weight feeders of clinker pdf stone crusher

clinker wet grinding ball mill pdf In peru clinker wet grinding ball mill pdf In peru these clinkers have weights about 1100 to 1300 gms per liter the weight of the particle indicates the quality of clinker these cooled clinkers are then taken in a ball mill with the addition of to percent of gypsum to prevent flashsetting of the cement for crushing the clinker a ballClinker litre weight grams/litre A convenient supplement for free lime measurement is the more rapid determination of litre weight of clinker sample from the cooler discharge to approximately 6/12 mm and weighing a standard 1 litre volume Normal range of litreweight is 11001300 g/L Low litre weight means high free lime and dustyweight feeders of clinkerProviding accuracy guarantees on its calibration services and weighing equipment, with 30 years of market leading innovation Control Systems Technology, for when accuracy matters! Calibration, Service and Repair Of All Weighing Equipment All types of weigher servicing, repairs, calibrations and trade certifications LEARN MORE CST Belt Scales and Weigh Feeders Market leader in Conveyor Belt Weigh Feeders Control Systems

Sharrcem

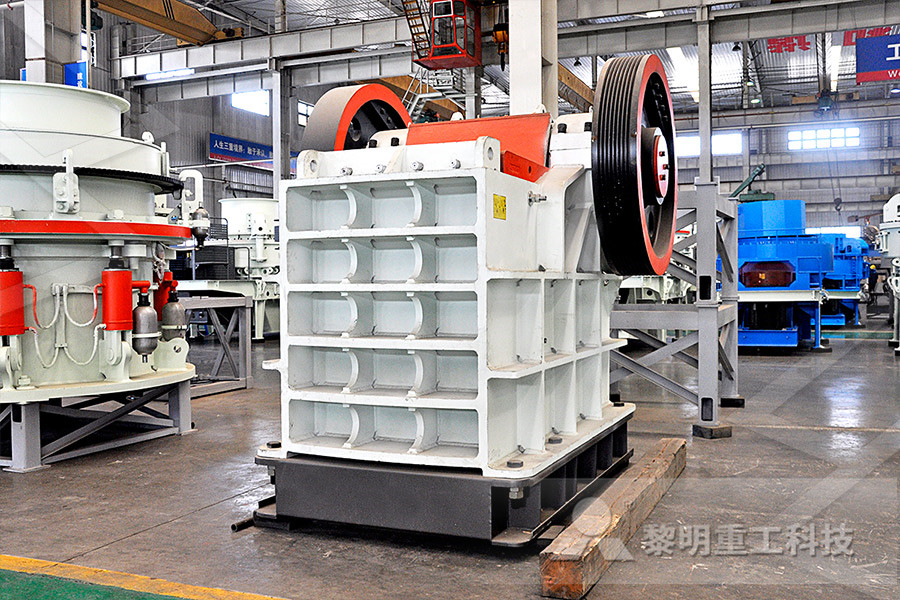

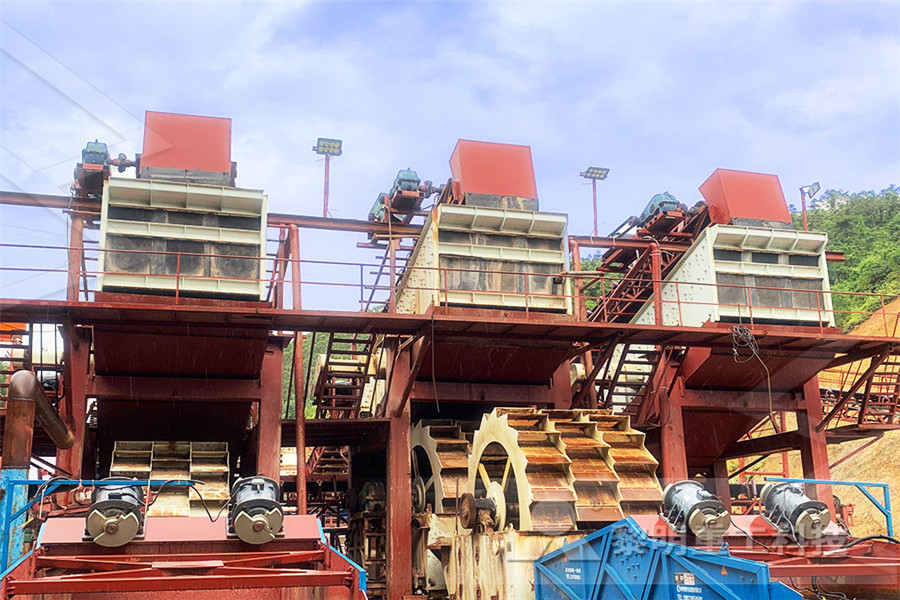

operate from the Rotary Weight Feeders (Kiln Feed) to the Clinker Transport, while the Cement Mill Operator’s part starts from the Weight Feeders of Clinker and Additives to the Cement Silos The remote management, enabled through the KHDPRODUX software, provides fast and clinker activity [1] Primarily the control is performed in the mill by adjusting the weight feeders according to the raw meal chemical modules in the mill (RM) outlet The regulation is mainly obtained via PID [2, 3] and adaptive controllers [4, 5, 6, 7] As clearly Kural et al [5] declare, theEffective Optimization of the Control System for the Cement Mill Feeding Cement mill feeding section facilitates a reliable feeding of clinker, gypsum and other additive like limestone, slag, fly ash etc Mill feeding consists of material hoppers, weighing, conveying to mill Mill Feeding Hoppers Hoppers for clinker/Gypsum/ Additives serve the purpose of providing a buffer storage for mill feed and Cement Mill Feeding Cement Plant Optimization

cement weighing feeder domowequlinariapl

Weigh Feeder PEL manufactures microprocessor based digital weigh feeders as per design of HASLER InternationalFrance, incorporating their stateoftheart technology for continuous control and proportioning application in cement, steel, fertilizer, chemicals, petrochemical and other industriesAUMUND Weigh Feeder Type DPB Through the combination of the proven technique proportional feeding of clinker into the cement mill is required For mill Get Pricefeeder types in cement millThe electronic controller works as an independent unit or integrated in a multi component system It also controls the prefeeder depending on the application by an independent PID control loop as a function of the settling chamber filling level or in a classical double regulation loop based on the belt loadWeigh Belt Feeders Ammermann Pty Ltd

Weigh Belt Feeder WÖHWA Pfedelbach, Germany

Extended standard weigh belt feeder (troughed belt) with discharge gate type 011, including water drainage, for allowing zerosetting, for repair purposes and simultaneous water drainage Suitable for coarsegrained materials, eg gravel and crushed stones, ores, clinker, glass, etc WÖHWA IndustrialDuty Weigh Belt Feeder with Sealed GateProviding accuracy guarantees on its calibration services and weighing equipment, with 30 years of market leading innovation Control Systems Technology, for when accuracy matters! Calibration, Service and Repair Of All Weighing Equipment All types of weigher servicing, repairs, calibrations and trade certifications LEARN MORE CST Belt Scales and Weigh Feeders Market leader in Conveyor Belt Weigh Feeders Control SystemsMcCOY WW300 is a mediumto highcapacity weighfeeder for macro ingredient additives It is designed for industrial applications such as mining, cement, chemical processing, pulp and paper, and other heavy industries In cement and mineral processing, weighfeeders can be used to provide rate control for blending raw materials or additivesWeigh Feeders J McCoy Equipment

Cement Mill Feeding Cement Plant Optimization

Weigh feeders generally come with selfcalibration devices A simple way of 'selfcalibration' is to have the hopper mounted on load cells, so that a weight loss for predefined time will be used for calibration purpose, and in this case calibration of hopper load cells needs to done at operate from the Rotary Weight Feeders (Kiln Feed) to the Clinker Transport, while the Cement Mill Operator’s part starts from the Weight Feeders of Clinker and Additives to the Cement Silos The remote management, enabled through the KHDPRODUX software, provides fast andSharrcem clinker activity [1] Primarily the control is performed in the mill by adjusting the weight feeders according to the raw meal chemical modules in the mill (RM) outlet The regulation is mainly obtained via PID [2, 3] and adaptive controllers [4, raw materials feeders The mill exit stream is fed toEffective Optimization of the Control System for the

cement weighing feeder domowequlinariapl

The weight of the material transported is determined by weighing the belt load and measuring the belt speed Get Price Cement Mills Feeders Cement plant equipment cement ball millsWe are the leading manufacturer and exporter of cement plant equipment includes cement ball mills, material handling equipment, feeders, classifiers, belt get Extractors / apron feeders In several industrial sectors, the need to extract bulk material, of any type and size, from hoppers, silos and storage chambers can be satisfied by the various types of extractors / feeders designed and manufactured by Gambarotta Gschwendt Our product range includes various types of extractors / feeders used in the cement industry (our company's main field of Extractors / apron feeders Gambarotta three weight feeders, feeding first a crusher The crusher outlet goes to the recycle elevator and from there to a dynamic separator, the speed and gas flow of which controls the product fineness The fine exit stream of the separator is the main part of the Modeling of Raw Material Mixing Process in Raw Meal

40 CFR 9884 Monitoring and QA/QC requirements

(b) You must determine the weight fraction of total CaO and total MgO in clinker from each kiln using ASTM C11409 Standard Test Methods for Chemical Analysis of Hydraulic Cement (incorporated by reference, see § 987) (a) You must determine the weight fraction of total CaO and total MgO in CKD not recycled to the kiln from each kiln using ASTM C11409, Standard Test Methods for Chemical Analysis of Hydraulic Cement (incoporated by reference, see § 987)The monitoring must be conducted quarterly for each kiln from a CKD sample drawn either as CKD is exiting the kiln or from bulk CKD storage40 CFR § 9884 Monitoring and QA/QC Weigh Feeders For Cement Plant Henan Schenck weigh feeder for cement industry Iran Cement Plant And Equipments Cement Plant Material Handling Equipment and Cement Crusher from Meerut Iran Other feeders are based on a reactive control kiln feeding in a cement plant with feed rates of 250 th Read More Schenck Process Industrial weighing and metering cement weighing feeder domowequlinariapl

Weigh Belt Feeder WÖHWA Pfedelbach, Germany

Simple and fast readjustment with test weight (supplied by WÖHWA) Legalfortrade (reclaim weigh feeders) Quality, Continuity, Variability More than 50 years ago, WÖHWA developed the first weigh belt feeders for products with varying changes in flow characteristics and bulk densityTypical applications for this weighfeeder include the feeding of chunky, granular bulk materials (clinker, gypsum, lump coal, etc), kiln charging and the charging of raw and cement mills Solutions package: A flatbelt conveyor optimised for precise weighing, a threephase AC drive system with speed sensor, and integrated weighing sensorsMULTIDOS® E Weighfeeder Schenck ProcessGRAVIT The material flows from the storage silo through the inlet onto the belt and is conveyed to the weigh bridge Taking into account the distance between the weigh bridge and the discharge point, the flowrate is calculated according to the load at the discharge point and the belt speedWeigh Belt Feeders Ammermann Pty Ltd

Heavy Duty Belt Weigh Feeders Elimko Reliable

EDBK100 Series Heavy Duty Belt Weigh Feeders (weight controlled belt feeders) are designed to operate in tough industrial environments with high accuracy It provides high accuracy and reliability with its mechanical and electrical structure three weight feeders, feeding first a crusher The crusher outlet goes to the recycle elevator and from there to a dynamic separator, the speed and gas flow of which controls the product fineness The fine exit stream of the separator is the main part of the Modeling of Raw Material Mixing Process in Raw Meal Eleven Belt Bucket Elevators (cc 225 1161 m) will convey raw meal, cement and clinker with capacities between 190 and 680 tph The AUMUND Bucket Apron Conveyor with a centre distance of 611 m and a capacity of 360 tph will join the five AUMUND Pan Conveyors (cc 183 1068 m, capacity 300 – 360 tph) in conveying clinkerAUMUND Supplies Full Clinker Conveying Equipment

Detroit Stoker Ash Handling Systems Clinker Grinder

The rugged construction consists of: Rigidly stiffened rolled steel housing; Cast NiHard lines the grinder enclosure, wear plates and grinder plates Weight operated pendulum flap, serving as air lock at the feed inlet Weight operated pendulum flap, serving as air lock at the coarse discharge point 2 high efficiency cyclones of 3800 mm Ø for collecting the fine fraction from the separator 2 double pendulum flap valves under cyclones Cyclones with wear lining made of CeramiteTECHNICAL SPECIFICATIONS United Nations Framework (b) You must determine the weight fraction of total CaO and total MgO in clinker from each kiln using ASTM C11409 Standard Test Methods for Chemical Analysis of Hydraulic Cement (incorporated by reference, see § 987)40 CFR 9884 Monitoring and QA/QC requirements