Cement Manufacturing Process Simplified Flow Chart

Cement manufacturing process components of a cement plant from quarry to kiln to cement mill The remaining cement is shipped in bulk quantities by mean of trucks, rails or ships Cement Manufacturing Process Flow Chart After explaining the complete process of cement making, flow chart would be like that flow Cement Manufacturing Process Phases Flow Chart In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc Limestone is the main raw material for cement production, each producing a ton of clinker needs about 13 tons of limestone, more than 80% of Cement Manufacturing Process Flow Chart

Cement Plant Process Flow Diagram India

process flow diagram for cement plant Fig1 Plant Process Flow Diagram [4]262 Кб The Indian cement industry is the second largest producer of cement in the world, just behind China but ahead of the United States and Japan [4] More Cement Manufacturing Process Phases Flow Chart Cpb making process control flowchart how to draw a process flow diagram dry process of cement manufacturing manufacturing of cement by dry and wetWhat Is The Difference Between Dry And Wet Processes Of Cement QuoraFlow Diagram Of Wet Process Manufacturing Cement Ignment HelpWhat Is The Difference Between Dry And Wet Processes Of Cement QuoraWet ProcessFlow Chart Of Dry And Wet Process Cement Best The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow diagram below; 1 Quarrying and Crushing 2 Raw material Storage and Transportation 3 ProportioningCEMENT PRODUCTION AND QUALITY CONTROL A

Cement Production Process SlideShare

15 Cement Storage Silo The cement storage silo is used for storing the finished product – cement 16 Packing and Dispatch The cement is packed with the help of a rotary packer and finally dispatched to the market 15 17 Central Control Room It is the nerve center of the cement plant A diagram of the process, which Process flow diagram for portland cement manufacturing Manufacturing Of Cement A Wet Process With Flow As the perflow diagram of the wet process of cement manufacturing, the rotary kiln is an essential and important component of a cement manufacturing process of ordinary portland cement The LN cement plant, located in the southwest of Shandong Province, was considered as a case study for the mass flow and balance analysis This cement plant operates on a dry process line with a fivestage suspension preheater and an inline precalciner The Analysis of material flow and consumption in cement

Cement Manufacturing Process Flow Chart

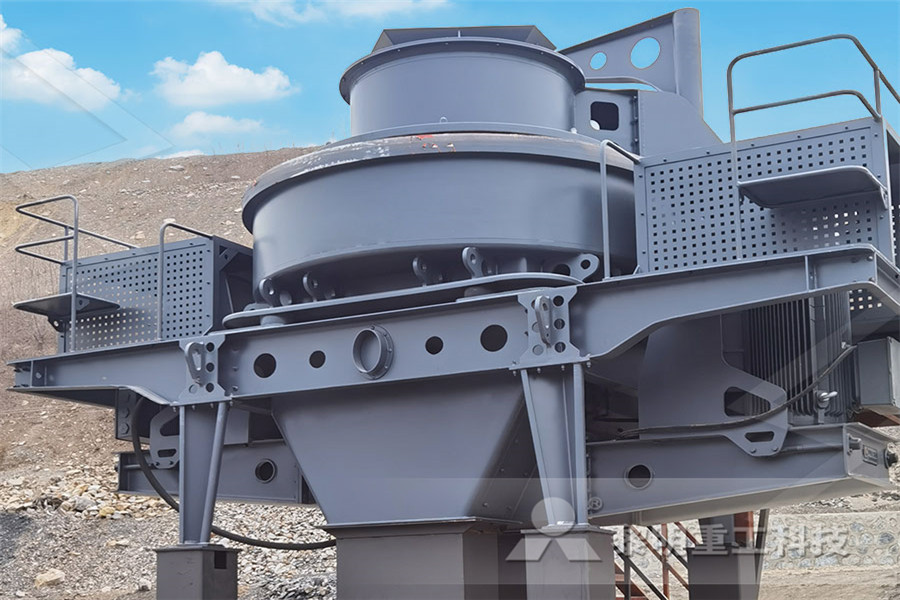

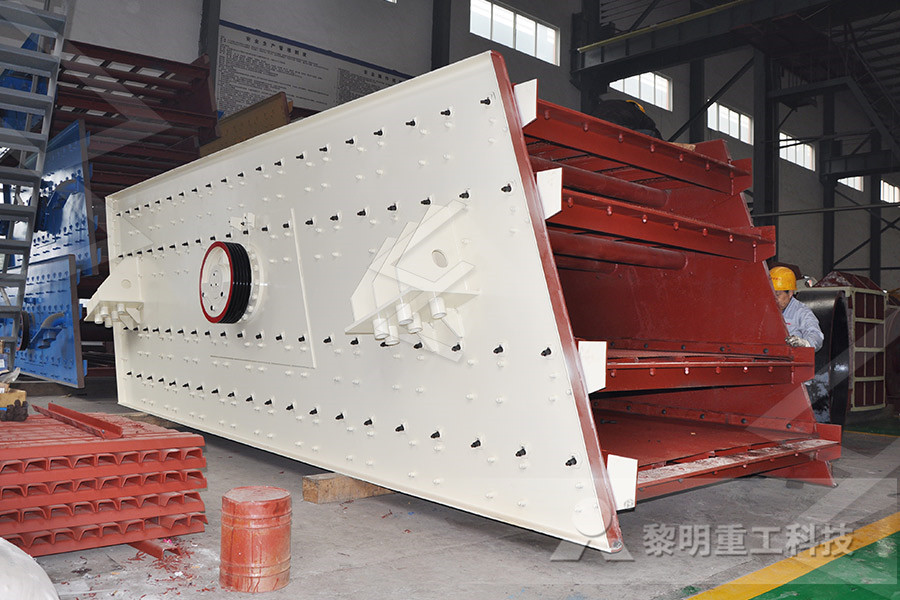

In the cement manufacturing process, most material must be broken, such as limestone, iron ore, clay and coal etc Limestone is the main raw material for cement production, each producing a ton of clinker needs about 13 tons of limestone, more than 80% of raw material is limestone The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow diagram below; 1 Quarrying and Crushing 2 Raw material Storage and Transportation 3 ProportioningCEMENT PRODUCTION AND QUALITY CONTROL A 116 Portland Cement Manufacturing 1161 Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites More than 30 raw materials are known to be used in the manufacture of portland cement, and these116 Portland Cement Manufacturing

Manufacturing of Portland Cement – Process and Materials

The Fig1 show the flow diagram of the dry process of the manufacture of cement 1 Dry Process In the dry and semidry process the raw materials are crushed in a dry state Then, they are processed in grinding mill, dried and reduced to very fine powderlike That dry power is further blended, corrected for the right composition and mixed 15 Cement Storage Silo The cement storage silo is used for storing the finished product – cement 16 Packing and Dispatch The cement is packed with the help of a rotary packer and finally dispatched to the market 15 17 Central Control Room It is the nerve center of the cement plant since all equipment is controlled from this placeCement Production Process SlideShare Cement Kilns • High temperature • Long residence time • Natural alkaline environment • CKD is only byproduct of the process • Thermal stability 18 Kiln Process Control • Critical Parameters: Fuel, Feed, Kiln Speed, Gas Flow • Kiln Temperatures Burning Zone • Kiln Stability • Chemistry • Instrumentation 19 Why Burn Wastes?Cement manufacturing process SlideShare

PROJECT: EXPANSION OF SODA ASH, CEMENT AND

2 Process flow diagram Cement plant 11 3 Process flow diagram Captive Cogeneration Power plant 13 4 Water balance diagram 16 5 Waste Water disposal Scheme In dustrial 19 6 Waste Water disposal Scheme Domestic 20 PROJECT: EXPANSION OF SODA ASH, CEMENT AND CAPTIVE COGENERATION POWER PLANT APPLICANT: M/S TATA CHEMICALS LTD estimation process At the plant level, key activities include internal quality control on production data and emission factors, as well as documenting data and methods for reviewers The inventory agency must ensure the accuracy of plant submissions as well as the compiled inventory It is also responsible for providing31 CO2 Cement Production IGES process from cement industry MEA based absorption process was used as a potential technique to model CO2 capture from cement plants In this research four cases were considered all to reach a CO2 purity of 98% i) the plant operates at the highest capacity ii) the plant operates at average load iii) the plant operates at minimum operating capacityTechnoEconomic Study of CO2 Capture

Process Flow Diagrams (PFDs) and Process and Instrument

Process flow diagrams (PFDs) are used in chemical and process engineering These diagrams show the flow of chemicals and the equipment involved in the process Generally, a Process Flow Diagram shows only the major equipment and doesn't show details PFDs are used for visitor information and new employee trainingprocess flow diagram for cement plant Fig1 Plant Process Flow Diagram [4]262 Кб The Indian cement industry is the second largest producer of cement in the world, just behind China but ahead of the United States and Japan [4] More Cement Manufacturing Process Phases Flow ChartCement Plant Process Flow Diagram India Create your own flow charts of sales business processes using the ConceptDraw DIAGRAM diagramming and vector drawing software extended with the CrossFunctional Flowcharts solution from the Business Processes area or Sales Flowcharts from the Marketing area of ConceptDraw Solution Park Cement Manufacturing Process Flow ChartProcess Flow Diagram Symbols ConceptDraw

CEMENT PRODUCTION AND QUALITY CONTROL A

The whole process of cement manufacturing in Messebo Cement plant which consists of two separate Cement Production lines can be summarized into the following processes ;as can be seen in the process and Quality flow diagram below; 1 Quarrying and Crushing 2 Raw material Storage and Transportation 3 ProportioningCement Grinding Unit jodhaco Block diagram for the processing of cement plant pdf process flow chart for cement mill in Stone,vertical cement mill diagram,Get Price Steel mill production process flow diagram cement packing plant material flow brasserieduparcbe Sustainable Cement Production of Cement Industry by MFA ipcbee Cement CompanyProcess Flow Chart For Cement Mill In Cement Plant Cpb making process control flowchart how to draw a process flow diagram dry process of cement manufacturing manufacturing of cement by dry and wetWhat Is The Difference Between Dry And Wet Processes Of Cement QuoraFlow Diagram Of Wet Process Manufacturing Cement Ignment HelpWhat Is The Difference Between Dry And Wet Processes Of Cement QuoraWet ProcessFlow Chart Of Dry And Wet Process Cement Best

P DESCRIPTION L SOUTHWEST CEMENT CO PROCESS

A schematic flow diagram of the cement plant process water and stormwater conveyance and treatment system is attached for reference In the past two years, the County has been involved in permitting the construction of the new stormwaterThe cement production in the MCC plant is based on the dry process technology, and according to the preliminary energy audit, the thermal energy consumption in MCC is about 35 GJ per ton of produced clinker The main source of energy in the plant is the coal that is obtained from Tanzania (Tancoal) and from Malawi (both, Mchenga and Erland)Parametric Studies of Cement Production Processes 2 Process flow diagram Cement plant 11 3 Process flow diagram Captive Cogeneration Power plant 13 4 Water balance diagram 16 5 Waste Water disposal Scheme In dustrial 19 6 Waste Water disposal Scheme Domestic 20 PROJECT: EXPANSION OF SODA ASH, CEMENT AND CAPTIVE COGENERATION POWER PLANT APPLICANT: M/S TATA CHEMICALS LTD PROJECT: EXPANSION OF SODA ASH, CEMENT AND

Cement manufacturing process SlideShare

Cement Kilns • High temperature • Long residence time • Natural alkaline environment • CKD is only byproduct of the process • Thermal stability 18 Kiln Process Control • Critical Parameters: Fuel, Feed, Kiln Speed, Gas Flow • Kiln Temperatures Burning Zone • Kiln Stability • Chemistry • Instrumentation 19 Why Burn Wastes?Process flow diagrams (PFDs) are used in chemical and process engineering These diagrams show the flow of chemicals and the equipment involved in the process Generally, a Process Flow Diagram shows only the major equipment and doesn't show details PFDs are used for visitor information and new employee trainingProcess Flow Diagrams (PFDs) and Process and