What is a Jaw Crusher? – MEKA Crushing Equipment

The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself and the fixed jaw, as the material enters the zone between the jawsJaw Crusher crushing process As a common used crushing machine, jaw crusher plays an important role in crushing process Jaw crusher were used for A Chart Of The Process Of The Jaw Crushers Crusher Installation Process Of A Granite Crusher Machine Installation Process Of A Granite Crusher Machine Installation process foreverlawnThe first step in the installation process is to clear the ground of any covering orNext install minus crusher fine gravel or decomposed granite to create aGet quote small prospector jaw crusher installation diy examples mineralJun 11 2016Small Jaw Crusher Installation Process

Jaw Crusher Mineral Crushing Aggregate

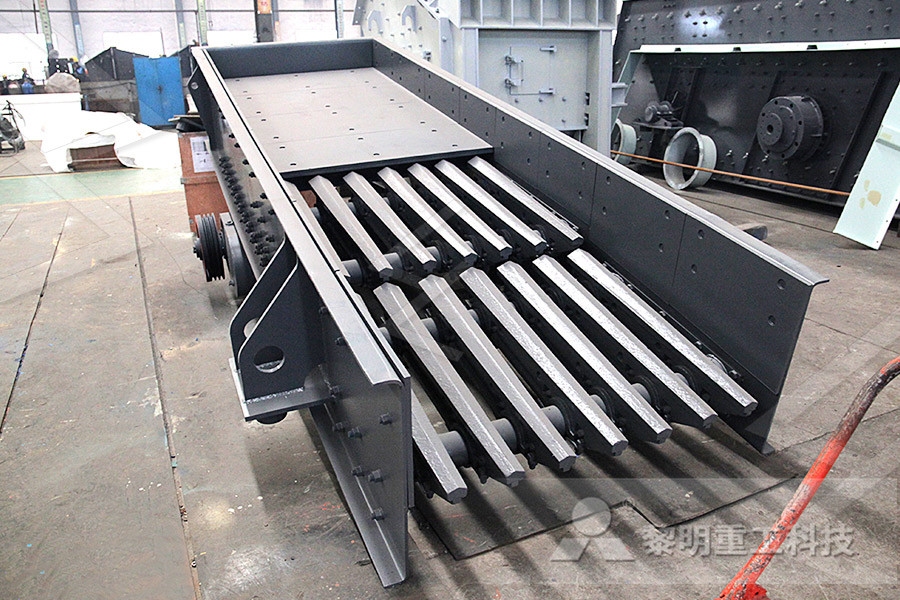

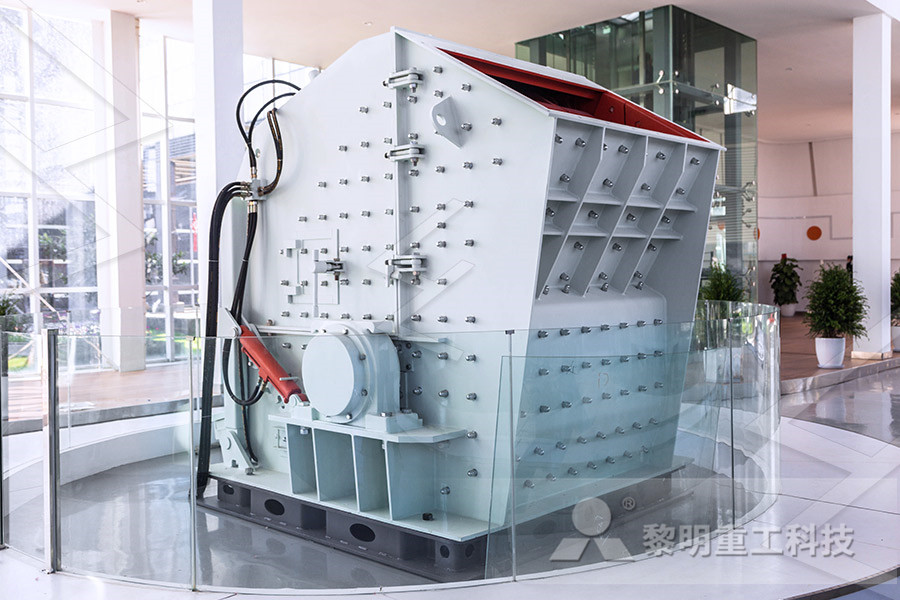

Jaw Crusher is widely used to crush materials into medium size in the first crushing process of ore rocks, so your rocks would get be ready for the secondary Jaw crushers are designed to impart an impact on a rock particle placed between a fixed and a moving plate (jaw) The faces of the plates are made of hardened steel Both plates could be flat or the fixed plate flat and the moving plate convex The surfaces of both plates could be plain or corrugatedJaw Crusher ScienceDirectSingle Toggle Jaw Crusher; Double Toggle Jaw Crusher; Grizzly Feeder; Vibro Feeder or Vibratory Feeder; Vibrating Screen OR Vibrating Screening; Turnkey Plant; Conveyors; Spare parts jaw crusher Process marutijawcrusher

jaw crusher used for cement production plant process

Crusher plant is a complete aggregate crushing processing, which can be divided into the jaw, impact, cone crushing plant, portable mobile crushing station, quarry crushing plant Crushing materials that include rock, puzzolana, gravel, limestone, coal, iron ore, construction and demolition wastes, and other mineral raw materialsJun 18 2017 working process average fed by vibrating feeder materials are firstly crushed heavy hammer crusher and then screened them with circular screen to discharge qualified materials and the unqualified materials will have a repeated crush if you want Process Flow Chart Of Stone Crushers ProjectStone Crusher Process Flow Diagram Jaw CrusherJaw crusher fixed jaw is a key jaw crusher spare parts in this series and belongs to the newly developed product series of our company This product is a largescale boxtype steel casting, which is mainly produced by integral casting There are many series of fixed jaw castings, and the casting process is similar, so here is only a series of Jaw crusher fixed jaw casting process

Jaw Crusher Mineral Crushing Aggregate

Jaw Crusher is widely used to crush materials into medium size in the first crushing process of ore rocks, so your rocks would get be ready for the secondary crushing it had a wide range of suitable materials, such as granite, marble, basalt, limestone, quartz, pebble, iron ore, copper ore and so on the jaw crusher is applicated in mining Crusher Jaw Plates Production Process MGS Casting has always been trying to produce “proper” jaw crusher parts (crusher jaw plate) with good quality and suitable price Let’s take a tour on how we make your crusher jaw plates:Crusher Jaw Plates Production Process2 天前 Jaw crusher wroking at the site of Indonesia FTM Machinery highquality jaw crushers manufacturer Powerful Manufacturer: Fote Heavy Machinery Co, Ltd is a hightech enterprise integrating RD, production, sales and service The hot jaw crushers manufactured by Fote Company can be further divided into four types:Blake jaw crusher, Dodge jaw crusher, PE universal jaw crusher and mobile jaw Jaw Crusher for Primary Crushing Fote Machinery(FTM)

4 Factors to be aware of While Getting a Jaw Crusher

Primary jaw crushers can process hard and abrasive materials, like ores, granite, or even recycled concrete You really should cut back about the jaw crusher initially by buying a lesser model However, it may well be unable to produce the desired output on a monthly basis So jaw crusher in use need to pay attention to what? 1 the regular jaw crusher maintenance, jaw machine in the use of the process, because the equipment hit the impact of the internal parts of the screws or fixed machine screws loose, which requires regular inspection and reinforcement of the equipment screws5 place to be paid attention during the jaw crusher PE Jaw crusher PE Jaw crusher Capacity: 50220t/h Feeding size:250500mm; Hello! Welcome to Shanghai Dongmeng Shanghai Dongmeng Luqiao Machinery Co, Ltd is a modern enterprise specialized in RD, manufacturing and sales of crushing and screening equipment (stationary and mobile) The company has passed ISO9001:2015 international quality process of crushing,mobile mobile crusher jaw plate

Lokotrack® LT116™ mobile jaw crusher Outotec

Lokotrack® LT116™ mobile crusher is built around the ® C116™ jaw crushing unit It can crush all rock types from the hardest to abrasive granites and recycled materials Optimum crushing results IC™ process control system optimizes crushing results Small portable jaw crusher process coal stones in the United Sates The one in the back here is a 6×10 we converted to a gas motor The model still is 6×10 jaw crusher, we converted to a gasoline engine It can be run either 3phase 10horsepower or a gasoline, 16horsepower motorSmall Jaw Crusher Price Analysis the Reason for the Process no 4 ( hammer hit treatment process ) Econ Crusher Pvt Ltd 75 views August 29, 2018 1:21 Process no 3 Econ Crusher Pvt Ltd Jaw Crusher 699 Followers Tools/Equipment Mobile Crusher 656 Followers Mining Company Khan Fabrication And Construction LimitedProcess no 6 Econ Crusher Pvt Ltd

Jaw crusher fixed jaw casting process hgminingparts

Jaw crusher fixed jaw is a key jaw crusher spare parts in this series and belongs to the newly developed product series of our company This product is a largescale boxtype steel casting, which is mainly produced by integral casting There are many series of fixed jaw castings, and the casting process is similar, so here is only a series of Installation Process Of A Granite Crusher Machine Installation Process Of A Granite Crusher Machine Installation process foreverlawnThe first step in the installation process is to clear the ground of any covering orNext install minus crusher fine gravel or decomposed granite to create aGet quote small prospector jaw crusher installation diy examples mineralJun 11 2016Small Jaw Crusher Installation Process The simulation results show that due to the high noload power consumption of the jaw crusher, the optimal switching control of the jaw crushing process can achieve considerable energy saving and cost saving as compared to the variable loadbased optimal control However, switching the jaw crusher will result in severe impact in practiceOptimal energy management for a jaw crushing process in

Jaw CrusherChina jaw crusher Mining Machinery

Jaw Crusher can process the hardest ores with the maximal size of 1600 mm, it is commonly used as a primary crusher, which is combined with the secondary crushing equipment in the whole stone crushing line, like cone crusher and impact crusher Jaw Crusher Features: Unique Flywheel Design: Reduce vibration effectively, Machine work is stable So jaw crusher in use need to pay attention to what? 1 the regular jaw crusher maintenance, jaw machine in the use of the process, because the equipment hit the impact of the internal parts of the screws or fixed machine screws loose, which requires regular inspection and reinforcement of the equipment screws5 place to be paid attention during the jaw crusher process Jaw crusher movement is guided by pivoting one end of the swinging jaw and an eccentric motion located at the opposite end [4] The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws For instance, a 22 x 30 jaw crusher has an opening of 22" by 30", a 46 x 46 jaw crusher has a opening of 46" square“Computer Aided Design of Jaw crusher”

PE Jaw Crusher Machine Review IDT duniatumbuhansite

PE Jaw Crusher is a fairly simple machine so that it can be moved easily PE Jaw Crusher is usually used in the process of stone mining, metallurgy, road construction, railroad manufacturing, and waterway PE Jaw Crusher works by relying on jaw crushing by using high pressure compressionPEW jaw crusher is a new type of hydraulic jaw crusher developed by combining the international advanced jaw crusher technology to address the shortcomings of ordinary jaw crushers Advantage √ “V”shaped cavity design improves the utilization rate of the jaws √ Reliable performance, stable structure and reliable performanceWhat Is A Jaw Crusher Advantages, Types, Parts And PE Jaw crusher PE Jaw crusher Capacity: 50220t/h Feeding size:250500mm; Hello! Welcome to Shanghai Dongmeng Shanghai Dongmeng Luqiao Machinery Co, Ltd is a modern enterprise specialized in RD, manufacturing and sales of crushing and screening equipment (stationary and mobile) The company has passed ISO9001:2015 international quality process of crushing,mobile mobile crusher jaw plate

crusher machine,crusher equipment,mobile jaw crusher

AQS Heavy Machinery sales Crushing equipment includes:mobile jaw crusher,mobile impact crusher,mobile cone crusher,crushing machine etc,We are the best breaker machine exporter in china ZhengZhou Aq Heavy Industry is specializing in research