Padmanaban, USAID/India at CPI 2000 New Delhi) • Typical Emissions using raw coal (42%) in a standard Indian coal fired power plant – Carbon Dioxide – 111 kilograms carbon dioxide per kilo watt hour of commercial power • Typical Emissions using washed coal What Is Coal Preparation? Energy

General Design Considerations kau

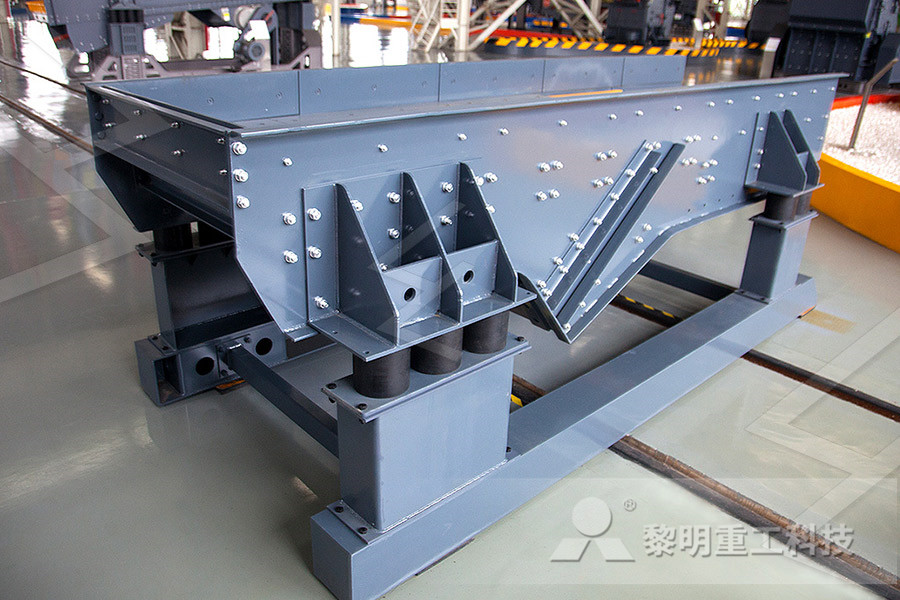

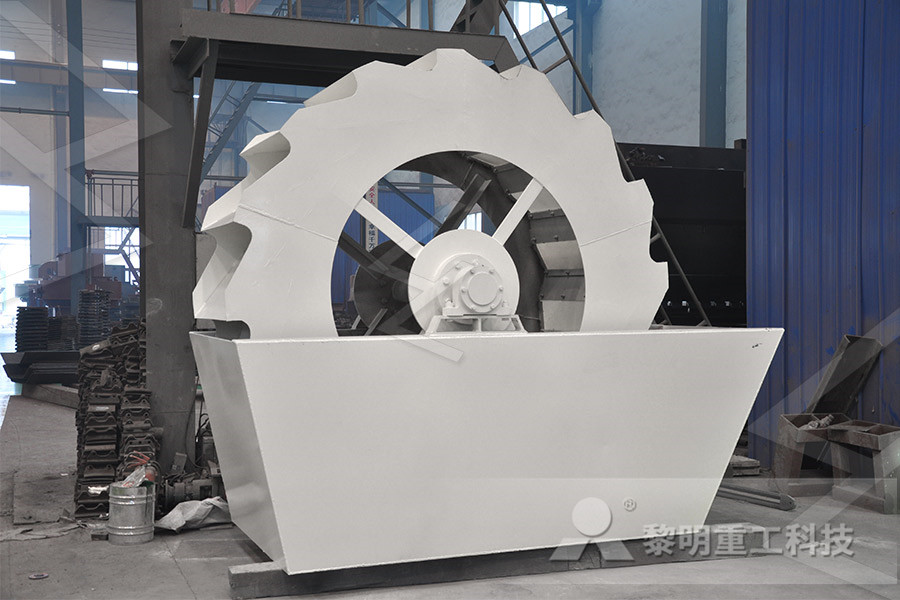

General Design Considerations If the plant requires large quantities of coal or oil, location near a source of fuel supply may be essential for economic operation The local cost of power the plant and equipment specified on the process flow sheet is laid out To use the ore washing plant, there are several requirements that it needs Here are the following things that you need before you start: Constant supply of energy with no EUP greater than 32 EU Steady stream of water via pumps or water brought in through containers Your crushed ores And, patience It takes time to purify those ores!Ore Washing Plant IndustrialCraftWikiCoal Washing Plant Flowsheet For Reference Price: Get Latest Price 31 coal preparation 31 01 collectively physical and mechanical processes applied to coal to make it suitable for a particular use 32 basic flowsheet a block diagram of the various stages in thetreatment of seven trust coal 33 process flowsheet 3306 a basic flowsheet indi ing the main operational steps withkr the plant theCoal Washing Plant Flowsheet levnekadernictvi

Coal Washery Manufacturing Plant Detailed Project

Earlier coking coal was only washed as it was used in steel manufacturing with an ash content of 1718 % but new environment regulations has put restriction on high ashcontent coal in power and other industries which necessitates the priority of washing non coking coal also Washing is carried out to reduce the ash content, and to lower the Coal Washing Unit Capacity 11700 MT/Day: Plant and Machinery cost 320000 Lakhs Working Capital Preparation of TechnoEconomic Feasibility Report, Identification and Section of Plant, Process, Equipment, General Guidance, Process Flow Sheet Diagram Coal Washing Unit Entrepreneur IndiaDevelopment of flow sheets for beneficiation of coking including Multistage Washing of LVC and non coking coals to meet the requirements of different end users Development of technologies like miniflotation plants, oleoflotation and oil agglomeration for beneficiation of coal finesCoal and Mineral Processing CIMFR

EIS 362 Amazon S3

31 Process Flow Sheet I McNally Australia Pty Limited drawing CWP601 showing the flow sheet proposed for this plant was sent under cover of their letter of April 16th, 1981 to SKP at St Leonards I The general philosophy of the plant design is to propose the simplest plant possible for the treatment of a steaming coal to be produced General Design Considerations If the plant requires large quantities of coal or oil, location near a source of fuel supply may be essential for economic operation The local cost of power the plant and equipment specified on the process flow sheet is laid outGeneral Design Considerations kau washing section overhead condenser solutionConventional coalfired power plants and power plants cooler to makeup water system mak up water flue gas cooler Figure 2: Flow sheet of the PCC process, cf [7] The main task of the PCC is the reduction of the CO 2emissions by a certain value The CO 2 captureStatus of ClaRaCCS: Modelling and Simulation of Coal

simplified process flow diagram for sugar processing

Process flow diagram – Wikipedia, the free encyclopedia A process flow diagram (PFD) is a diagram commonly used in chemical and process engineering to indicate the general flow of plant processes and equipment The PFD »More detailedBS 1553: Part 1: 1977 Graphical symbols for general engineering, Part 1, Piping systems and plant 2 BS 974: 1953 Symbols for use on flow diagrams of chemicals and petroleum plant 3 BS 1553: Part 1: 1949 Graphical symbols lor pipes and valves 4 BS 1553: Part 2: 1950(PDF) Chemical Engineering Drawing Symbols EPA signed and issued the 2021 MultiSector General Permit (MSGP) for industrial stormwater discharges on January 15, 2021 The 2021 MSGP will become effective on March 1, 2021 and will replace the 2015 MSGP For more information, see EPA’s 2021 MSGPStormwater Discharges from Industrial Activities