jaw crusher bearings, jaw crusher bearings Suppliers

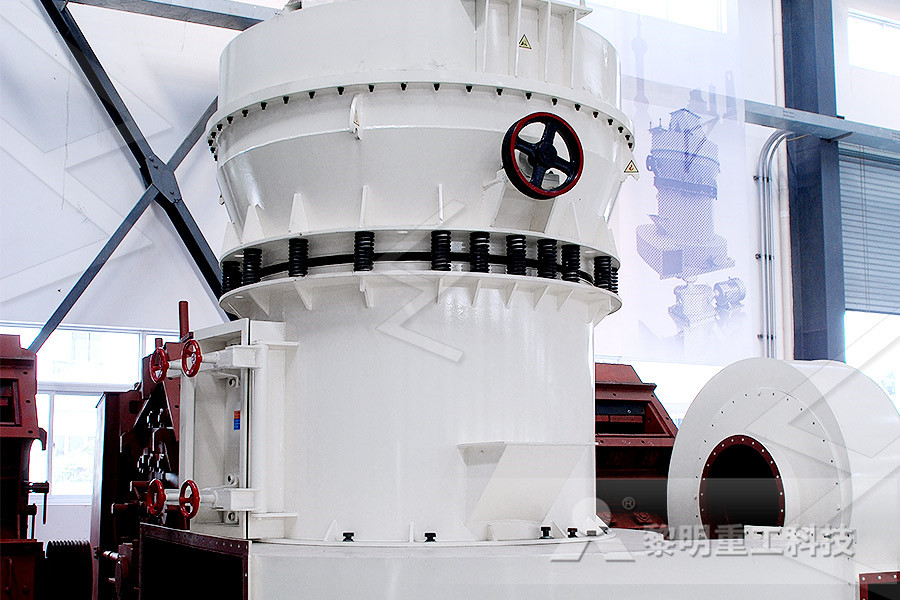

A wide variety of jaw crusher bearings options are available to you, There are 2,049 suppliers who sells jaw crusher bearings on Alibaba, mainly located in Asia The top countries of suppliers are China, Hong Kong SAR, and Thailand, from which the percentage of jaw crusher bearings supply is 98%, 1%, and 1% respectively Bearings In Jaw Crusher Bearing plays important role in the modern mechanical equipment Bearing is a component that fixes and reduces the load friction coefficient in the transmission process of machinery In other words, bearing is used to reduce the friction coefficient in the power transmission process and keep the axis stay in the centerBearings In Jaw CrusherComparing with traditional jaw crusher, it has larger capacity and crushing ratio, bigger range of input size, evener product size, and easier3 Bearing seat is designed integrally, so manufacturing difficulty is greatly reduced, and bearing life is increased 4 here is a thick replaceable plate on the topBearing In Jaw Crusher

Jaw Crusher an overview ScienceDirect Topics

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation The capacity is primarily a function of: 1 crusher design characteristics such as width and depth of the crushing chamber,Jaw Crusher Bearing Design,Jaw Crusher Bearing Lubrication Jaw crusher bearing design in liming is professional Jaw crusher bearing lubrication is very important in the jaw crusher bearing system KNG5899Crush Flyerqxd:KNG5899Crush FlyerCrusher Bearing Crusher Mills, Cone Crusher, Jaw Jaw crushers are designed to impart an impact on a rock particle placed between a fixed and a moving plate (jaw) The faces of the plates are made of hardened steel Both plates could be flat or the fixed plate flat and the moving plate convex The surfaces of both plates could be plain or corrugatedJaw Crusher ScienceDirect

Jaw Crusher Components Parts 911 Metallurgist

Although the jaws do the work, the real heart of the jaw crusher and its components are the toggle plates, the pitman, and the ply wheel These are the parts and components that generate the crushing action and provide the energy needed to The type of crushed materials determines how to design the max amplitude of swing of the jaw and the amplitude adjusted by changing the eccentric The length from 1 to 7 cm depends on the crusher machine size Jaw crushers Jaw Crusher Primary Crusher in Mining Aggregate housings (open design) are available for locating bearings (design BF) and for floating bearings (design BL) The split housings of series MGO were especially developed for mill applications They are designed for oil lubrication and feature particularly effective seals Machining tolerances For mounting with sleeves, the shaft seats are machinedThe Design of Rolling Bearing Mountings Schaeffler

Bearings In Jaw Crusher

Bearings In Jaw Crusher Bearing plays important role in the modern mechanical equipment Bearing is a component that fixes and reduces the load friction coefficient in the transmission process of machinery In other words, bearing is used to reduce the friction coefficient in the power transmission process and keep the axis stay in the centerJaw Crusher For Reference Price: Get Latest Price Jaw crusher is the vital equipment in crushing industry Processing capacity: 12200t/h Feeding size: 1251200mm Appliable Materials: Limestone, granite, pebbles, cobble, iron ore, basalt and all kinds of hard and soft ores with compressive strength not higher than 320 Mpabearings for jaw crusher Bussa Machinery Forced Feed Jaw Crusher Type #2 Design Small Jaw Crusher for Sale This type of crusher is similar in design to the Type I listed above except for having a frame and bumper made of cast steel This steel construction makes the unit lighter per unit of size, and adds considerable strengthSmall Jaw Crushers 911 Metallurgist

Jaw Crusher Sanme

Jaw crusher is commonly known as jaw breaking, also known as tiger mouth A crushing chamber is composed of two jaw plates, a movable jaw and a static jaw, which simulates the movement of the two jaws of the animal to complete the crushing operation of the material Jaw crusher parts that contain frame, movable and stationary plate, bearing, eccentric shaft, toggle jaw, flywheel, eccentric shaft, belt pulley, backmoving spring, jaw plate crusher parts Solid and durable property JXSC the crushers machine with a nonwelded frame has been proved that it has outstanding solid and durable strength All the Jaw Crusher Primary Crusher in Mining Aggregate DESIGN AND OPERATIONS CHALLENGES OF A SINGLE TOGGLE JAW CRUSHER: A REVIEW C Okechukwu, et al Nigerian Journal of Technology Vol 36, No 3, July 2017 817 attached to it It has been demonstrated by Sutti and Jonkka [19] that a pitman with a crosssectional supportDESIGN AND OPERATIONS CHALLENGES OF A SINGLE

Grizzly King Jaw Crusher Sepro Aggregate Systems

The highest durability and longevity of any jaw crusher on the market The Grizzly King Jaw Crusher is heavier and stronger than most jaw crushers on the market Lighter crushers sometimes have flexing in the frame which can lead to cracking – this rarely happens with the Grizzly King Jaw Crusher’s reinforced design Big reinforcing ribs provide frame rigidity and add to the weight of In severe cases, the jaw crusher will be damaged directly, and even worse, machine explosion is possible So we need to do preparation work well, especially in summer There are several reasons that can cause high temperature of small jaw crusher bearing: bearing wear or damageBeware of Jaw Crusher Bearings in High Summer The Design of Rolling Bearing Mountings PDF 6/8: Construction machinery Raw material processing Steel mill and rolling mill equipment Bearing mounting of a doubletoggle jaw crusher Locating bearing Floating bearing Swing jaw Eccentric shaft Pitman 93 Hammer mill Hammer mills are mainly used for crushing ores, coal, and stoneThe Design of Rolling Bearing Mountings Schaeffler

75450kw 501500tons/Hour HighPerformance

Jaw Crusher Manufacturer, Jaw Crusher Price, Heavy Duty Jaw Crushing Machine manufacturer / supplier in China, offering 75450kw 501500tons/Hour HighPerformance Mining Jaw Crusher Machine, Pn1, 25MPa DN32800mm Environmental HighDensity Polyethylene Water Supply Pipe/HDPE Pipe/Buried Pipe/Water Pipe for Building Water Delivery System, Pn1, 25MPa DN32800mm Bearings In Jaw Crusher Bearing plays important role in the modern mechanical equipment Bearing is a component that fixes and reduces the load friction coefficient in the transmission process of machinery In other words, bearing is used to reduce the friction coefficient in the power transmission process and keep the axis stay in the centerBearings In Jaw Crusher Singletoggle jaw crushers – design and operating principle Technical data Singletoggle jaw crusher Design Singletoggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plateIndustrial Solutions Jaw crushers ThyssenKrupp

SKJ Series Jaw CrusherShunky Machinery

SKJ Series Jaw Crusher SKJ series European Jaw Crusher is generally suitable for primary and secondary crushing Adopting the most advanced technology and craftsmanship in the world, SKJ series European Jaw Crusher is the top choice when crushing hard, strongcorrosive materials effectively with unique advantages on structural design, working performance, service life and maintenance The front end frame and swing jaw holder are protected from wear and damage at the inlet and discharge ends, due to the overlapping design of the jaw dies Replaceable backing plates protect the jaw die seating areas on the front end frame and swing jaw holder At the top of the jawholder, a guard protects the bearing housingJaw Crushers JW Series The highest durability and longevity of any jaw crusher on the market The Grizzly King Jaw Crusher is heavier and stronger than most jaw crushers on the market Lighter crushers sometimes have flexing in the frame which can lead to cracking – this rarely happens with the Grizzly King Jaw Crusher’s reinforced design Big reinforcing ribs provide frame rigidity and add to the weight of Grizzly King Jaw Crusher Sepro Aggregate Systems

RHINO series Primary Jaw Crusher CPC Crushing and

The Primary Jaw Crusher is a vital piece of machinery Often the success (or failure) of a Crushing Plant depends upon its performance The Primary Crusher receives large lumps of rock directly from mines, and reduces it to sizes suitable for downstream operations CPC 3624 Rhino Primary Jaw Crusher – Upto 150 TPH Capacity In severe cases, the jaw crusher will be damaged directly, and even worse, machine explosion is possible So we need to do preparation work well, especially in summer There are several reasons that can cause high temperature of small jaw crusher bearing: bearing wear or damageBeware of Jaw Crusher Bearings in High Summer Temperature CHIPMUNK JAW CRUSHER TYPE VD the following directions for operation and maintenance be carefully observed MECHANICS OF ITS SUCCESFUL DESIGN The upper end of the jaw travels in a circular path driven by the eccentric shaft The lower end VD67 Bearing Casting with Caps Bushings 23/11 VD68R Right Hand Bearing Cap 3/1 BICO INC CHIPMUNK JAW CRUSHER TYPE VD

The Design of Rolling Bearing Mountings Schaeffler

The Design of Rolling Bearing Mountings PDF 6/8: Construction machinery Raw material processing Steel mill and rolling mill equipment Bearing mounting of a doubletoggle jaw crusher Locating bearing Floating bearing Swing jaw Eccentric shaft Pitman 93 Hammer mill Hammer mills are mainly used for crushing ores, coal, and stone Typical applications for our singletoggle jaw crushers are in mining, quarrying and recycling The jaw crushers handle ores, rock, gravel and recycled concrete Proven design with a long history of trouble free operation in tough mining and quarrying applications; Frame fabricated from low carbon steel, reinforced with ribs throughoutST60 Jaw Crusher