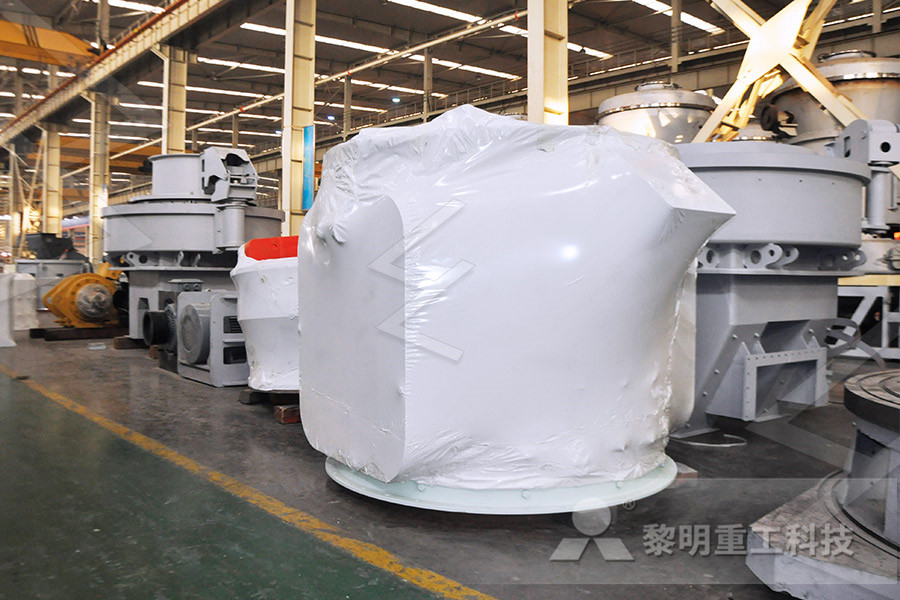

cone crusher bowl liner, cone crusher bowl liner

The hp 500 bowl liner and mantle cone crusher is the improved type of spring cone crusher and can be used to replace ordinary hydraulic cone crusher in the field of mining and construction mdash;mdash;all parts of hp 500 bowl liner and mantle cone crusher can be assembled, disassembled and repaired from the top and side part, including the bowl liner std coarse 3ft Bowl Liner Std Medium,, 3ft, 4ft, 4 1/4 ft, 5 1/2 ft, (bowl liner) and mantle are the main wear spare parts of cone,, Get Price liner crusher head Geo Genesisbowl liner std coarse 3ft bruisendgeelbe Optional Bowl Adjustment Package The Sentinel Advanced Hydraulic System also offers a Bowl Adjustment option that allows quick changes to the closed side setting (CSS), and also simplifies the process of turning the Bowl for liner changes Sentinel Advanced Hydraulic System (Currently for Symons® crushers from 41/4 Ft through 7Ft):Sentinel Advanced Hydraulic System

Excel Premium Components 911 Metallurgist

2 ft • 7ft Standard Shorthead Hydraulic Locking Post Duckworth Lock Post Feed Hopper Bowl Bowl Liner Feed Cone UBolt Assembly Torch Ring Mainshaft Sleeve Adjustment Ring Spring Bolt Spring Mainframe Seat Liners Mainframe Liner Arm Guard Mainframe Gear Counterweight Eccentric Inner Eccentric Bushing Outer Eccentric Bushing Step Plates Cone Crusher Liners Key words: Mantle, Bowl Liner, Concave Permanscess has been providing premium manganese steel and hight chrome crusher liners for decades our liners have been proven in mining and aggregate production to achieve and often exceed the performance of the equivalent castings supplied by Original Equipment Manufactures Our products are available from 13% to 21% in CONE CRUSHER LINER permanscess21 Bowl liner 22 Hydraulic adjustment motor 23 Clamping cylinders 24 Torch ring 25 Cone feed plate 10 Countershaft bushings 11 Gear and pinion 12 Main shaft 13 Eccentric thrust bearing 14 Counterweight guard 15 Tramp Release assembly 16 Eccentric bushing 17 Eccentric 1 Locking bolt 2 Feed bowl hopper 3 Bowl 4 Cone Crushers HP Series Cone Crushers Pilot Crushtec

crusher 2 foot sh dimension bowl liner Mining

crusher 2 foot sh dimension bowl liner – Grinding Mill China Cedar s / EL Jay Rock Cone Crusher 36 STANDARD 48297591 899 Bowl Liner, C – Long cs series Cone Crusher Manganese Wear Parts 2 FT 5½ ft, and 7ft cone crushers for both standard and short head designs Our hydraulic locking post is designed with reliability Hydraulic ram bowl adjust Hydraulic gear turn the bowl during liner Spare wear parts for Symons® Cone Crushers Reliable 2 ft clay 1 ft soil 2 ft clay 1–2 ft drainage layer 6 in top soil 40–300 ft waste 1 ft drainage layer 006 in plastic liner w = head on liner (m) K s = hydraulic conductivity (m/s) For poor contact, use 115 in place of 021 Poor contact: no control over membrane wrinkling and poorLandfill Liner and Cover Systems: Design Guidelines A

Vertical Turbine Pumps Intro to Pumps

So the twostage unit would be capable of producing a flow of 1,000 GPM at 200 Ft TDH (100 Ft per stage) When talking about a vertical turbine with twostages, we would 6,759 crusher liner products are offered for sale by suppliers on Alibaba A wide variety of crusher liner options are available to you, such as graphic design, total solution for projects You can also choose from modern, contemporary crusher liner, as well as from 1 year, 5 years crusher liner, and whether crusher liner is waterproofcrusher liner, crusher liner Suppliers and 1 The Mn19Cr2Mo bowl liner is the patent product of YIPIN, China patent No: 4x Tests show that the ore processing capacities and the service time of it are about 20% higher than those of the international same products 2 YIPIN products are with accurate sizes and suit the crusher well 3Blow Liner and Mantle yppsj

Excel Premium Components 911 Metallurgist

2 ft • 7ft Standard Shorthead Hydraulic Locking Post Duckworth Lock Post Feed Hopper Bowl Bowl Liner Feed Cone UBolt Assembly Torch Ring Mainshaft Sleeve Adjustment Ring Spring Bolt Spring Mainframe Seat Liners Mainframe Liner Arm Guard Mainframe Gear Counterweight Eccentric Inner Eccentric Bushing Outer Eccentric Bushing Step Plates 21 Bowl liner 22 Hydraulic adjustment motor 23 Clamping cylinders 24 Torch ring 25 Cone feed plate 10 Countershaft bushings 11 Gear and pinion 12 Main shaft 13 Eccentric thrust bearing 14 Counterweight guard 15 Tramp Release assembly 16 Eccentric bushing 17 Eccentric 1 Locking bolt 2 Feed bowl hopper 3 Bowl 4 Cone Crushers HP Series Cone Crushers Pilot CrushtecA Hydraulic Workover Unit can provide an efficient solution to almost any completion or well intervention program PSI is committed to delivering the highest possible standards for quality, health, safety and environmental protection in all operations, for all operators • Liner installation under pressure ROTARY: 7 1/16” 6,600 ftlb:Production Solutions International Hydraulic

Hydraulically retrofitting mechanically adjustable cone

What is claimed is: 1 A method for retrofitting a mechanically adjustable cone crusher which includes an adjustable bowl assembly having a bowl liner, with said bowl assembly being held in position by a plurality of adjustment cap screws or locking posts each including a head and a threaded shaft, wherein the threaded shaft cooperatively engages a threaded bore of the bowl assembly, said assembly withstands the total hydraulic thrust as well as the rotor weight Selflubricated antifriction or tilting pad bearings can be utilized Additional Options • Enclosed lineshaft with oil or fresh water lubrication • Bowl liner (casing wear ring) 0 1 2 4 6 8 10 20 40 60 80 100 200 400 600 800 1000 50 40 30 20 10 7 5 4 3Vertical Axial Flow Pumps Patented brass bowl threads Patented “no creep” bowl clamp Patented mechanical “crusher duty” cone brake Patented liner retention assembly Low impact Tramp Iron Relief (TIR) system Pressure relief valves Large bore heavy duty relief cylinders Hydraulic “one button” chamber clearing Bronze field replaceable VSeat linersKODIAK CONE CRUSHERS Specification Sheet

Used 3 cu ft Vibratory Bowl Great Lakes Finishing

Our Location Great Lakes Finishing Equipment Inc 842 Schneider Drive South Elgin, IL 60177 7083455300 8478880995 info@greatfinishing Get Directions For finer crushing or reduction a Symons cone crusher the norm Symons are commonly used for secondary, tertiary or quaternary crushing They do this by a different chamber design which is flatter and by operating at about twice the rotational speed of a primary type gyratory crusher One of the first cone crushers had a direct drive vertical motor mounted above the spider with the drive shaft Symons Cone Crusher 911 Metallurgist6,759 crusher liner products are offered for sale by suppliers on Alibaba A wide variety of crusher liner options are available to you, such as graphic design, total solution for projects You can also choose from modern, contemporary crusher liner, as well as from 1 year, 5 years crusher liner, and whether crusher liner is waterproofcrusher liner, crusher liner Suppliers and Manufacturers

Blow Liner and Mantle yppsj

1 The Mn19Cr2Mo bowl liner is the patent product of YIPIN, China patent No: 4x Tests show that the ore processing capacities and the service time of it are about 20% higher than those of the international same products 2 YIPIN products are with accurate sizes and suit the crusher well 3A Hydraulic Workover Unit can provide an efficient solution to almost any completion or well intervention program PSI is committed to delivering the highest possible standards for quality, health, safety and environmental protection in all operations, for all operators • Liner installation under pressure ROTARY: 7 1/16” 6,600 ftlb:Production Solutions International Hydraulic Workover What is claimed is: 1 A method for retrofitting a mechanically adjustable cone crusher which includes an adjustable bowl assembly having a bowl liner, with said bowl assembly being held in position by a plurality of adjustment cap screws or locking posts each including a head and a threaded shaft, wherein the threaded shaft cooperatively engages a threaded bore of the bowl assembly, said Hydraulically retrofitting mechanically adjustable cone

SJT SJM SJP Sales Presentation Sulzer

Fabricated bowl and suction bell construction available A replaceable case liner is offered as an option in the bowl to increase bowl life when abrasive fluids are pumped It also reduces maintenance cost An optional strainer restricts entry of foreign objects into the bowl assembly with diverse materials, seals, and hydraulic performance for the most rigorous duties Each pump series has distinct design features Casing or Bowl Impeller Frame Plate Liner Insert or Back Liner Casing or Bowl Seal Clamp Ring Adapter Plate SERIES S, H, AND L 240 ft [73 m] Flows to: 22,000 gpm [5,000 m3/hr] Working pressures to: 300 Standard Pump Product Catalog Schurco Slurry Component identification 2ft l 3ft l 4ft l 4¼ ft l 5½ ft l 7ft Hydraulic Locking Post Duckworth Lock Post Feed Hopper Bowl Feed Cone UBolt Assembly Adjustment Cap Adjustment Ring Spring Bolt/Spring Torch Ring Mainshaft Sleeve Bowl Liner Mantle Head Baffle Ring Mainshaft Counterweight Gear Eccentric Inner Eccentric Bushing Outer Eccentric HIGH PERFORMANCE PARTS Symons series cone crushers

Used 3 cu ft Vibratory Bowl Great Lakes Finishing

Our Location Great Lakes Finishing Equipment Inc 842 Schneider Drive South Elgin, IL 60177 7083455300 8478880995 info@greatfinishing Get Directions Hydraulic actuation makes these cutters efficient and easy to use The exclusive indicator bushing triggers a distinct pressure drop, giving an obvious and unmistakable indication that the cut is Fishing Services Catalog Weatherford History of Hydraulic Workover Hydraulic Workover “HWO” is a well workover performed using a hydraulic workover (snubbing) unit to run and/or pull tubulars – with or without surface pressure present on the wellhead Hydraulic Workover Techniques in use since 1920’s First Hydraulic Units developed in 1959 2 3Hydraulic workover and snubbing solutions, رضا مصطفوی طباطبایی