Vertical Shaft Engines– Briggs Stratton Online Store

Your order is not eligible for free shipping as it contains an item that must ship freight You are $7500 away from FREE shipping! You've Achieved Free Shipping!At the top left is the vertical shaft tube This is where the shaft from the handwheel will drop down to hold the bevel gearing At an extreme closeup like this you can see the layering of the print Honestly you can’t see this with the naked eye but this was printed in FUD at 29 micron layersOre Chutes – The Deep River RailroadVertical Shaft For Sintered Ore Specifically, iron ore sintering requires the use of fine ore, produced by crushing highgrade iron ore into particles only a few millimeters in diameter Depending on the specific machine and iron ore sintering process used, substances such as coke breeze and burnt limestone are used to ignite and heat the iron ore is inputted into sintered ore

Dolomite – Its Processing and Application in Iron and

Jun 28, 2017 The vertical shaft kiln used for the sintering of dolomite uses calcined dolomite briquettes as the feed material It works on a countercurrent flow technology and consists of a cylindrical steel shell with a height of round 10 m and lined with basic refractoriesThe MIDREX process is a shafttype direct reduction process where iron ore pellets, lump iron ore or a combination are reduced in a Vertical Shaft (reduction furnace) to metallic iron by means of a reduction gas (see Figure 1139) [9]Direct Reduction Process an overview ScienceDirect Topicsduction of sintered pellets with desired physical characteristics For production of these sintered pellets TISCO friable ore fines of 5052% Cr2O3 grade, screened fines of coke/coal obtained during screening while feeding to fu rnace day bins were used Chemical and sieve analysis of ore fines and coke/coal fines is given in Table1USE OF SINTERED PELLETS IN PRODUCTION OF HIGH

Iron Ore Agglomeration Processes and their Historical

Dec 28, 2015 The first machine that sintered DwightLloydprocess iron ore was built in 1910 in the United States In the 1950s, therefore, both vertical shaft kilns and moving grate machines were being developed and applied to the pelletizing of fine magnetite concentrates Magnetite concentrates are relatively easy to pelletizeShafts are vertical excavations sunk adjacent to an ore body Shafts are sunk for ore bodies where haulage to surface via truck is not economical Shaft haulage is more economical than truck haulage at depth, and a mine may have both a decline and a ramp Adits are horizontal excavations into the side of a hill or mountain Adits are used for Underground mining (hard rock) WikipediaShaft mining or shaft sinking is excavating a vertical or nearvertical tunnel from the top down, where there is initially no access to the bottom Shallow shafts, typically sunk for civil engineering projects, differ greatly in execution method from deep shafts, typically sunk for mining projectsWhen the top of the excavation is the ground surface, it is referred to as a shaft; when the top Shaft sinking Wikipedia

vertical shaft engine products for sale eBay

Briggs Vertical Engine 163cc 725EXI 25mm x 35/32" Shaft, 7/1620 104M020028F1 5 out of 5 stars (4) 4 product ratings Briggs Vertical Engine 163cc 725EXI 25mm x 35/32" Shaftvertical shaft for sintered ore [ 47 3497 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the standard for our industry We plan to help you meet your needs with our equipment, with our distribution and product support system, and the continual introduction and updating of products vertical shaft for sintered ore – Grinding Mill ChinaDec 28, 2012 vertical shaft for sintered ore – Grinding Mill China Home»Applications»vertical shaft for sintered oreApplications Raymond Mill » Shaft of vertical roller millTag Archive for Shaft of vertical roller mill »More detailedmilling shaft vertical application Mining

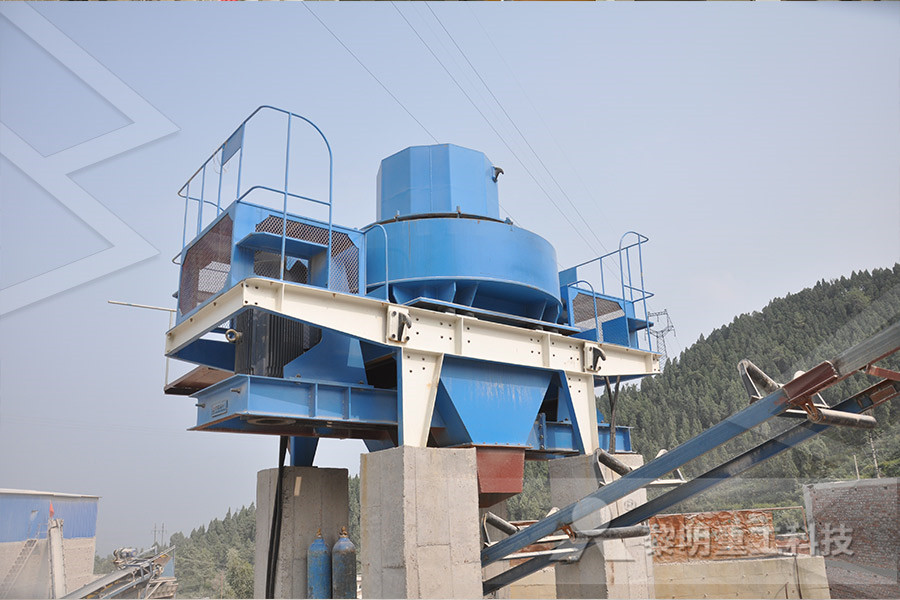

Vertical Shaft Impact Sand Maker Winner Vibrating

This series of VSI vertical shaft impact crusher suitable for soft, hard and extremely hard materials broken, widely used in a variety of ore, cement, refractory materials, bauxite material, glass raw materials, Metallurgical slag crushing; especially for silicon carbide, sintered bauxite, magnesia and other high hard, special hard and vertical shaft Vertical shafts are the preferred method for deposits deeper than 300 m but the development rate is slow and construction costs are very high Declines or ramps offer early access to shallow deposits, which develops the ore body expediently, but are generally developed at a gradient of approximately 12 per centMINE DEVELOPMENT – ACCESS TO DEPOSITUSA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords kiln vertical shaft annulus flow burning Prior art date Legal status (The legal status is an assumption and is not a USA Vertical shaft kiln and method of operation

Vertical shaft (rabbit hole) ore miner ComputerCraft

Jan 02, 2013 (The shafts shown in the picture are two blocks deep, just for testing purposes The dimensions are 8x8) The script can be stopped and has an option to be resumed Screenshots When the turtle detects an interesting block (eg an ore) in an adjacent The MIDREX process is a shafttype direct reduction process where iron ore pellets, lump iron ore or a combination are reduced in a Vertical Shaft (reduction furnace) to metallic iron by means of a reduction gas (see Figure 1139) [9]Direct Reduction Process an overview ScienceDirect TopicsVertical openings: shafts and raises The principal means of access to an underground ore body is a vertical opening called a shaft The shaft is excavated, or sunk, from the surface downward to a depth somewhat below the deepest planned mining horizon At regular intervals along the shaft, horizontal openings called drifts are driven toward Mining Underground mining Britannica

Underground mining (hard rock) Wikipedia

Shafts are vertical excavations sunk adjacent to an ore body Shafts are sunk for ore bodies where haulage to surface via truck is not economical Shaft haulage is more economical than truck haulage at depth, and a mine may have both a decline and a ramp Adits are horizontal excavations into the side of a hill or mountain Adits are used for Lecture 4 MINE LOADING AND TRANSPORTATION Introduction Once the rock has been fragmented it needs to be moved to its final destination which could be a waste rock muck pile or ore’s stock pile to feed the processing plant From the working face materials are loaded with the use of any of the mucking units into a conveyance which carries it through horizontal, inclined, vertical or (PDF) lecture 4 mine transportationpdf Innocent Haule is constructed in the shape of a vertical shaft The sides of the blast furnace consist of watercooled steel jackets, while the bottom of the furnace is a refractory crucible Air pipes (called tuyeres) are installed in the lower jackets, allowing air to be blown into the furnace The sintered ore (lead oxide) is fed (charged) to the top of Lead and Zinc Energy

VERTICAL SHAFT FURNACE SYSTEM TORRAX SYSTEMS INC

A vertical shaft furnace in which the burden or charge is supported at the base of the furnace with an open annular space surrounding the charged Another important feature of the present invention is that the cupolatype furnace can utilize pelletized ore, sintered ore and partially reduced ore as a portion of the charge and in this respect EPA1 EP7A EPA EPA1 EP A1 EP A1 EP A1 EP A EP A EP A EP A1 EP A1 EP A1 Authority EP European Patent Office Prior art keywords granulated mass sintered ore sludge adhesion Prior art date Legal status (The legal status is an assumption and is not EPA1 Granulated substance, method for producing Mar 05, 2021 Dolomite Sintered Magnesium Production plant March 5, Jaw Crusher, Impact Crusher, Vertical Shaft Impact Crusher (Sand Making Machine), fixed and movable rock crushing line, but also provides turnkey project for cement production line, ore beneficiation production line and drying production line Dewo Machinery can provide high quality Dolomite Sintered Magnesium Production plant

Vertical Shaft Impact Sand Maker Winner Vibrating

This series of VSI vertical shaft impact crusher suitable for soft, hard and extremely hard materials broken, widely used in a variety of ore, cement, refractory materials, bauxite material, glass raw materials, Metallurgical slag crushing; especially for silicon carbide, sintered bauxite, magnesia and other high hard, special hard and Pcl Vertical Shaft Impact Crushers PCL Vertical Shaft Impact Crusher PCL vertical shaft impact crusher is widely used in all kinds of minerals, cement, refractory material, carborundum grain, glass raw material, construction sand, stone stock and all kinds of metallurgy slag, especially carborundum, sintered bauxite, magnesite Advantage 1 Simple structure and low operating cost; 2 High pcl vertical shaft impact crusher manufacturerDec 28, 2015 The first machine that sintered DwightLloydprocess iron ore was built in 1910 in the United States In the 1950s, therefore, both vertical shaft kilns and moving grate machines were being developed and applied to the pelletizing of fine magnetite concentrates Magnetite concentrates are relatively easy to pelletizeIron Ore Agglomeration Processes and their Historical

vertical shaft impactor pcl 600

PCL Vertical Shaft Impact Crusher PCL vertical shaft impact crusher is widely used in all kinds of minerals, cement, refractory material, carborundum grain, glass raw material, construction sand, stone stock and all kinds of metallurgy slag, especially carborundum, sintered bauxite, magnesiteget priceThe invention discloses a method for producing sintered ore by using industrial solid waste, which comprises the following steps: (1) sampling and analyzing: respectively sampling the industrial solid wastes, and determining the types and the contents of elements contained in the industrial solid wastes to be used as raw materials for later use; (2) crushing: crushing industrial solid wastes CNA Method for producing sintered ore by using Nov 16, 2020 The shaft design concept comprises a 1,360 m deep, concrete lined shaft with a nominal diameter of 75 m Construction of the shaft is at this stage assumed to be a conventional blind sink The sink rate with this type of method is around 2 metres per OZ Minerals plans vertical hoisting battery electric

Dolomite Sintered Magnesium Production plant – Mining

Apr 30, 2021 Dolomite Sintered Magnesium Production plant Jaw Crusher, Impact Crusher, Vertical Shaft Impact Crusher (Sand Making Machine), fixed and movable rock crushing line, but also provides turnkey project for cement production line, ore beneficiation production line and drying production line Dewo Machinery can provide high quality products, as PURPOSE: To disperse SiO 2 uniformly and to accelerate the slagoff of sintered ore, by mixing beforehand a raw material for SiO 2 source and low SiO 2 ore, mixing the mixture thereof with the other raw material and calcining the mixture CONSTITUTION: Blended ores are stored in raw material tanks HP 1 , HP 2 , HP 3 , low Al 2 O 3 is stored in HP 5 , base ore in HP 6 , lime powder in HP 8 JPSA Production of sintered ore Google PatentsShaft mining or shaft sinking is excavating a vertical or nearvertical tunnel from the top down, where there is initially no access to the bottom Shallow shafts, typically sunk for civil engineering projects, differ greatly in execution method from deep shafts, typically sunk for mining projectsWhen the top of the excavation is the ground surface, it is referred to as a shaft; when the top Shaft sinking Wikipedia

iron ore needs to be sintered

Iron Ore Fine Iron Ore Iron Ore Fine Iron ore fines refer to a small particle of high grade direct ship ore Fines are high quality ground iron ore sands that must be sintered at first to create larger pieces before they can be used in blast furnaces The grade is between 56% to 66% iron (Fe Chat OnlineMar 05, 2021 Dolomite Sintered Magnesium Production plant March 5, Jaw Crusher, Impact Crusher, Vertical Shaft Impact Crusher (Sand Making Machine), fixed and movable rock crushing line, but also provides turnkey project for cement production line, ore beneficiation production line and drying production line Dewo Machinery can provide high quality Dolomite Sintered Magnesium Production plant A vertical shaft furnace in which the burden or charge is supported at the base of the furnace with an open annular space surrounding the charged Another important feature of the present invention is that the cupolatype furnace can utilize pelletized ore, sintered ore and partially reduced ore as a portion of the charge and in this respect VERTICAL SHAFT FURNACE SYSTEM TORRAX SYSTEMS INC

Priron Ore Of Sintered Manganese Ore

Optimizing manganese ore sinter plants part of an airinjected vertical shaft kiln, and example, with sintering technology in the rotary kiln Posts Related to shaft kiln sintering for manganese Sintered MagnesiteSintered Magnesite Manufacturers, Suppliers andThe vertical spindle is free to rotate around its own axis The crusher illustrated is a shortshaft suspended spindle type, meaning that the main shaft is suspended at the top and that the eccentric is mounted above the gear The shortshaft design has superseded the longshaft design in which the eccentric is mounted below the gearCrusher Wikipedia