Vertical Roller Mill,Verical Roller Mill Types

Vertical roller mill has become the first choice for the cement industry, raw material grinding, it is estimated there are more than 600 sets of production Large With roller press grinding cement grinding mill, also has the problem of low temperature ratio So, with roller press for cement finish grinding, is more suitable What are the vertical mill cement finish grindingVertical Roller Mills In Vertical Roller mill 2 4 rollers (lined with replaceable liners) turning on their axles press on a rotating grinding table (lined with Cement Grinding Cement Plant Optimization

Vertical roller mill optimisation CemNet

Apr 05, 2017 Vertical roller mills (VRMs) have become the equipment of choice for raw and solid fuel grinding in cement factories Increasingly modern cement plants also use Apr 01, 2017 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power Operational parameters affecting the vertical roller mill • Vertical roller mill (VRM) • Ring roller mill or Horo mill Even though there are various types of systems available for cement grinding, ball mills PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

Vertical Roller Mill,Verical Roller Mill Types

Vertical roller mill has become the first choice for the cement industry, raw material grinding, it is estimated there are more than 600 sets of production Large vertical mill capacity has reached 600t / h, the transmission power of 5000KW In the early 1990s, cement grinding mill stand areas has progressed, there are many large mill productioncement grinding in a vertical roller mill Numerical Study Of The Flow Field In A Vertical Roller Mill Scientific Netthe vertical roller mill is a type of grinding machine for raw material processing and cement grinding in the cement manufacturing process recent years, the vrm cement mill has been equipped in more and more cement plants around the world because of its features like high cement grinding in a vertical roller millProven commercially, the OK mill is the premier roller mill for finish grinding of Portland cement, slag and blended cements The OK mill's grinding efficiency can contribute significantly to plant profitability and competitiveness Roller profile The patented grooved roller profile has two grinding zones: an OK™ mill The most reliable and efficient mill for raw and

Cement Milling Understanding Cement

Vertical roller mills (VRMs) are the main alternative means of grinding the clinker and are increasingly being used For a quick introduction to VRMs see, for example, this advertisement on Youtube for an FL Smidth VRM As part of the grinding process, calcium sulfate is added as a set regulator, usually in the form of gypsum (CaSO 42H 2 O)The described mill types are in successful operation at various of Shree Cement’s locations and these repeatedly ordered mills reflect the satisfaction of the customer, who is currently running 24 Pfeiffer millsThe MVR mill with its 6 actively redundant grinding rollers has proven particularly successful for the finishgrinding of cementMVR vertical roller mills for cement and raw material The particularly efficient MVR and MPS vertical roller mills offer UltraTech many advantages and are used for the finish grinding of cement raw material, fuel and cements The cooperation between UltraTech Cement Ltd and Gebr Pfeiffer is based on the understanding of not only being a customer or supplier, but to achieve common goals in Nine further vertical roller mills from Gebr Pfeiffer for

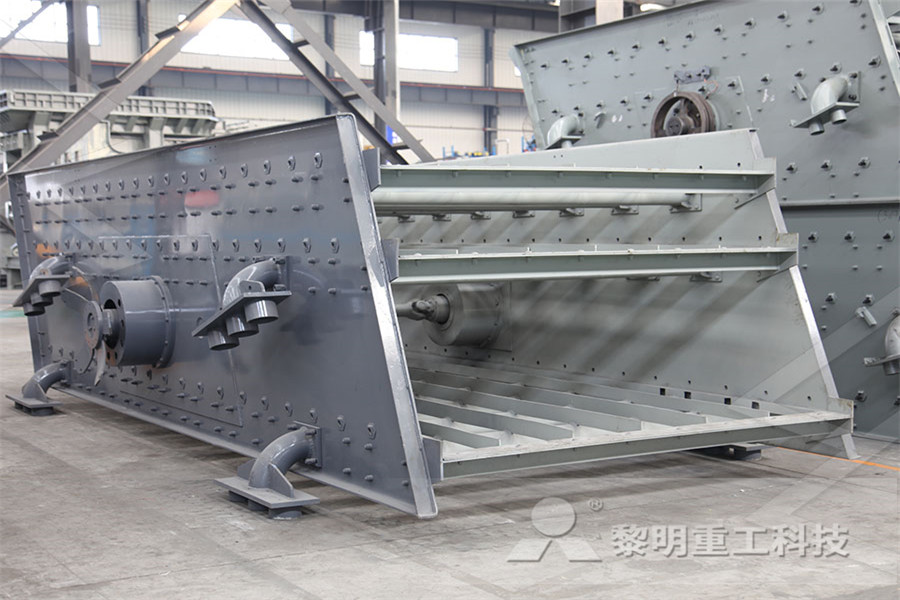

Cement Mill Vertical Mill Manufacturer SINOMALY

SINOMALY provides various types of Cement Mill, Clinker Mills, which are designed for use in grinding mill production lines with output levels of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d, 8000t/d Cement pregrinding is a production process used to grind raw material to a specified size so that it can be more easily processed by a final The effect of grinding aids on the comminution of cement is based on the dispersion of fine particles It is a misunderstanding that grinding aids for vertical roller mills (VRMs) should stabilise the material bed between the rollers and the table by adhesive forces between the particlesProgress with Grinding Aids for Vertical Roller MillsA cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill Wikipedia

How Vertical Grinding Mills Work (Coal Pulverizer Example

Jun 14, 2019 Learn about vertical grinding mills and coal pulverizers! We look at all of the vertical grinding mill’s main components, how it works and some of its designNov 24, 1992 A method for finishgrinding cement in a roller mill plant, characterized in, that water is added to the material which is to be ground in the roller mill 2 A method according to claim 1, characterized in, that water is added to the material prior to its introduction into the roller mill eg vertical mills in which the grinding rollers Method for finishgrinding cement in a roller mill plant Vertical roller mill is mainly used for grinding raw meal, clinker, GGBFS(Ground Granulated Blast Furnace Slag), iron ore, limestone, coal powder, coke powder, coal gangue, fly ash, volcanic ash, gypsum, calcite, pyrophyllite, quartz, clay, sandstone, bauxite and other processing industry related to metal and nonmetal mineVertical Roller Mill GGBSCement Plant,cement grinding

LOESCHEMILLS

• cement industry: Nghi Son, Vietnam, 1998,Guangzhou, China, 2005 Loesche developed the 4roller coal grinding mill with four tried and tested modules for throughputs over 150 t/h The development was first realised in 1970 for grinding mills in the cement industry This number of rollers also enables operation with only one pair of rollers In order to better study the cement vertical mill, ball mill, roller press in the application of the domestic actual situation, some industry experts for the comparative study of the many several grinding equipment, the final result, cement vertical mill finish grinding in power consumption, investment, product performance and other aspects is grinding mill in cement industry,grinding machine manufacturerVertical roller mill has become the first choice for the cement industry, raw material grinding, it is estimated there are more than 600 sets of production Large vertical mill capacity has reached 600t / h, the transmission power of 5000KW In the early 1990s, cement grinding mill stand areas has progressed, there are many large mill productionVertical Roller Mill,Verical Roller Mill Types

OK™ mill The most reliable and efficient mill for raw and

Proven commercially, the OK mill is the premier roller mill for finish grinding of Portland cement, slag and blended cements The OK mill's grinding efficiency can contribute significantly to plant profitability and competitiveness Roller profile The patented grooved roller profile has two grinding zones: an Vertical roller mill is mainly used for grinding raw meal, clinker, GGBFS(Ground Granulated Blast Furnace Slag), iron ore, limestone, coal powder, coke powder, coal gangue, fly ash, volcanic ash, gypsum, calcite, pyrophyllite, quartz, clay, sandstone, bauxite and other processing industry related to metal and nonmetal mineVertical Roller Mill GGBSCement Plant,cement grinding The effect of grinding aids on the comminution of cement is based on the dispersion of fine particles It is a misunderstanding that grinding aids for vertical roller mills (VRMs) should stabilise the material bed between the rollers and the table by adhesive forces between the particlesProgress with Grinding Aids for Vertical Roller Mills

Vertical Roller Mill Cement Grinding

Vertical Roller Mills for Finish Grinding the Industrial Efficiency Ball mills, that are commonly used for finish grinding, have high energy demands, Here is our listing of Vertical Roller Mills for grinding cement raw materials, followed by Dry Raw Ball Mills All are available for immediate deliverySINOMALY provides various types of Cement Mill, Clinker Mills, which are designed for use in grinding mill production lines with output levels of 2500t/d, 3200t/d, 4000t/d, 5000t/d, 6000t/d, 8000t/d Cement pregrinding is a production process used to grind raw material to a specified size so that it can be more easily processed by a final Cement Mill Vertical Mill Manufacturer SINOMALYNov 24, 1992 A method for finishgrinding cement in a roller mill plant, characterized in, that water is added to the material which is to be ground in the roller mill 2 A method according to claim 1, characterized in, that water is added to the material prior to its introduction into the roller mill eg vertical mills in which the grinding rollers Method for finishgrinding cement in a roller mill plant

How Vertical Grinding Mills Work (Coal Pulverizer Example

Jun 14, 2019 Learn about vertical grinding mills and coal pulverizers! We look at all of the vertical grinding mill’s main components, how it works and some of its designJul 31, 2012 Cement vertical roller mill finish grinding technology research and application smilewei005 Gearbox/Gear Reducer/Vertical roller mill reducer GuoVincent Vertical roller grinding mill0601 Shanghai Clirik Mahcinery Case Study RAW MILL GRINDING ROLLER 13 Rahul Mundra Improving the Performance of Loesche´s Vertical Mill 3 at Finish Mill No 7 Feed Conveyor C024 Baghouse 6025 Cement Conveyor C025 Baghouse 6026 Cement Bucket Elevator C026 Baghouse 6027 Finish Grinding Vertical Roller Mill C027 Baghouse 6028 Cement Conveyor from Silos C028 Baghouse 6030 Kiln No 6 Gypsum Silo Anhydrite C030 Baghouse 6031 Kiln No 6 Gypsum Silo Zynt 40 CFR 5221; 40 CFR Part 63,Part 70 Operating Permit Amendment epdgeorgiagov

Cement Vertical Roller Mill gwmcn

Cement Vertical roller mill (VRM) is mainly used to grind cement clinker into fine powder during cement production, which can also be used to grind various materials such as calcite, marble, limestone, coarse whiting, talc, barite and dolomite etc Application : Cement Plant, Cl• cement industry: Nghi Son, Vietnam, 1998,Guangzhou, China, 2005 Loesche developed the 4roller coal grinding mill with four tried and tested modules for throughputs over 150 t/h The development was first realised in 1970 for grinding mills in the cement industry This number of rollers also enables operation with only one pair of rollers LOESCHEMILLSThe difference between ball mill and vertical mill in cement grinding Over the last three decades the vertical roller mill has become the preferred ball mill for grinding of raw materials The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill systemThe difference between ball mill and vertical mill in

Grinding trends in the cement industry Cement Lime Gypsum

Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 % It is somewhat surprising that the number of different grinding processes and mill types used by the