Recent Patents on Thin Coal Seam Mining Equipment:

Recent Patents on Thin Coal Seam Mining Equipment Buy Article: $6800 + tax Background: China's thin and extremely thin coal seam resources are widely distributed and rich in reserves These coal seams account for 20% of the recoverable reserves, with 983 billion tons of industrial reserves and 615 billion tons of recoverable reserves The following equipment may be used for coal shearing and loading in a low seam Our experts are ready to design and supply other mechanized complexes corresponding the specific geological seam conditions as well Leaflet Complex supplies of coalmining equipment for low coal seams Complex supplies of coalmining equipment for low Aiming at thin coalseam mining with soft roof,soft coalseam,soft floor and complex geological condition,applying theoretical analysis,computer aid design,onthespot survey to innovating and integrating key fullmechanized mining technology,on the basis of analyzing domestic and foreign technologies,new equipments lectotype and design principles of powered support and coal cutter was Thin Coalseam Mining Technology and Equipment

ultra thin coal seam, fully mechanized mining

Sichuan Dazhu Coal Electricity (Group) Co, Ltd, developed the application of ultra thin coal seam mining equipment and the high efficiency of fully mechanized mining technology in mining area was first time realized in 055~08 m seam to effectively improve the efficiency, mechanization and automation of coal mining The Mining Machinery Division of Ostroj as is an established manufacturer of mining machinery and specialized equipment for coal mining We manufacture high quality shields, AFCs, BSLs, Boot Endsand associated equipment for the most demanding coalface operations, as well as specialist equipment for steep seam Mining Machinery and Equipment for Coal Mining development of lowprofile mining equipment, fully mechanized mining of thin coal seams under the complex geological conditions was achieved The development equipment has great potential to be widely applied in coal mines with similar conditions Keywords: Thin coal seam, Fully mechanized coal mining, Coal shearer,Fully mechanized coal mining technology for thin coal

Selected Mining Suppliers Mining Process Equipment

HMG100/111–TWD thin coal seam electric haulage shearer is frequency conversion speed regulating electric haulage shearer which comes out on the foundation of HMGI00T shearer Mining Height(m):0512 Cutting Depth(m):0810 Suitable Mining Publication: Experiments on Personal Equipment for Low Seam Coal Miners: IV Incorporating Coiled Cord Into Cap Lamp Battery Cords Keywords: Biomechanical hazards Cap lamps Equipment design Ergonomic design Low seam mining This page Experiments on Personal Equipment for Low Seam The MB470 is a bolter miner which can cut whilst simultaneous bolting roof and ribs This continuous miner can achieve up to 7 m/per hour of fully developed roadway Joy Shuttle Cars, shuttle cars are capable of transporting up to 15 tonnes coal at a time from the continuous miner Mining Operations – Kestrel Coal

Complex supplies of coalmining equipment for low

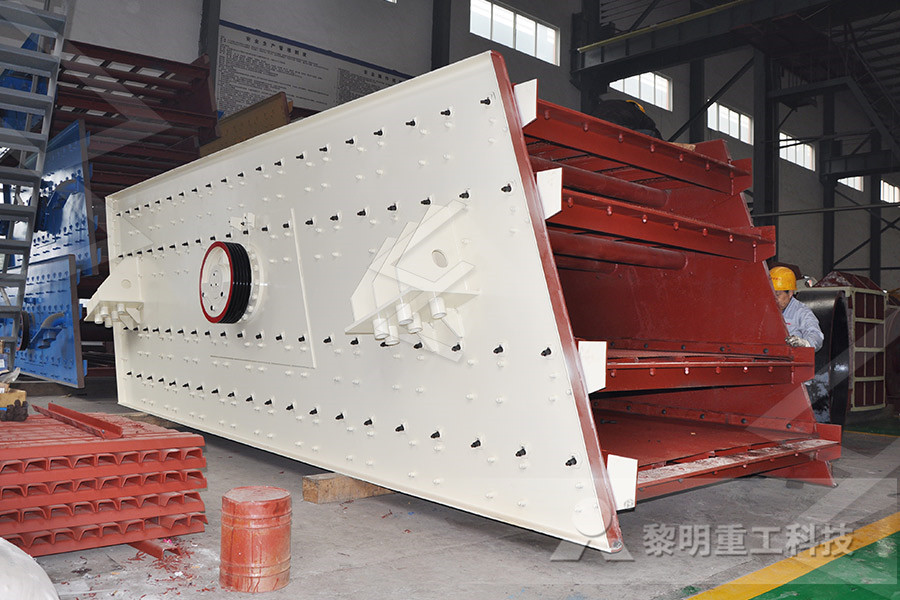

This coal shearing and loading complex is designed for low coal seams of thickness from 07m to 16m Seam parameters: Seam thickness: from 07m to 12m up to 60Mpa Dip along the face: ±25° Dip in direction of mining: 25°/+5° Max seam length: 300 m The following equipment may be used for coal shearing and loading in a low seamLow coal seam mining ground adjustment Our advantages The longwall coal mining technology has been successfully applied in coal mine with thickness of 08m, the maximum dip angle 45 ° Low coal seam comprehensive mechanized mining range 045m ~ 25m Low Coal Seam Longwall Coal Mining Units Equipment Low coal seam series drum electric Low coal seam Longwall mining,longwall mining,low Sichuan Dazhu Coal Electricity (Group) Co, Ltd, developed the application of ultra thin coal seam mining equipment and the high efficiency of fully mechanized mining technology in mining area was first time realized in 055~08 m seam to effectively improve the efficiency, mechanization and automation of coal mining in ultra thin coal seam ultra thin coal seam, fully mechanized mining

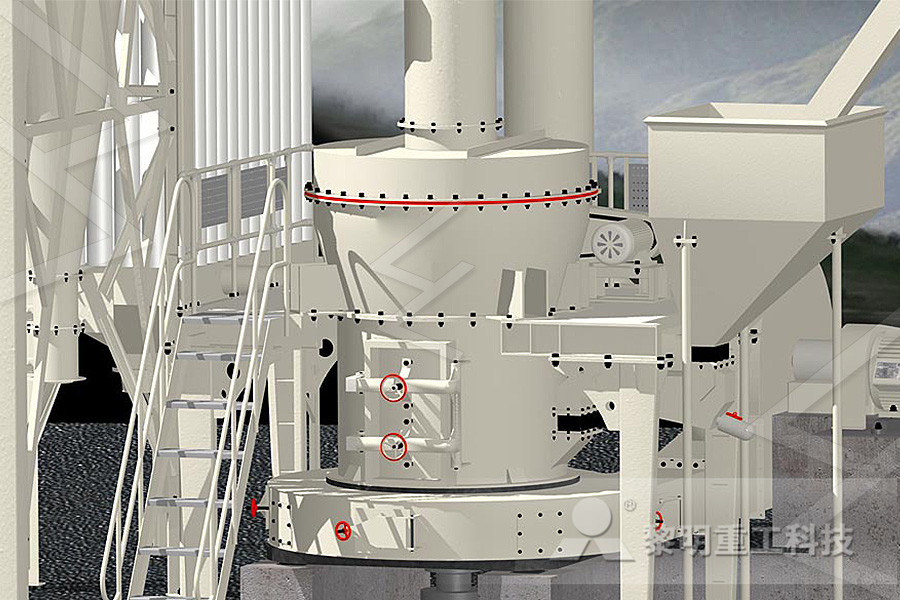

Mining Equipment Overview ALPHA

Our mining equipment ranges from surface mining (openpit mining) to underground mining Underground loaders (LoadHaulDump machines): 12~20 tons capacity, electrical or diesel, remote controls optional Low Coal Seam Mining technology: steep/low coal seam comprehensive mechanized mining range 03~25m, seam angle 30℃~90℃longwall mining : equipment : Cutting Machines Shearer Cutting Drums and ancillaries : Equipment The pick lacing is set to optimize cutting for the seam being worked, while the vanes are used to move the coal efficiently from the cutting area onto the AFC Another device used to improve coal loading is a "cowl" This is a curved steel Equipment underground COALThe hard rock parting contained in thin coal seams constrains the development of highefficiency mining due to high level of equipment wear and low mining advance rateTo achieve safe and highefficiency mining in thin coal seam with such complex geological conditions, an innovative mining approach using pressure regulation was proposed to substitute traditional deephole blasting technique to An innovative approach to thin coal seam mining of

160 China Coal Mining Equipmentchinacoal03 ideas

chinacoal03 Mining Machinery Shearer Loader for Longwall Coal Mining Application MG132/320WD series coal shearer is suitable for thick coal seam mechanized mining face,cutting height range from 085~155m Performance and characteristic Used in mining the coal seam of 085155m The speed regulator is hydraulicdriven,moves on trail @misc{etde, title = {Mechanization systems in shortwall coal seam mining} author = {Sikora, W, Jaszczuk, M, and Siwiec, J} abstractNote = {Discusses use of shortwall mining in selected countries and prospects for shortwall mining in Poland The following aspects are analyzed: room and pillar mining, room and pillar mining with mobile breaker line supports, shortwall mining using Mechanization systems in shortwall coal seam mining Thick coal seam is the main coal seam to achieve high efficiency coal mining In this chapter, the common mining methods for thick coal seams are introduced There is a largecuttingheight mining method and a topcoal caving mining method Also, the ground control for the thick coal seam mining is described in this chapterThick seam coal mining and its ground control

Economic Surface Mining of Multiple Seams

study of economics, cutoff grades and ratios, equipment capabilities, l>«Iuing and selective milling pmctices This paper is concerned primarily with mullipJeseam mining of biluminous coal The research has led 10 Ibe development of an ~nomic decisionmaking model for use as a Jllytoday 1001 10 aid mine operators and pitThis coal shearing and loading complex is designed for low coal seams of thickness from 07m to 16m Seam parameters: Seam thickness: from 07m to 12m up to 60Mpa Dip along the face: ±25° Dip in direction of mining: 25°/+5° Max seam length: 300 m The following equipment may be used for coal shearing and loading in a low plex supplies of coalmining equipment for low Sichuan Dazhu Coal Electricity (Group) Co, Ltd, developed the application of ultra thin coal seam mining equipment and the high efficiency of fully mechanized mining technology in mining area was first time realized in 055~08 m seam to effectively improve the efficiency, mechanization and automation of coal mining in ultra thin coal seam ultra thin coal seam, fully mechanized mining

Mining Equipment Overview ALPHA

Our mining equipment ranges from surface mining (openpit mining) to underground mining Underground loaders (LoadHaulDump machines): 12~20 tons capacity, electrical or diesel, remote controls optional Low Coal Seam Mining technology: steep/low coal seam comprehensive mechanized mining range 03~25m, seam angle 30℃~90℃China Shearer supplier, Thin Coal Seam, Coal Cutter Manufacturers/ Suppliers Chongqing Yongrong Machinery Manufacturing Co, LtdChina Shearer manufacturer, Thin Coal Seam, Coal The hard rock parting contained in thin coal seams constrains the development of highefficiency mining due to high level of equipment wear and low mining advance rateTo achieve safe and highefficiency mining in thin coal seam with such complex geological conditions, an innovative mining approach using pressure regulation was proposed to substitute traditional deephole blasting technique to An innovative approach to thin coal seam mining of

160 China Coal Mining Equipmentchinacoal03 ideas

chinacoal03 Mining Machinery Shearer Loader for Longwall Coal Mining Application MG132/320WD series coal shearer is suitable for thick coal seam mechanized mining face,cutting height range from 085~155m Performance and characteristic Used in mining the coal seam of 085155m The speed regulator is hydraulicdriven,moves on trail Through partnership among coal producers, equipment manufacturers, and research institutions, China developed the ultrathick seam longwall mining system by stages: prior to 2005, development and application concentrated on 43 to 55m (14118 ft) thick seams; in 2007, the system applied to 63m (207ft) thick seams was introduced; and in Ultrathick Seam Longwall Mining in China Coal Age @misc{etde, title = {Mechanization systems in shortwall coal seam mining} author = {Sikora, W, Jaszczuk, M, and Siwiec, J} abstractNote = {Discusses use of shortwall mining in selected countries and prospects for shortwall mining in Poland The following aspects are analyzed: room and pillar mining, room and pillar mining with mobile breaker line supports, shortwall mining using Mechanization systems in shortwall coal seam mining

Thick seam coal mining and its ground control

Thick coal seam is the main coal seam to achieve high efficiency coal mining In this chapter, the common mining methods for thick coal seams are introduced There is a largecuttingheight mining method and a topcoal caving mining method Also, the ground control for the thick coal seam mining is described in this chapter study of economics, cutoff grades and ratios, equipment capabilities, l>«Iuing and selective milling pmctices This paper is concerned primarily with mullipJeseam mining of biluminous coal The research has led 10 Ibe development of an ~nomic decisionmaking model for use as a Jllytoday 1001 10 aid mine operators and pitEconomic Surface Mining of Multiple Seams