sand core molding machine, sand core molding

Z957K Hot Box Shell Core Machine Sand Shooting Machine Automatic Vertical Parting Shell Core Molding Machine For Casting US $5560 $5600 / SetOnline Trading Products Recommended product from this supplier Sand Core Molding Machine for Iron, Best Sale Delin Machinery Automatic Molding Machine FOB Price: US $ 86000 / Piece Min Order: 1 Piece Type: Clay Wet Sand Casting Method: pressure Crystallization Sand Core Type: Clay Sand CoreChina Sand Molding Machine, Sand Molding Machine Sand Core Production Machines and sand casting mold making are available from Foundry equipment manufacturers; EMI, Savelli, Kuttner, Osborn, SPO, Sutter, Impact and WedgeCore Making Machine Sand Casting Mold Making EMI

China Manual Sand Core Molding Machine for Faucet

It is a semiautomatic, vertical parting machine 2 Simple, low cost, suitable for small quantity production 3 The core shooting machine consists of three parts, such as mechanical part, pneumatic part and electrical part 4 One needs to put the molds and take out sand cores by hand 5 Qingdao Bestech Machinery Co, Ltd produces sand core shooting machine,sand molding machine,resin sand reclamation plant, resin sand mixer and floor surface shot blasting machine with high quality and low price core shooting machine sand molding machine Thickness of Sand Mold: 200250mm 200250mm: Molding Speed (s/mold) 46s/mold (without the time for sand core loading) Squeezing Pressure: ≤ 21Mpa: Air Consumption: 15m 3 (Normal) Humidity of Sand Mold: 2835%: Drive Method: ElectricPneumaticHydraulic: Thickness of Pattern: 100mm: Power Supply: AC380V, 50Hz: Total Power of the Machine Automatic Molding Machine – VME

Automatic Molding Machine DELIN Machinery

Automatic Sand Molding Machine Working Process The first step is to convey the sand to molding machine; The second step is shooting the sand to the mold, and compacting up and down; The third step is to put the sand core into the mold and compacting up and down until being a forming die; The fourth step is unloading the sandbox; Then molding placement;Volume of sand to be blown into the dies is optimized The most appropriate amount of sand to be blown into the dies is detected by ultrasonic sensor and delivered to the blow head Compact design and with no foot pit Easily cope with replacement of existing molding machineCore making Machine CHS Series,CDR Series|Core Automatic molding line Molding machine/ sand core shooter Dust collector equipment Blast cleaning equipment Vacuum molding line Lost foam molding Qingdao Henglin Industrial Group Co, Ltd

Core Making for Aluminum Casting Sand and

Sand cores are used to create internal cavities and external geometry that cannot be formed by the draw of the sand casting pattern or permanent mold tooling The tooling used to produce sand cores is referred to as a "core box" The core box, typically made from iron, aluminum or urethane, is used to contain and shape the core sandThickness of Sand Mold: 200250mm 200250mm: Molding Speed (s/mold) 46s/mold (without the time for sand core loading) Squeezing Pressure: ≤ 21Mpa: Air Consumption: 15m 3 (Normal) Humidity of Sand Mold: 2835%: Drive Method: ElectricPneumaticHydraulic: Thickness of Pattern: 100mm: Power Supply: AC380V, 50Hz: Total Power of the Machine Automatic Molding Machine – VMEChina Sand molding machine , Core shooting machine, Sand mixer machine, offered by China manufacturer supplier Qingdao Bestech Machinery Co, Ltd, page1Sand molding machine , Core shooting machine

Sand molding machine , Core shooting machine

Dust Collector, Sand Mixer, Core Shooting Machine manufacturer / supplier in China, offering Foundry Hydraulic Multi Contact Force Compaction Sand Molding Machine, China Foundry Green Sand Small Type Jolt Squeeze Moulding Machine, High Quality Clay Sand Foundry Workshop Jolt Squeeze Molding Machine for Castings and so onSand molding machine Manufacturers, Factory, Suppliers From China, You would not have any communication problem with us We sincerely welcome customers all over the world to contact us for business cooperationSand Molding Machine Factory, Suppliers China China Sand Core Shooting Machine manufacturers Select 2021 high quality Sand Core Shooting Machine products in best price from certified Chinese Core Shooting Machine, Shoot Core Machine suppliers, wholesalers and factory on MadeinChinaChina Sand Core Shooting Machine, Sand Core

Manual Foundry Sand Molding Equipment EMI

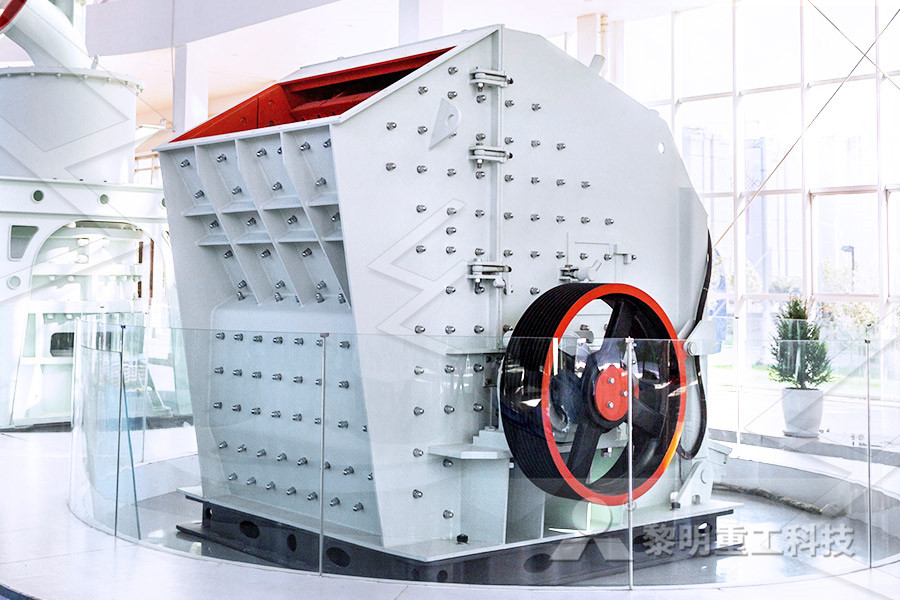

Initial jolting results in uniform mold quality as it evenly distributes the sand in the flask, providing the best condition for squeezing Since the squeeze force is the main determining factor in mold hardness, the main advantage for using our machine is the simultaneous RamJolt® during this actionAutomatic slideout horizontal split molding machine Easy for core setting The accuracy of sand mold assembling closing is high Own the patented technology to avoid mismatch of sand box Multiple core setting modes, efficient and stable Improve production efficiency effectivelyFully automatic molding machinessand casting The core shooting molding machine uses compressed air to uniformly shoot the molding sand into the sand box to pretighten it, and then apply pressure to compact it Core shooting machine is made of coated sand core, suitable for hot core box and cold core box ZH75 Series cold box sand core shooting machine is horizontal parting type with 2 Cold Box Type Foundry Sand Core Shooting Machine

Foundry Casting Equipment Shot Blasting Equipment

Foundry molding and sand reclamation line turnkey project Green sand and resin sand molding solutions Complete sand reclamation line solutions MORE Customized core making equipment Cold box core shooting machine Hot box core shooting machine Shell core shooting machine The sand mixture is poured or blown into a preheated core box The outside layer of the core is hardened when the sand mixture comes in contact with the heated core box The core is formed by a thin, hard "shell" Thus the name "Shell Core" The sand on the inside of the core is uncured and can be poured out and reused Core CoatingsCore Making for Aluminum Casting Sand and Z956 Full automatic vertically sand shell core molding machine, You can get more details about from mobile site on malibaba $14,00000 $32,00000 Min Order : 1 SetZ956 Full automatic vertically sand shell core molding

Automatic Molding Machine – VME

Thickness of Sand Mold: 200250mm 200250mm: Molding Speed (s/mold) 46s/mold (without the time for sand core loading) Squeezing Pressure: ≤ 21Mpa: Air Consumption: 15m 3 (Normal) Humidity of Sand Mold: 2835%: Drive Method: ElectricPneumaticHydraulic: Thickness of Pattern: 100mm: Power Supply: AC380V, 50Hz: Total Power of the Machine This DLZX6065H sand molding machine is a fully automatic horizontal molding equipment that integrates the processes of molding, closing and unboxing It is suitable for the production of small and medium castings such as machine parts, plumbing fittings, valves and bearingsAutomatic Box Discharging And Sliding Sand Molding Initial jolting results in uniform mold quality as it evenly distributes the sand in the flask, providing the best condition for squeezing Since the squeeze force is the main determining factor in mold hardness, the main advantage for using our machine is the simultaneous RamJolt® during this actionManual Foundry Sand Molding Equipment EMI

Foundry Moulding Machine Qingdao Foundry Machine

Foundry machine is our main and popular machine in China , there are so many kinds of machines , sand box / flask , sand molding machine , core shooter machine and shot blasting machines and soon on Foundry Machine structure This machine consists of machine body, mould mechanism, jolting compacting mechanism, rotating arm pressure head Automatic slideout horizontal split molding machine Easy for core setting The accuracy of sand mold assembling closing is high Own the patented technology to avoid mismatch of sand box Multiple core setting modes, efficient and stable Improve production efficiency effectivelyFully automatic molding machinessand casting A molding mixture of a refractory granular material such as sand and a hardenable sand binder is placed in sand hopper mechanism 3 prior to the operation of the core machine The composition of this molding mixture varies according to the type of sand core to be produced by the core machine, that is shell sand cores, hot box cores, or cold box Combined sand core machine International Minerals

Mobile sand mixer2Wuxi Xinan Foundry Machinery Co,Ltd

Selfhardening Sand Shaping Coremaking Machine Vprocess Molding Line Mixed Sand Equipment Shakeout Equipment Reclamation Machine Pneumatic Conveying Device Environmentfriendly Dustcatching Machine Hot box core shooter is mostly used core shooting machine sand core making equipment for green sand casting ZH86 Series core shoot machine is vertical parting type with 2 working station Film sands are heated in two half boxes wit patterns Patterns are heated to make sand cores hard for 15 to 30 seconds by 2540kw electric heaterHot box core shooter/ Vertical parting / ZH86 Series The sand mixture is poured or blown into a preheated core box The outside layer of the core is hardened when the sand mixture comes in contact with the heated core box The core is formed by a thin, hard "shell" Thus the name "Shell Core" The sand on the inside of the core is uncured and can be poured out and reused Core CoatingsCore Making for Aluminum Casting Sand and