composition of a hammer mill Induzin

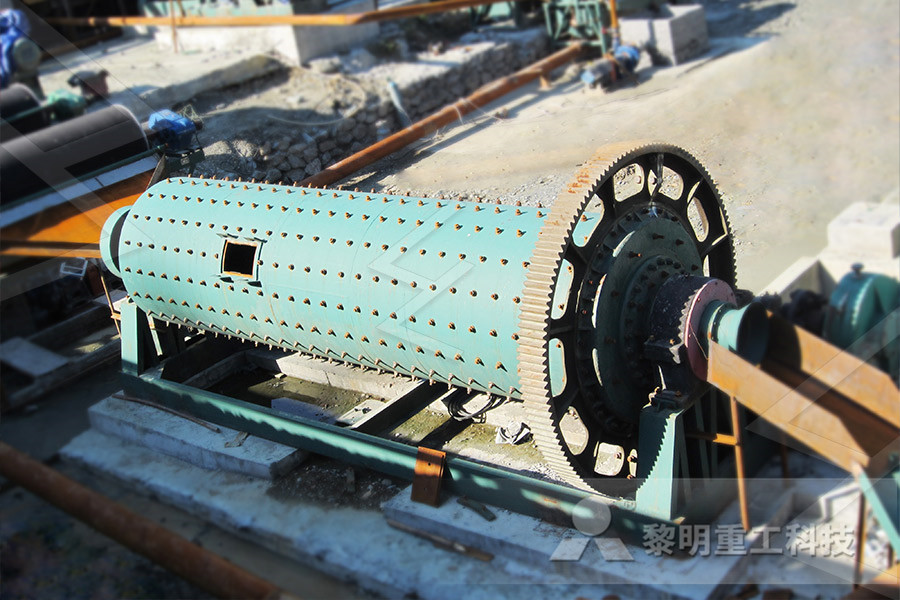

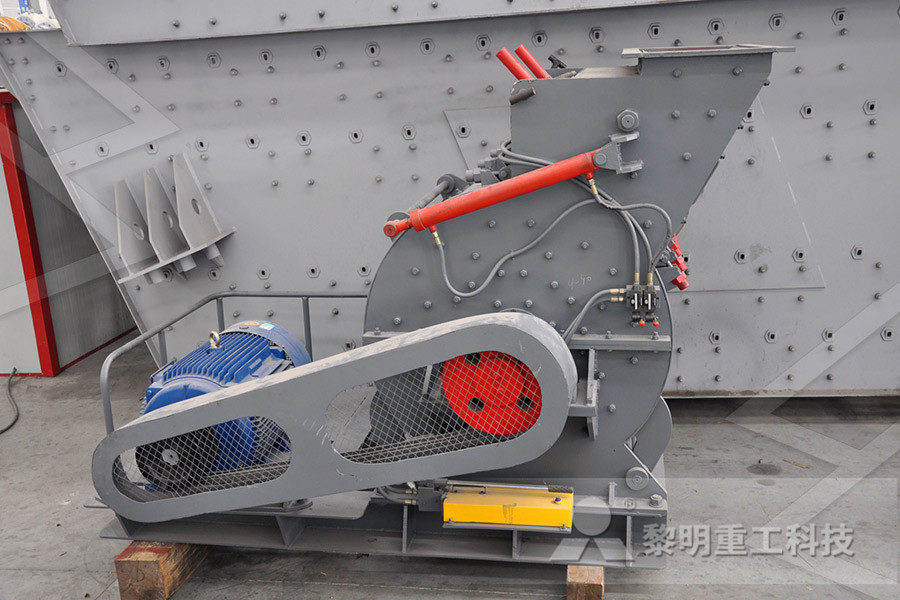

Such hammer crusher is mainly composed of the frame, rotor, grate bar, beater plate, adjusting device, etc Hammer mill,Hammering machine,Hammer mill crusher,Hammer The structure of the hammer mill crusher is sealed up so that there is no powder pollution inside the crushing workshop and no ash leakage in the machine 4composition of high chrome coal mill ball composition of hammermill liner Si Troughs Crusher Cone Liners Grates, Hammer Mill Hammers Liner Plat Live a , Chemical composition of wearresistant cast irons of working layer position of hammermill liner HAMMER MILL MODEL: ACHM Hammer mills are used to grind screening, grain husk etc The material is fed by a feeder The grinding process is made between moving blades and perforated sleeve The rotor consists of a steel shaft, hammers on the shaft Rotor shaft is heat treated and felt holes are sand blasted Hammers are strenghten abrasHAMMER MILL MODEL: ACHM Ana Milling

Influence of the granulometric composition of coal

The influence of the granulometric composition of coal batch on the energy requirements of a hammer mill is considered Means are proposed for reducing the energy consumption in crushing coal batch that already has a high content of the final size class11 The hammer mill of claim 10 additionally comprising a cylindrical screen fitted around said mill 12 The hammer mill of claim 11 wherein the distance between said mill hammers and said screen ranges from about 006 to about 1 inch 13 The hammer mill of claim 8 wherein said base plate is fitted onto a rotatable shaft 14Hammer mill WeighTronix, IncDOI: 103103/SX Corpus ID: Influence of the granulometric composition of coal batch on the energy requirements of a hammer mill @article{Zaselskii2012InfluenceOT, title={Influence of the granulometric composition of coal batch on the energy requirements of a hammer mill}, author={V I Zasel’skii and G L Zaitsev and T A Zasel’skaya}, journal={Coke and Influence of the granulometric composition of coal

Hammer Mill Photos and Premium High Res Pictures

Find the perfect Hammer Mill stock photos and editorial news pictures from Getty Images Select from premium Hammer Mill of the highest qualityHammer Mills In wholewheat milling, a hammer mill can be utilized in conjunction with or without a roller mill A hammer mill utilizes the grinding action of impact to reduce the particle size of the material Material is forced through a screen of a selected opening size by rotating hammers evenly spaced on a Flour Mill an overview ScienceDirect Topics Description Depending on the application, hammers have either two or four wearing edges to provide maximum wear life Hammers should be rotated when the cutting edge is well rounded and the machine is not running at top performanceReplacement Hammers for Hammer Mills Schutte

composition of hammermill liner mepsystemfr

composition of high chrome coal mill ball composition of hammermill liner Si Troughs Crusher Cone Liners Grates, Hammer Mill Hammers Liner Plat Live a , Chemical composition of wearresistant cast irons of working layer in The hammer mill is made up of a monoblock steel body of reinforced construction supported on a bench with special antivibration dampers for fixing to the floor Circular sieves in two sections, easily exchangeable from the outside with the hammer mill in operationIndustrial hammer mill for feed millThese units offer approximately 1 to 2 tons (900 to 1,800kg) throughput per hour The ten included 15in (38mm) wide 8lb (36kg) hammers are made from wearresistant highchrome steel for long service life Production is higher and hammer life is enhanced by feeding 1in (25mm) materialPortable Hammermill Crushers Gilson Co

How hammer is made material, making, history, used

A hammer is a handheld tool used to strike another object It consists of a handle to which is attached a heavy head, usually made of metal, with one or more striking surfaces There are dozens of different types of hammers The most common is a claw hammer, which is used to drive and pull nailsHammer Mills In wholewheat milling, a hammer mill can be utilized in conjunction with or without a roller mill A hammer mill utilizes the grinding action of impact to reduce the particle size of the material Material is forced through a screen of a selected opening size by rotating hammers evenly spaced on a Flour Mill an overview ScienceDirect Topics Hammer mill crushing variables and malaxation time are studied through a two‐level factor factorial experimental design in order to assess the impact of these parameters and their interactions on olive oil extraction efficiency, overall quality, and minor components compositionInteractions Between Hammer Mill Crushing Variables

Journal of Mechanical Engineering Vol 16(2), 93107, 2019

materials into smaller sizes Hammermill crusher is located on the main axis of hammermill crusher machine [16] Currently, the material used to manufacture hammermill crusher is manganese steels which are durable and hard in spite of low carbon content This research focuses on manufacturing hammermill crusher with the addition of 375% Cu coal charge, hammer mill, granulometric composition, energy costs Abstract In conditions of fierce competition in the market of mining and metallurgical products the need to reduce its cost, which is achievable through optimization power consumption One way to solve this problem, in conditions transformation of industrial clusters and Experimental Studies of the Process of Crushing Coal The hammer mill is designed to give the particles velocities of the order of that of the hammers Fracture is either due to impact with the hammers or to the subsequent impact with the casing or grid Since the particles are given high velocities, much of the size reduction is by attrition (ie, particle on particle breakage), and this leads Impact Crusher an overview ScienceDirect Topics

Hammer Mill Perforated Screens Feed Mill

Hammer mills screens are used inside a hammer mill to seperate particle sizes Particle of small enough diameter that has been sucessfully grinded by the hammer mill passes through the screen and leaves the hammer mill with the aid of th pneumatic position of high chrome coal mill ball composition of hammermill liner Si Troughs Crusher Cone Liners Grates, Hammer Mill Hammers Liner Plat Live a , Chemical composition of wearresistant cast irons of working layer position of hammermill liner mepsystemfrHammer Mill Sieve Design Impacts Olive Oil Minor Component Composition Author: Polari, Juan J, Wang, Selina C Source: European journal of lipid science and technology 2019 v121 no10 pp e ISSN: 14387697 Subject: chlorophyll, crushing, extravirgin olive oil, free fatty acids, fruits, olives, peroxide value, phenols, volatile Hammer Mill Sieve Design Impacts Olive Oil Minor

Influence of the granulometric composition of coal

DOI: 103103/SX Corpus ID: Influence of the granulometric composition of coal batch on the energy requirements of a hammer mill @article{Zaselskii2012InfluenceOT, title={Influence of the granulometric composition of coal batch on the energy requirements of a hammer mill}, author={V I Zasel’skii and G L Zaitsev and T A Zasel’skaya}, journal={Coke and The hammer mill utilises metal arms that grind the grain by pushing it through a metal screen, with particle size altered through the use of different screen sizes Current commercial screen sizes can vary depending on the range of animal feed being produced At present, the QAF feed mill uses a 325 mm screen, while other feed mills mayInfluence of hammer mill screen size and grain source Hammer Crusher,Hammer Mill Crusher,Hammer Stone, hammer material composition,Impact Crusher of European Type Impact Crusher of European Type is widely applied in mining, transportation, energy, construction and chemical industry They are ideal choice for,More MTW Series Trapezium Mill MTW Series line hammer crusher impact crusher hammer material composition ME

Ratios of Bran Pulverized by Hammer Mill or Jet Mill

31 Composition of Wheat Bran Pulverized by a Hammer Mill or Jet Mill and that of Wheat Flour Substituted with Various Ratios of Bran The particle size and color of bran pulverized by a hammer or jet mill are shown in Table1 The particle size of jet mill bran (JMB) was significantly smaller than that of hammer mill bran (HMB) (p 005)These units offer approximately 1 to 2 tons (900 to 1,800kg) throughput per hour The ten included 15in (38mm) wide 8lb (36kg) hammers are made from wearresistant highchrome steel for long service life Production is higher and hammer life is enhanced by feeding 1in (25mm) materialPortable Hammermill Crushers Gilson CoHammer Mill Wear Parts When it comes to Replacement hammer mill wear parts, Qiming Casting has been crushing the market for decades If you demand the peace of mind that comes with ISO 9001certified, fullyguaranteed and warranted replacement parts for your hammer millHammer Mill Wear Parts Wear Parts For Industry

APLIKASI MATERIAL HIGH ALLOY CAST STEEL PADA

Hammer mill is one kind of machine that needs high durability, especially for grinding components such as hammers, The lowest wear rates of this hammers is 014 mm 2/kg iron ore, showed by hammers which had a composition 16%C – 32%Mn – 45% : Mill Liner Bolts Molycop Engineered designs and manufacturers a range of SAG and Ball mill liner bolts for the mining and mineral processing industry Manufactured from carbon alloy steel, we customize our bolts to satisfy our customer requirements Molycop Engineered controls the MOLYCOP ENGINEERED Molycop