size of granite crushing and sizing circuit of aggregate

size of granite crushing and sizing circuit of aggregate production Mining crushers mainly include jaw crusher, cone crusher, impact crusher, mobile crusher for crushing stone, rock, quarry materials in The available grain size from granite stone crushing screening Primary granite crusher in the crushing circuit Go to Product Center crushing screening metal screw wash nz, Production Market; Factory; size of granite crushing and sizing circuit of aggregate granite jaw crusher india; Go to Product Centersize of granite crushing and sizing circuit of aggregate aggregate physical properties, and, in particular, gradation (size control) Establishing a stable production process may reduce variability of the product EXTRACTION With the exception of slag and other manufactured aggregates most materials for aggregate production come from bedrock or unconsolidated deposits5 Aggregate Production in

AP42 Section 11192 Crushed Stone Processing and

screens and classifiers (for the production of manufactured sand) Some stone crushing plants produce manufactured sand This is a smallsized rock product with a maximum size of 050 centimeters (3/16 th inch) Crushed stone from the tertiary sizing screen is sized in a vibrating inclined screen (fines screen) with relatively small mesh sizesSep 02, 2019 Today, primary crushing is viewed as more important within the balance of production and proper sizing needs The size and type of the primary crusher should be coordinated with the type of stone, drilling and blasting patterns, and the size of the loading machine Most operations will use a gyratory, jaw or impact crusher for primary crushingPQ University Lesson 7 Crushing Secondary Breaking crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001) • More attention is being paid to the impact on crushing circuit design caused by variations in ore characteristics, size distribution, moisture content, ore grade and climaticCrushing Plant Design and Layout Considerations

5 Aggregate Production in

aggregate physical properties, and, in particular, gradation (size control) Establishing a stable production process may reduce variability of the product EXTRACTION With the exception of slag and other manufactured aggregates most materials for aggregate production come from bedrock or unconsolidated depositsSep 02, 2019 Today, primary crushing is viewed as more important within the balance of production and proper sizing needs The size and type of the primary crusher should be coordinated with the type of stone, drilling and blasting patterns, and the size of the loading machine Most operations will use a gyratory, jaw or impact crusher for primary crushingPQ University Lesson 7 Crushing Secondary Breaking ii Fine aggregate (sand): Aggregates passing No4 (475 mm) sieve and predominately retained on the No 200 (75 μm) sieve In accordance with sources: i Natural aggregates: This kind of aggregate is taken from natural deposits without changing their nature during the process of production such as crushing and grindingCOST EVALUATION OF PRODUCING DIFFERENT

Aggregates for Concrete

aggregate size numbers Fine aggregate or sand has only one range of particle sizes for general construction and highway work The grading and grading limits are usually expressed as the percentage of material passing each sieve Fig 56 shows these limits for fine aggregate and for one size of coarse aggregateReview external factors (type of material, amount of near size in the material, shape of material) • Review the screen sizing formula and the effects that each of the above can have on the sizing process • Review speed, stroke and slope • Media options available to today's producers and there applications •Principles of Screening and Sizing 911 MetallurgistClassification of Aggregates Based on Size Aggregates are available in nature in different sizes The size of aggregate used may be related to the mix proportions, type of work etc the size distribution of aggregates is called grading of aggregates Following are the classification of aggregates based on size: Aggregates are classified into 2 types according to sizeClassification of Aggregates Based on Size and Shape

Aggregates Martin Marietta

Common Sizes 3/16" and Smaller; Other DOT and Special Sizes Available Designations Screenings, Concrete Sand, Mortar Sand, Asphalt Sand, Rock Dust, Rock Powder Common Applications Concrete Asphalt MSE Wall Backfill Select Backfill RefractorsMay 13, 2019 To apply what this means to your crusher, operations produce the exact sizes in the reduction process that their market demands In the past, quarries produced a range of singlesize aggregate products – up to 40 mm in size Still, the trend for highly specified aggregate means products are increasingly finerTips to maximize crushing efficiency Pit Quarry : Pit Aug 11, 2018 When the aggregate is sieved through 475mm sieve, the aggregate retained is called coarse aggregate Gravel, cobble and boulders come under this category The maximum size aggregate used may be dependent upon some conditions In general, 40mm size aggregate used for normal strengths and 20mm size is used for high strength concreteDifferent Types Sizes of Aggregate for Concrete

Ore, Rock Aggregate Screening (Complete Guide)

Jun 20, 2016 AZ Guide to Screening Ore, Rock Aggregate A simple definition of a “screen” is a machine with surface(s) used to classify materials by size Screening is defined as “The mechanical process which accomplishes a division of particles on the basis of size and their acceptance or rejection by a screening surface”Aug 01, 2012 The crushed materials will be transferred to the vibrating screen, and separated to different sizes Those aggregate with suitable size will be transferred to the final product pile and those with unsuitable size will be transferred to the Impact Crusher for recrushing It forms a closed circuit Crusher for granite mining, quarrying plant News The larger sized stones pass through to the final crushing stages where they are fed through a series of cone crushers and screens The output from the final cone crushers is conveyed to a screen house where large multiple deck screens sort the crushed stone into the required aggregate sizesQuarrying Process And Quarry Products

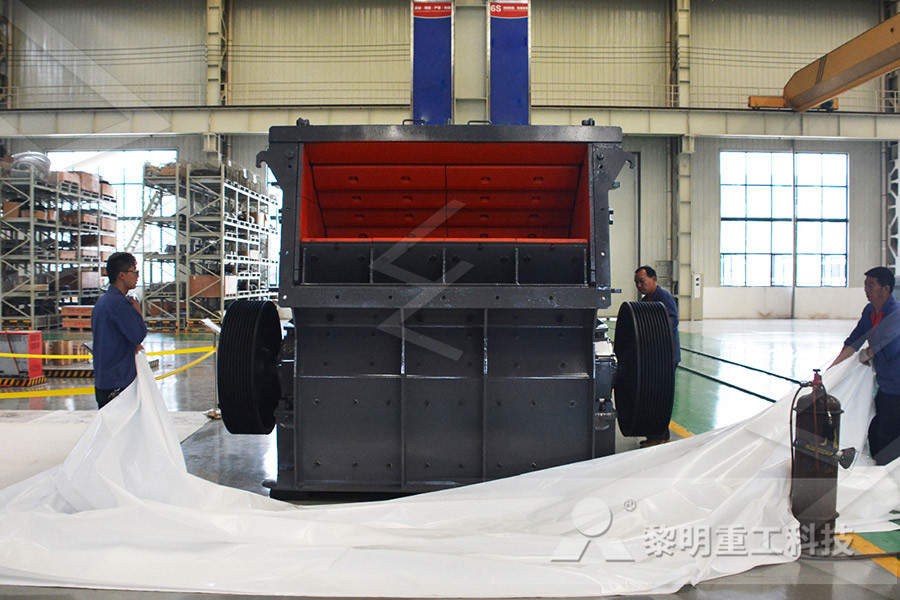

CRUSHING SCREENING Crushing and Screening

quarries, mining facilities and industrial facilities We offer a variety of sizes and styles in three different crushing groups—primary, secondary and tertiary—which are used to crush materials with dimensions ranging from 1mm to 1000mm and vary depending on capacity, hardness and size of Construction aggregate, or simply aggregate, is a broad category of coarse to mediumgrained particulate material used in construction, including sand, gravel, crushed stone, slag, recycled concrete and geosynthetic aggregatesAggregates are the most mined materials in the world Aggregates are a component of composite materials such as concrete and asphalt concrete; the aggregate serves as Construction aggregate WikipediaSep 02, 2019 Today, primary crushing is viewed as more important within the balance of production and proper sizing needs The size and type of the primary crusher should be coordinated with the type of stone, drilling and blasting patterns, and the size of the loading machine Most operations will use a gyratory, jaw or impact crusher for primary crushingPQ University Lesson 7 Crushing Secondary Breaking

CRUSHING SCREENING Crushing and Screening

quarries, mining facilities and industrial facilities We offer a variety of sizes and styles in three different crushing groups—primary, secondary and tertiary—which are used to crush materials with dimensions ranging from 1mm to 1000mm and vary depending on capacity, hardness and size of Review external factors (type of material, amount of near size in the material, shape of material) • Review the screen sizing formula and the effects that each of the above can have on the sizing process • Review speed, stroke and slope • Media options available to today's producers and there applications •Principles of Screening and Sizing 911 MetallurgistSandstone production line is also called Aggregate Plant It is a special designed plant for producing sand and stone for construction The finished products include various sizes stone and artificial sand, which is equivalent to the combination of stone crushing line and sand making lineHow To Design Aggregate Making Plant MC

Crusher for granite mining, quarrying plant News

Aug 01, 2012 The crushed materials will be transferred to the vibrating screen, and separated to different sizes Those aggregate with suitable size will be transferred to the final product pile and those with unsuitable size will be transferred to the Impact Crusher for recrushing It forms a closed circuit Classification of Aggregates Based on Size Aggregates are available in nature in different sizes The size of aggregate used may be related to the mix proportions, type of work etc the size distribution of aggregates is called grading of aggregates Following are the classification of aggregates based on size: Aggregates are classified into 2 types according to sizeClassification of Aggregates Based on Size and Shape May 13, 2019 To apply what this means to your crusher, operations produce the exact sizes in the reduction process that their market demands In the past, quarries produced a range of singlesize aggregate products – up to 40 mm in size Still, the trend for highly specified aggregate means products are increasingly finerTips to maximize crushing efficiency Pit Quarry : Pit

Aggregates Overview Aggregates, Sand, and Gravel

Its unique crushing action provides excellent capacity, high reduction, and good product cubicity for the production of highquality aggregate and subbase materials A level probe over the feed ring regulates the feed belt to ensure the cone chamber is choke fed, essential for maximum reduction, manganese life, and optimal product shapeA larger size, 40mm, is more common in mass concrete • Larger aggregate diameters reduce the quantity of cement and water needed 20 mm aggregate Common aggregates • Crushed Stone and Manufactured Sand Stone is quarried, crushed and ground to produce a variety of sizes of aggregate to fit both ‘coarse’ and ‘fine’ specifications Aggregates for ConcreteJun 20, 2016 AZ Guide to Screening Ore, Rock Aggregate A simple definition of a “screen” is a machine with surface(s) used to classify materials by size Screening is defined as “The mechanical process which accomplishes a division of particles on the basis of size and their acceptance or rejection by a screening surface”Ore, Rock Aggregate Screening (Complete Guide)

Use of Recycled Concrete Materials in Base/Subbase

Dec 02, 2017 Crushing and Screening (Sizing) •A screen is almost always used to properly size the material –Allows for increased production by returning oversized material to the crusher –Can be used to split material on a midsized sieve (eg 3/8”) when specifications requireAggregate is classified by particle size and consistency There are two basic types: sand and gravel (sometimes called natural stone) and crushed stone More recently a third type of aggregate has emerged: recycled concrete aggregate , which is produced by crushing concrete reclaimed from demolished highways, buildings and other structuresAggregates Lehigh Hanson, IncDec 02, 2020 The aggregate with particle size between 475 mm and 90mm is coarse aggregate, commonly known as the stone It can be divided into two types, that is, gravel and pebble Gravel is natural rock or rock by mechanical crushing, screening system, and the particle size is larger than 475 mm of rock particlesHow to Process Sandgravel Aggregate?

Quarrying Process And Quarry Products

The larger sized stones pass through to the final crushing stages where they are fed through a series of cone crushers and screens The output from the final cone crushers is conveyed to a screen house where large multiple deck screens sort the crushed stone into the required aggregate sizes