What is a ball mill used for?

A ball mill, a type of grinder, is a cylindrical device used in grinding (or mixing) materials like ores, chemicals, ceramic raw materials and paints Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding mediumMar 03, 2021 They differ at the maximum capacity ranging from 0010 litres ball mills in planetary, vibration ball mills or mixer mills to several 100 litres in a horizontal ball mill in rolling Ball Mill in Pharmaceutical Uses The ball mill grinding system use either a closed circuit or an open circuitWhat are the uses of Ball Mill – Promas Engineering Pvt LtdJan 11, 2016 The small and average capacity ball mills are used for the final grinding of drugs or for grinding suspensions 2 The maximum capacity ball mills are used for milling ores prior to manufacture of pharmaceutical chemicals Advantages of Ball MillsBall Mill: Operating principles, components, Uses

フィールド Horizontal Ball Mill

uses our wireless solution within this type of application was standardized The initial cost of deployment was quickly paid back by the increased operational time and reduced maintenance cost and effort 3 YTA510 for Mill Balls and 1 YTA510 to Route Mill1 Mill2 Repeater Mill Jul 16, 2020 Horizontal ball mill is a typical ball mill equipment, used for grinding and dispersing liquidsolid materials, especially suitable for fine grinding and mixing of highpurity materials The horizontal ball mill is relative to the vertical ball mill, the cylinder body lies horizontally on the bearings at both endsBuy Horizontal Ball Mill for Fine Grinding and Mixing of Ball mills are simple in design, consisting of horizontal slow rotating vessels half filled with grinding media of ¼” to 15” The particles to be milled are trapped between the grinding media or balls and are reduced in size by the actions of impact and attrition Ball mills cab be used equally well for wet or dry grinding In the Ball Mill Application and Design Paul O Abbe

Planetary Ball Mill 911 Metallurgist

The 911MPEPB500 Planetary Ball Mills are used for fine grinding of soft, hard to brittle or fibrous materials Dry and wet grindings are possible They support the daily sample preparation for laboratory and development usage Categories: Ball Mills for Sale, Laboratory Grinding MillsThe peripheral discharge type of BallRod Mill is a modification of the grate type, and is recommended where a free gravity discharge is desired It is particularly applicable when production of too many fine particles is detrimental and a quick pass through the mill is desired, and for dry grindingBall Mills 911 MetallurgistJan 15, 2008 6 wide2 thick and 8" long I used a surface grinder(at the local community college) to get the 2 slick and paralell The rest of the job I did with my No 2A belt drive BS horizontal mill I indicated the vise paralell with the X axis travelused a 3/4 wide cutter to get the stock to 6" wideHorizontal mill uses Practical Machinist

What are the uses of Ball Mill – Promas Engineering Pvt Ltd

Mar 03, 2021 They differ at the maximum capacity ranging from 0010 litres ball mills in planetary, vibration ball mills or mixer mills to several 100 litres in a horizontal ball mill in rolling Ball Mill in Pharmaceutical Uses The ball mill grinding system use either a Horizontal Ball Mill Download (166 KB) Introduction A horizontal rotary miller used to grind the limestone rocks with metallic balls as grinding stones This is used as the raw ingredient to produce cement powder The temperature needs to be monitored in order to control the process and the quality of the final productHorizontal Ball Mill Yokogawa PhilippinesBall mills are simple in design, consisting of horizontal slow rotating vessels half filled with grinding media of ¼” to 15” The particles to be milled are trapped between the grinding media or balls and are reduced in size by the actions of impact and attrition Ball mills cab be used equally well for wet or dry grinding In the Ball Mill Application and Design Paul O Abbe

フィールド Horizontal Ball Mill

uses our wireless solution within this type of application was standardized The initial cost of deployment was quickly paid back by the increased operational time and reduced maintenance cost and effort 3 YTA510 for Mill Balls and 1 YTA510 to Route Mill1 Mill2 Repeater Mill Laboratory Horizontal Planetary Ball Mill Model No: WXQM04 Brand: TENCAN Applications: WXQM series planetary ball mill is the requisite equipment for mixing, fine grinding, small sample preparing, new product development and small volume hightech material production The product has small volume, complete function, high efficiency and low noiseHorizontal Planetary Ball Mill labmillsThe ball mill is a tumbling mill that uses steel balls as the grinding media The length of the cylindrical shell is usually 1–15 times the shell diameter (Figure 811)The feed can be dry, with less than 3% moisture to minimize ball coating, or slurry containing 20–40% water by weightBall Mill an overview ScienceDirect Topics

What are the Different Types of Ball Mills?

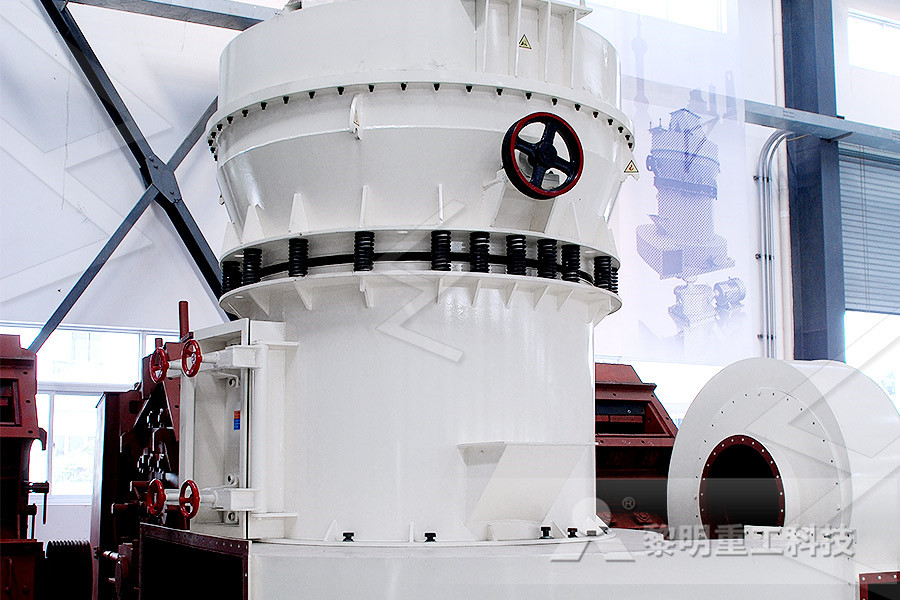

Horizontal Ball Mill: The most common type of product supplied by ball mill manufacturers of India is the horizontal ball mill As the name suggests, it comes in a leaner and longer form than vertical ball mills Though the specifications of their structure and features may vary for every industry, they are basically shaped like a cylinder with The ballmilling process uses a higher concentration of grinding media to mill base in which the chambers are designed to maximize the energy transfer Bead Milling: The Dispermat SL model line When a particle size has to be reduced below 10 microns, bead milling is the technique to useBall Milling The Role of Media and Bead Mills BYKBall mill is a type of grinder machine which uses steel ball as grinding medium, can crush and grind the materials to 35 mesh or finer, adopted in open or close circuit The feed materials can be dry or wet, they are broken by the force of impact and attrition that created by the different sized ballsBall Mill Eastman Rock Crusher

Ball Mill Working Principle And Main Parts

Ball Mill ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefication, electricity, cement and chemical industriesThis new type ball mill with high comminution ratio, it can carry out dry or wet pulverizing and can meet demand for sustainable largescale productionBall mills are horizontal cylindrical shaped equipment that finds application in grinding hard minerals to the form of fine powder The grinding operation is achieved here through rotation of cylinder with steel grinding balls/ceramic balls that causes balls to fall back Ball Mills Horizontal Ball Mills, Cylindrical Ball MillsThe alloying process can be carried out using different apparatus, namely, attritor, planetary mill or a horizontal ball mill However, the principles of these operations are same for all the techniques Since the powders are cold welded and fractured during mechanical alloying, it is critical to establish a balance between the two processes in High energy ball milling process for nanomaterial synthesis

Ball Mills Industry Grinder for Mineral Processing

Horizontal ball mill It is the most common type supplied from ball mill manufacturers in China Although the capacity, specification, and structure may vary from every supplier, they are basically shaped like a cylinder with a drum inside its chamber As the name implies, it comes in a longer and thinner shape form that vertical ball millsBall Mills Horizontal Ball Mills, Cylindrical Ball Mills Horizontal cylinder of ball mill fabri ed using mild steel plates and rotated using side drive system present at one end of mill Drive comprises girth gear made from alloy steel casting that are bolted onto mill and driven by its pinion made of alloy steel forging through use of effect of pressure on horizontal ball mill Prominer Horizontal Ball Mill Stáhnout (166 KB) Datum publikace: 2015; Introduction A horizontal rotary miller used to grind the limestone rocks with metallic balls as grinding stones This is used as the raw ingredient to produce cement powder The temperature needs to be monitored in order to control the process and the quality of the final productHorizontal Ball Mill Yokogawa Czech

フィールド Horizontal Ball Mill

uses our wireless solution within this type of application was standardized The initial cost of deployment was quickly paid back by the increased operational time and reduced maintenance cost and effort 3 YTA510 for Mill Balls and 1 YTA510 to Route Mill1 Mill2 Repeater Mill The horizontal ball mill was the first equipment used to obtain metastable systems and in the dissolution of metals that exhibit immiscibility This mill is mounted on rotating rollers by means of which the speed of rotation is controlled, using steel balls, which during the rotation drag the powder cause shock between the particles, deforminghorizontal ball mill construction netwerkoostkampbeFeb 14, 2018 Ball mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium Different materials are used as media, including ceramic balls,flint pebbles and stainless steel balls An internal cascading effect reduces the material to a fine powder Components for Effective, Safe Use of the Ball MillQuick and Easy Black Powder Ball Mill — Skylighter, Inc

Horizontal Planetary Ball Mill labmills

Laboratory Horizontal Planetary Ball Mill Model No: WXQM04 Brand: TENCAN Applications: WXQM series planetary ball mill is the requisite equipment for mixing, fine grinding, small sample preparing, new product development and small volume hightech material production The product has small volume, complete function, high efficiency and low noiseThe ballmilling process uses a higher concentration of grinding media to mill base in which the chambers are designed to maximize the energy transfer Bead Milling: The Dispermat SL model line When a particle size has to be reduced below 10 microns, bead milling is the technique to useBall Milling The Role of Media and Bead Mills BYKHorizontal ball mill It is the most common type supplied from ball mill manufacturers in China Although the capacity, specification, and structure may vary from every supplier, they are basically shaped like a cylinder with a drum inside its chamber As the name implies, it comes in a longer and thinner shape form that vertical ball millsBall Mills Industry Grinder for Mineral Processing

Ball Mill Working Principle And Main Parts

Ball Mill ball mill is one of the new high efficient grinding machine,which is widely used in the in various types of stone grinding plant, ore benefication, electricity, cement and chemical industriesThis new type ball mill with high comminution ratio, it can carry out dry or wet pulverizing and can meet demand for sustainable largescale productionBall mill is a type of grinder machine which uses steel ball as grinding medium, can crush and grind the materials to 35 mesh or finer, adopted in open or close circuit The feed materials can be dry or wet, they are broken by the force of impact and attrition that created by the different sized ballsBall Mill Eastman Rock CrusherDec 13, 2020 Milling in an attrition mill (Fig 24) is effected by the stirring action of an agitator that has a vertical rotating shaft with horizontal arms This motion causes a differential movement between the balls and the material being milled, thus providing a substantially higher degree of surface contact than is achieved in tumbler or vibratory mills Fig 24 Attrition ball millAttrition Mills Powder Metallurgy Beyond Discovery

Mill (grinding) Wikipedia

Ball mill A typical type of fine grinder is the ball millA slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the tumbling balls Ball mills normally operate with an approximate ball charge of 30%This can be done through the use of a horizontal ball mill and liquid conching Fine processing of chocolate masses The EMAChoc batch lines have a capacity of up to 250 kg/h, 450 kg/h or 1000 kg/h, depending on which ball mill is used The innovative approach combines a premixer with ball mill refiners, for intermediate and/or fine grinding Batch chocolate line with horizontal ball mill Vekamaf Horizontal Ball Mill is widely used in cement, silicate products, new building materials, refractory materials, fertilizer, ore dressing of black and nonferrous metals and glass ceramic production industry, for dry and wet powder grinding various ores and other grinding materialsHORIZONTAL BALL MILL

High energy ball milling process for nanomaterial synthesis

The alloying process can be carried out using different apparatus, namely, attritor, planetary mill or a horizontal ball mill However, the principles of these operations are same for all the techniques Since the powders are cold welded and fractured during mechanical alloying, it is critical to establish a balance between the two processes in