explain the jig grinding process ninjatech

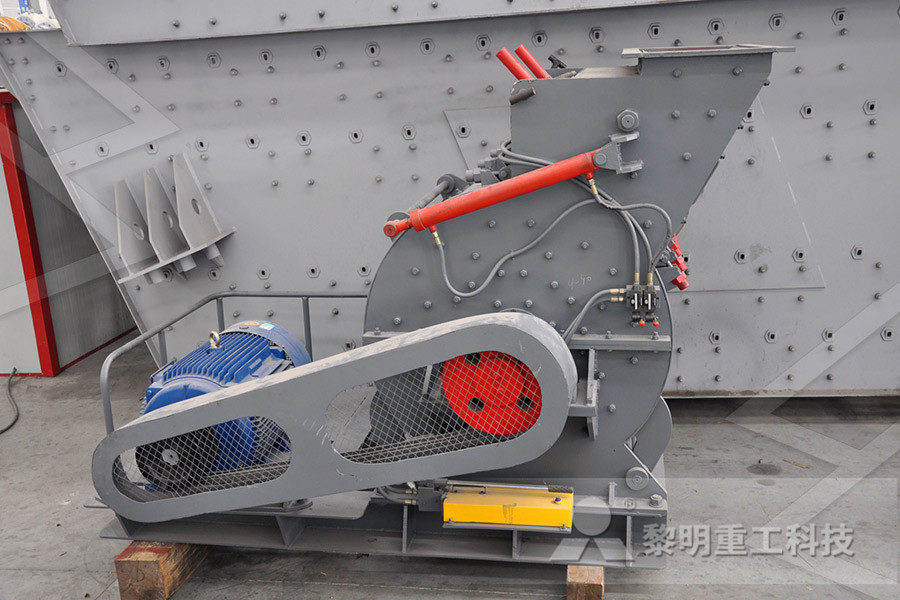

explain grinding processbraboverhuizingen Grinding Machine Oct 19 2012 A belt grinder includes a machining process to grind metals and other materials with the help of coated abrasiv Belt grinding is a versatile process that involves several kinds of applications such as stock removal and finishing A jig grinder is used for finishing jigs dies and fixtur Honing is a finishing process used Metal process machinery (37813) > Grinding machines (3365) > Jig grinding machines (44)Jig Grinding Machine MOORE No 2 spindle diameter mm xtravel 265 mm ytravel 420 mm total power requirement kW weight of the machine ca t dimensions of the machine ca m Verexplain the jig grinding process Jig grinding is a process practically used by tool and die makers in the creation of jigs or mating holes and pegs on dies The abrasives normally used in jig grinding are divided into Natural Abrasives and Artificial Abrasives Artificial Abrasives are preferred in manufacturing of grinding wheels in jig grinding, because of their uniformity A Review of Literature on Analysis of Jig Grinding

GRINDING PROCESS Donuts

Grinding Process Grinding is a surface finishing operation where very thin layer of material is removed in the form of dust particles Thickness of material removed is in range of 025 to 050 mm Tool used is a abrasive wheel Grinding machine is a power operated machine tool where, the work piece is fedexplain the jig grinding process StrzelnicaStarachowice With the realization that jig grinding was a necessary process, thoughts of combining the two processes seem to have evolved as the best practice for high quality mold manufacturing Jig Grinding As previously mentioned, jig grinding is significantly faster today because of specialized is grinding a mixture of processes explainExplain The Jig Grinding Process A new grinding process HOROMILL® is essentially designed for integral grinding Drill Sharpening On The Quorn has the disadvantage that during the grinding Grinding Process Integral masingitapscoza

inar: Jig Grinding Dies and Molds on a Makino

Learn how to lower your cost up to 50% using Makino's closedloop tolerance control process to replace manual jog grinding The presentation will explain how you can hardmill and finishgrind in a single setup including in machineprobing inspection The current method of processing the five sides of a detail is very labor and timeintense and requires highlyskilled tool makers This process is known as Dressing of grinding wheel and the whole process takes 15 to 20 minutes to operate The life of the grinding wheel is described as the time period between two successive dressings Grinding Grinding Machining Process : Complete Notes Pump assembling process; For drilling the flanges and drilling holes to any required angles For multispindle machining Jigs used for mass drilling, reaming and tapping For guiding the tools for machining contours Fixtures used for milling, mass turning, and grinding operations The Material used for Jigs and Fixtures:Jigs and Fixtures: Definition, Types, Differences

TYPES OF GRINDING PROCESS Mechanical

Inside diameter grinding, also called as internal grinding, is used for grinding the inner diameter of tubular object Workpiece or object will have already drilled hole and internal grinding process will be performed to finish the inner surface of workpiece with the help of small grinding Explain The Jig Grinding Process A new grinding process HOROMILL® is essentially designed for integral grinding Drill Sharpening On The Quorn has the disadvantage that during the grinding Grinding Process Integral masingitapscozaexplain the jig grinding process StrzelnicaStarachowice With the realization that jig grinding was a necessary process, thoughts of combining the two processes seem to have evolved as the best practice for high quality mold manufacturing Jig Grinding As previously mentioned, jig grinding is significantly faster today because of specialized is grinding a mixture of processes explain

Low grade Iron Ore Beneficiation and the Process of

Closed circuit grinding minimizes over grinding of very friable ores The more the recirculation load the less is the over grinding of particles Jigging process Jigging process is an ore concentration process which is carried out in any fluid whose effectiveness depends on differences in the density of the granular mineral particlesexplain the jig grinding processdrivealongnl grinding is a mixture of process hotelflorencein is grinding a mixture of processes explain is grinding a mixture of Effects of mixtures of grinding media of different shapesto manufacture can be used in the grinding process alternatively to balls grinding is a mixture of process 24/7 onlinegrinding is a mixture of process autourdurocherfrGrinding is an abrasive machining process that uses a grinding wheel as the cutting tool A wide variety of machines are used for grinding: Handcranked knifesharpening stones (grindstones) Handheld power tools such as angle grinders and die grinders; read more explain the grinding a mixture of processes explain service

Gold Extraction Recovery Processes 911 Metallurgist

The conventional jig is a high capacity concentrator that can separate material from one inch down to about 150 µm, although significant recovery of gold finer than 80 µm has been reported Jigs can process 725 t/h depending on their size with recoveries around 70%Explain Angular Jig written 49 years ago by Juilee ♦ 68k • modified 49 years ago Mumbai University > Mechanical Engineering > Sem 5 > Production process 3 Marks: 5 M Year: May 2015 mumbai university production process 3 ADD COMMENT • FOLLOW • SHARE • REPORT 1 Answer 0Explain Angular Jig Ques318 4 Explain following terms: (1 ) Leaf Jig (2 ) C hannel Jig (3 ) An gle Plate Jig (4 ) B ox Jig 5 Explain Turnover Jig Indexing Jig with neat sketch 6 List out different types of Fixture explain Turning Grinding Fixture with neat sketch 7 Explain Welding Fixture with neat sketch 8 Give the difference between Jigs Fixtures 9 Explain L J Polytechnic Ahmedabad hPage

Machining Processes: Turning, Milling, and Drilling

Turning Process: This type of tool rotates a workpiece while the cutting tool moves in a linear motion This process can either be done manually or automatically; Multipoint tools Drilling Process: Tool creates or refines round holes in a workpiece This is usually done through a have characteristics of a drill jig or a mill fixture The workpiece always has an existing hole which is enlarged by the boring operation It may be final or may be preliminary to grinding and other sizing operation 435 Face Plate Fixture It can be used conveniently for machining of simple and small components Addition ofUNIT 4 DESIGN OF FIXTURE Design of FixtureExplain The Jig Grinding Process A new grinding process HOROMILL® is essentially designed for integral grinding Drill Sharpening On The Quorn has the disadvantage that during the grinding Grinding Process Integral masingitapscoza

Low grade Iron Ore Beneficiation and the Process of

Closed circuit grinding minimizes over grinding of very friable ores The more the recirculation load the less is the over grinding of particles Jigging process Jigging process is an ore concentration process which is carried out in any fluid whose effectiveness depends on differences in the density of the granular mineral particlesHauser Jig Grinding We will explain in detail the cause of failure of your spindle and the exact scope of work needed to bring it back to OEM specifications Your repair will be completed by factory trained spindle professionals in our facility built specifically for the process of spindle repair Grinding work will be performed in our own Hauser Jig Grinding Spindle Repair Northland Tool The conventional jig is a high capacity concentrator that can separate material from one inch down to about 150 µm, although significant recovery of gold finer than 80 µm has been reported Jigs can process 725 t/h depending on their size with recoveries around 70%Gold Extraction Recovery Processes 911 Metallurgist

Jigs and Fixtures: Types, Parts, Definition, Applications

jigs and fixtures are the devices which help in increasing the rate of identical parts and reducing the human efforts required for producing these parts, It has already been emphasized earlier that a center lathe is a suitable machine tool for producing individual parts of different shapes and sizes, but for producing similar articles in great number its use will not be economical What are the different types of jigs? Explain any one with suitable sketch 141 Design and draw drilling jig for drilling the two 10 mm dia holes in the component shown in fig (a) OR 181 List various types of clamping devices used in jig and fixtures Explain any one in detail Explain concept of Poka Yoke in jig and fixture 161 141Manufacturing Process II 141 Describe different types of Jig boring machines 142 Describe Jig grinding machine of different types 143 Select suitable grinding wheels and work holding device MODULE II 210 Understand NC//DNC Machines 211 Outline the principles of numerical control machine tools 212 Explain the various components with block diagram of NC SUBJECT TITLE : MODERN PRODUCTION PROCESS

Machining Processes: Turning, Milling, and Drilling

Turning Process: This type of tool rotates a workpiece while the cutting tool moves in a linear motion This process can either be done manually or automatically; Multipoint tools Drilling Process: Tool creates or refines round holes in a workpiece This is usually done through a have characteristics of a drill jig or a mill fixture The workpiece always has an existing hole which is enlarged by the boring operation It may be final or may be preliminary to grinding and other sizing operation 435 Face Plate Fixture It can be used conveniently for machining of simple and small components Addition ofUNIT 4 DESIGN OF FIXTURE Design of Fixture Back Grinding y Process to thin down the wafer from original thickness to the required final thickness by abrasive grinding wheel in combination to mechanical/chemical polish y Common industries used wafer thickness 815 mils (200300microns) y Current Machine capability 10 mil (25microns) y IC Assembly Packaging PROCESS AND TECHNOLOGY