mobile units to extract gold from ore safloorcoza

mobile units to extract gold from ore cell phone recycling gold pacebutler recycling blog this article is all about explaining how lucrative cell phone recycling is, its impact on the conservation of mobile units to extract gold from ore Popular es Citigold Gold Extraction Citigold Corporation Citigold Corporation has access to a modern gold extraction plant that is located away from the populated areas of Charters Towers about 10 kilometres south west of the city centre along the Gregory Highway on the historically rich Black mobile units to extract gold from ore swidmetpl This will have the potential to open up the application of the technology to a greater range of ore types and will be scalable to larger projects The process concepts entail a mobile plant, vat leach for coarse material, tank leach with thickener/filter as parallel circuit to treat fines, “dry” tails stacking, and plugandplay modules Extracting gold without cyanide Chemical Engineering

extracting gold from sand Solution for ore mining

I adjust the engine so that the water flow is swift enough to wash out light sand and still save all of the black sand and gold gold, you can finish extracting How to extract Gold, Platinum, Rhodium from “Black Sand” ore How to extract Gold, Platinum, Rhodium from “Black Sand” ore concentrate? by on August 18, 2010Gold Extraction from Tailings Star Trace has been providing a standard technique for extracting the mineral contents from the mining tailings Star Trace will start the process by sample testing through the mineral content of the tailingsGold Extraction from Tailings and mine waste In goldrich ore deposits, there are concentrations of gold at one or two parts per million, says Dave Holwell, an economic geologist at the University of Leicester That equates to 1g or 2g per Who what why: How much gold can we get from mobile

Extracting Gold HowStuffWorks

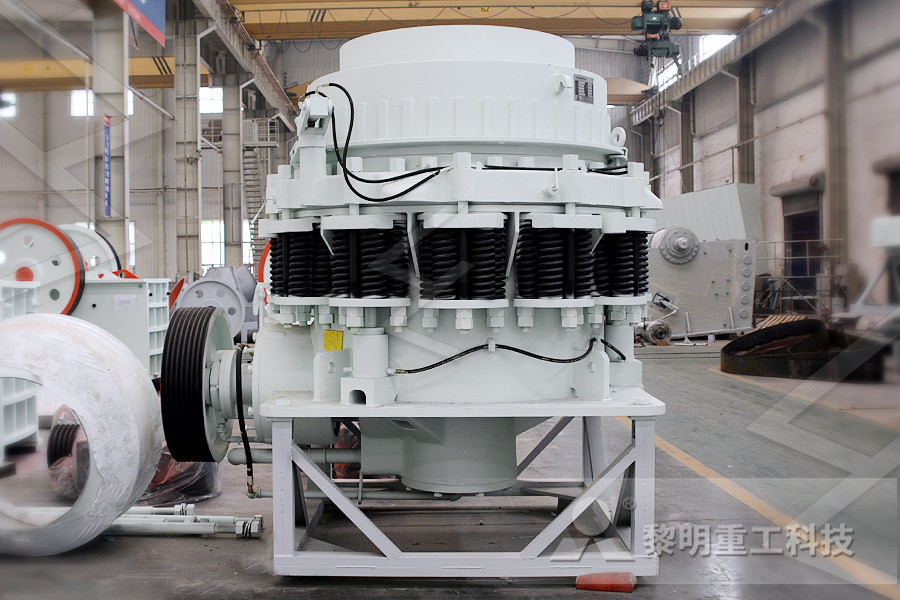

Removing the goldbearing rock from the ground is just the first step To isolate pure gold, mining companies use a complex extraction process The first step in this process is breaking down large chunks of rock into smaller pieces At a mill, large machines known as crushers reduce the ore Gold is an almost nonreactive metal, but halogens — chlorine, bromine, fluorine and iodine — can dissolve it Chlorine is the cheapest and lightest product that can achieve this Bleach is the chemical compound sodium hypochlorite When combined with hydrochloric acid, the mixture produces chlorine that dissolves gold from gold oreHow to Use Bleach on Gold Ore to Remove Gold Sciencing It is an extraction method used to extract the most reactive metals from an ore; a compound of a metal mixed with impurities It is the most expensive since a lot of electricity is used Electrolysis deals with the addition of electrons into the metal ions at a cathode terminal(the negative electrode)5 Different Types of Extraction (and Experiments

Gold extraction process

In goldrich ore deposits, there are concentrations of gold at one or two parts per million, That equates to 1g or 2g per tonne And the idea that 41 handsets contain 1g of gold stems from a UN report on electronic waste a tonne of old phones (weighed without their batteries) yields about 300g of gold Getting gold from gold ore requires the process referred to as “smelting” The ore is placed in an induction furnace crucible with a mixture of flux This flux is responsible for quick and easy removal from gold from its ore as well as removing impurities The induction gold smelting furnace is then fired up at 1149 degree celsiusGold Melting Furnace, CE Approved Gold Smelting extract trace amounts of gold from several complex water mixtures that include wastewater, fresh water, ocean water, and solutions used to leach gold from electronic waste and sewage sludge ash The material has an exceptional removal capacity, 934 mg gold/g of composite, and extracts gold from these complex mixtures at record, Selective Extraction of Trace Amounts of Gold from

GOLD diamond

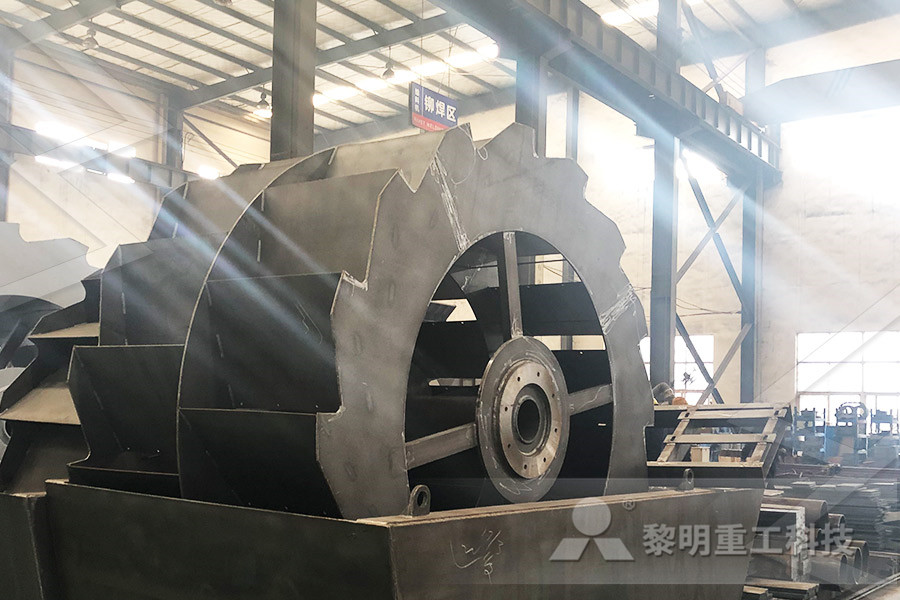

This technology allows you to extract gold in a continuous stream of ore from 40 milligrams with an accuracy of 95% In addition to such obvious advantages, when using the proposed equipment, there is a number of other positive points: The possibility of equipment delivery to hardtoreach locations;Crushed ore is piled onto large pads that are sprayed with chemicals The chemicals help break down and separate the precious metals from the waste material The process, known as heap leach stacking, requires a big operational area and depends on large volumes of material to extract Mobile mining WoodThe Central gold deposits are accessed by 'decline' (downward sloping tunnel) The size is usually 4 metres wide by 45 metres high This size allows access for all the mobile mining equipment that is used to extract the gold ore Mining method is modern drill and blast techniqueCitigold Gold Mine Operations Citigold Corporation

Sulfur radical species form gold deposits on Earth

gold; sulfur; ore deposit; hydrothermal fluid; trisulfur ion; The formation of gold deposits on Earth requires aqueous fluids that extract gold from minerals and magmas and transport and precipitate the metal as economic concentrations in ores that are three to six orders of magnitude larger than the Au mean content (∼0001 ppm) of common crustal and mantle rocks (1 The Future of EWaste and Gold Recycling The United States produces more ewaste than any other country in the world In 2012 alone, this country generated over 34 million tons of electronic wasteAn estimated 20 to 50 million tons are generated worldwide each year, which includes millions of laptops, smartphones, and mobile devicesHow Much Gold is in One Cell Phone? (And What’s it It does not guarantee the gold will be mined, or even that it can be mined, but it holds out the possibility The higher the grade of ore, the more gold present and the more costeffective it will be getting to it As in most businesses, costeffectiveness is the name of the game, and in mining, that means controlling how you run your mineHow Gold Mining Works Gold News BullionVault

Mobile phone waste management and recycling:

Kim et al (2011) selectively recovered gold from waste mobile phone PCBs using a hydrometallurgical process They could extract more than 95% gold with purity as high as 999% They found out that the leaching efficiency of gold increased with increase in In goldrich ore deposits, there are concentrations of gold at one or two parts per million, That equates to 1g or 2g per tonne And the idea that 41 handsets contain 1g of gold stems from a UN report on electronic waste a tonne of old phones (weighed without their batteries) yields about 300g of goldGold extraction processMobile, selfcontained and simple to set up All models are trailer mounted, fully mobile systems This allows for access to typically remote or inaccessible mining locations at minimal cost Setup is completed in minutes for smaller units or hours for large units vs days or even months for other systemsFeatures and Benefits of our gold recovery systems

, Selective Extraction of Trace Amounts of Gold from

, Selective Extraction of Trace Amounts of Gold from Complex Water Mixtures with a Metal−Organic Framework (MOF)/Polymer Composite Daniel T Sun,† Natalia Gasilova,† Shuliang Yang,† Emad Oveisi,‡ and Wendy L Queen*,† †Institute of Chemical Sciences and Engineering, École Polytechnique Féde ́rale de Lausanne (EPFL), CH1950 Sion, Switzerland value, gold and the other precious metals dominate, as shown in the lower part of the table For PC boards, cell phones and the calculator, gold and the Volume counts – content of gold and other metals in mobile phones and computers in relation to total demand from these appliances and world mine production Figure 1 1300 Million unitsRecycling of gold from electronics: Costeffective use The Future of EWaste and Gold Recycling The United States produces more ewaste than any other country in the world In 2012 alone, this country generated over 34 million tons of electronic wasteAn estimated 20 to 50 million tons are generated worldwide each year, which includes millions of laptops, smartphones, and mobile devicesHow Much Gold is in One Cell Phone? (And What’s it Worth?)

Mobile phone waste management and recycling: Views and

Kim et al (2011) selectively recovered gold from waste mobile phone PCBs using a hydrometallurgical process They could extract more than 95% gold with purity as high as 999% They found out that the leaching efficiency of gold increased with increase in It takes 100 tons of gold ore to get 10 ounces of the precious metal, said Privahini Bradoo, CEO of BlueOak Resources, a Californiabased startup that launched a large “urban mining” facility in AReusing and Recycling: Big Challenges, Big Opportunities Supercritical CO 2 is simply the best way to extract essential oils on an industrial scale CO 2 is highly efficient, often able to extract > 95% of precious compounds and oils In addition, supercritical CO 2 has a number of other advantages: CO 2 costs far less than ethanol – only pennies per pound in bulk; CO 2 leaves no residual solvents – no risk of product contaminationApplied Extracts – Supercritical CO2 Extraction Systems

How Gold Mining Works Gold News BullionVault

It does not guarantee the gold will be mined, or even that it can be mined, but it holds out the possibility The higher the grade of ore, the more gold present and the more costeffective it will be getting to it As in most businesses, costeffectiveness is the name of the game, and in mining, that means controlling how you run your mine2 天前 Insitu leaching has been successfully used to extract uranium from permeable sandstones in Texas, Wyoming, and Nebraska, and insitu leaching of copper has been successfully demonstrated in underground copper mines in Arizona, where prior mining has created sufficient permeability for leaching solutions (lixiviants) to contact ore minerals 3 Technologies in Exploration, Mining, and Processing